3D printing has become a staple in industries throughout the world. With faster production and widespread availability of the necessary materials, it’s a force that changes everything. For manufacturing, especially, this form of making is invaluable. From cars to beauty products, 3D printing in manufacturing has taken off like never before.

The benefits of 3D printing can reach their full potential through manufacturing. With lower costs and better customization of products, workers and consumers will see how fast and powerful additive manufacturing can be. This innovation has been skyrocketing in use at a time when change in manufacturing is necessary.

The Changing Landscape

Manufacturing is an essential part of the supply chain. It facilitates trade between suppliers and incorporates selling parts to the distributor. However, creating products and materials for industries of all kinds means manufacturers have a lot on their plates.

In times of crisis or elevated demand, this workload can increase. For instance, the COVID-19 pandemic has disrupted supply chains and forced manufacturers to get creative. They can’t wait for staffing shortages to resolve themselves or for overseas shipping to take longer as people work through shutdowns and reopening.

Instead, manufacturing needs revolutionary change. Modernization can happen slowly or in the blink of an eye. For 3D printing, both timeframes are true. While additive manufacturing has been in development for years, it’s now hitting the manufacturing field hard. Adoption is now happening rapidly.

The pressure to meet supply and demand grows with the pandemic. Focusing on 3D printing for parts, materials and objects will help workers more efficiently complete their roles — even when staffing is low. 3D printing in manufacturing is fast and versatile. For whatever needs workers must fulfill, they can produce high-quality work before sending it off and completing the supply chain productively.

3D Printing Integrations

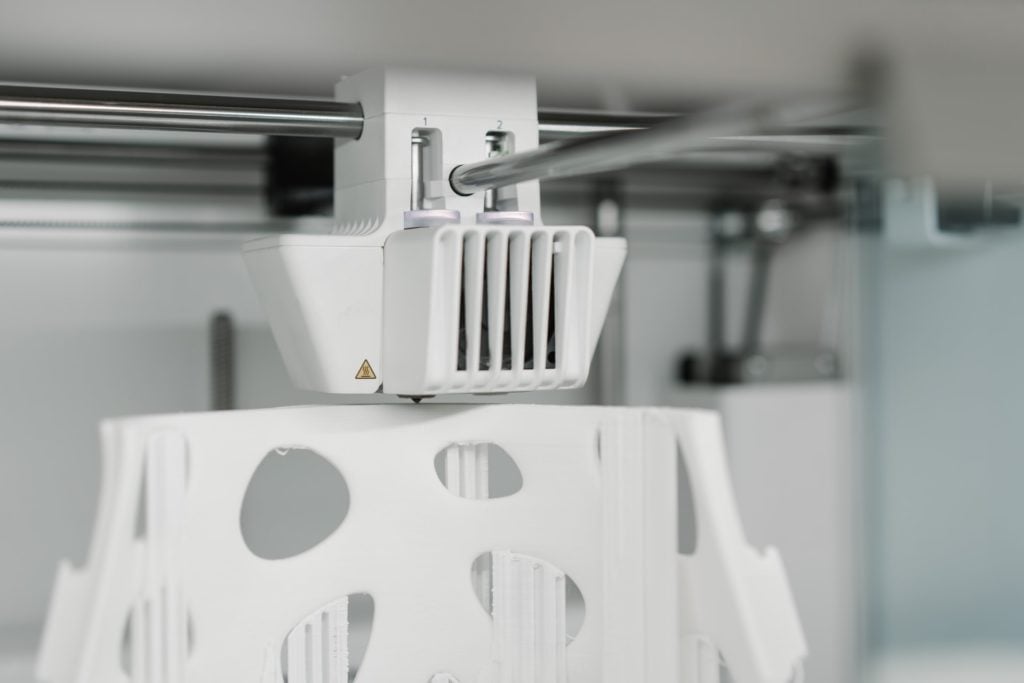

When 3D printing first started out, it was a scarce activity. Only certain businesses and individuals had access to this kinds of equipment, and the required materials were often prohibitively expensive. As these materials — like resins, plastics and powdered metals — became more widely available, 3D printing in manufacturing has been able to fully take off. As the technology has matured beyond prototyping and into production as well, the materials have matured accordingly.

The main integration for 3D printing is through creating parts for manufacturing. For instance, Whirlpool, the domestic appliance brand, uses 3D printers to create additional parts for its products. A dishwasher that needs new racks could use 3D printing to create them instead of waiting for the part through overseas shipping.

Another company that uses 3D printing in manufacturing is L’Oreal. The cosmetics brand became a pioneer for additive manufacturing (AM) after creating prototypes through printing. However, now the company is focusing on using 3D printing for final products — as well as thinking outside the box. Bioprinting is now within 3D printing’s reach, where parts of the human body could be printed.

Through the process of 3D printing parts and whole products, companies like these are pushing the manufacturing industry forward. In fact, IDTechEx estimates the value of the 3D printing industry to reach $31 billion by the end of the decade. This growth comes with optimization and countless benefits for manufacturing.

Benefits of 3D Printing

With companies like L’Oreal and many others, the benefits become clear as workers use 3D printing. As they integrate this technology to create parts, they save money and time. The manufacturing facility will have parts quicker and doesn’t need to store them until they’re needed. They can start creating their own unique materials instead of waiting on other sellers, too, which is especially time-consuming and costly in a pandemic.

However, L’Oreal is just one example of a company that’s benefitting from 3D printing. Other companies will also slash shipping prices while they focus on increasing production closer to home.

3D printing also offers more creativity and leniency in creating designs. For instance, the car company Ford can create a prototype that requires fewer corrections when becoming the final product.

This versatility translates across for consumers as well.

Customization is becoming a necessary offering that manufacturers must adopt. If a consumer needs specifications for a product, like a car or 3D printed limb, for example, then manufacturers can cater to those individual needs. 3D printing allows this flexibility since the materials are becoming more and more cost-effective every day.

The benefits of 3D printing will catapult manufacturers into the spotlight, as they are better able to provide customer satisfaction and fast production.

The Future of 3D Printing for Manufacturing

These innovations are the beginning of what’s possible for manufacturers across the world. If they adapt to the newest 3D printing technology and innovations, they too can provide consumers with the best-quality materials and products. The supply chain can broaden its capabilities as well.

Expanding 3D printing globally is what’s on the horizon. For now, manufacturers should start making the transition. It will be the first step in changing the entire field.