Charles R. Goulding and Preeti Sulibhavi look at the growing usage of 3D printing at Men’s Sheds.

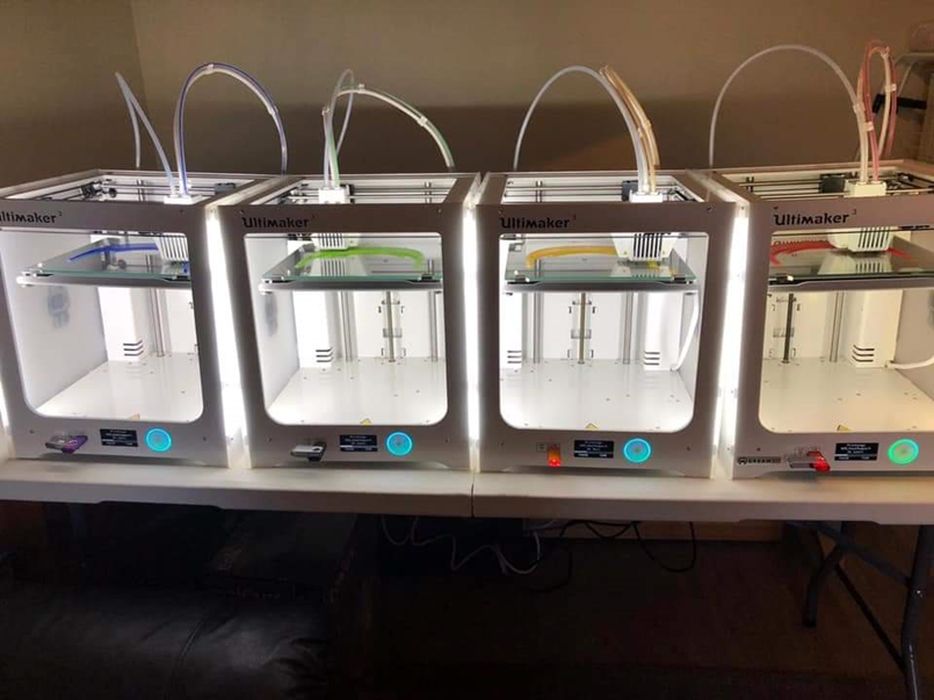

Men’s Sheds are community spaces where men can come together to work on projects, share skills, and socialize. These spaces are typically focused on activities like woodworking, metalworking, and other tooling activities as well as manual crafts. Now, with the advent of accessible 3D printing technology, Men’s Sheds have the opportunity to incorporate this new technology into their activities.

We have previously written about she sheds and 3D printing on Fabbaloo. We have also covered some components of she sheds including, lighting, furniture, artisanal pieces and gardening elements, and explained how 3D printing can help achieve high quality results.

3D printing can be a great addition to men’s sheds for a few reasons. First, it allows for a new set of skills to be learned and shared among members. 3D printing requires knowledge of design software, as well as an understanding of how to operate and maintain a 3D printer. This can be a great opportunity for members to learn and share new skills.

Additionally, 3D printing can open up new project possibilities for men’s sheds. With a 3D printer, members can create objects that may be difficult or impossible to create using traditional woodworking or metalworking techniques. This can allow for a wider range of projects and can also allow for more intricate and detailed designs.

In addition to its practical applications, 3D printing could also be a great way to introduce new members to the men’s shed. Many people are fascinated by the technology and would enjoy learning how to use it. By offering 3D printing workshops and training sessions, Men’s Sheds could attract a whole new generation of members who are interested in digital fabrication.

Overall, while 3D printing might seem like a departure from the traditional manual skills practiced in Men’s Sheds, it could actually be a valuable addition to the space. By combining traditional techniques with cutting-edge technology, Men’s Sheds could continue to evolve and thrive for years to come.

3D printers can even be used to help build men’s sheds themselves. A 3D printer could technically build a tiny house in less than 24 hours for under US$10,000, a men’s shed is certainly within reach.

Finally, 3D printing can be a great way for men’s sheds to give back to their communities. Members can use their 3D printing skills to create objects for those in need, such as prosthetic limbs or other medical devices. This can be a great way for men’s sheds to use their skills for good and make a positive impact in their communities with a charitable component to their mission.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Overall, incorporating 3D printing into men’s sheds can be a great way to expand the skills and projects available to members, while also allowing for the creation of objects that can benefit their communities. By combining traditional techniques with cutting-edge technology, men’s sheds could continue to evolve and thrive for years to come.