Researchers have been developing methods of 3D printing electronic circuits for use in high temperature environments.

This is a relatively new field, as it has been challenging to produce electronics for placement in, say, aircraft engines or other environments where temperatures would easily fry, melt or even vaporize conventional electronics.

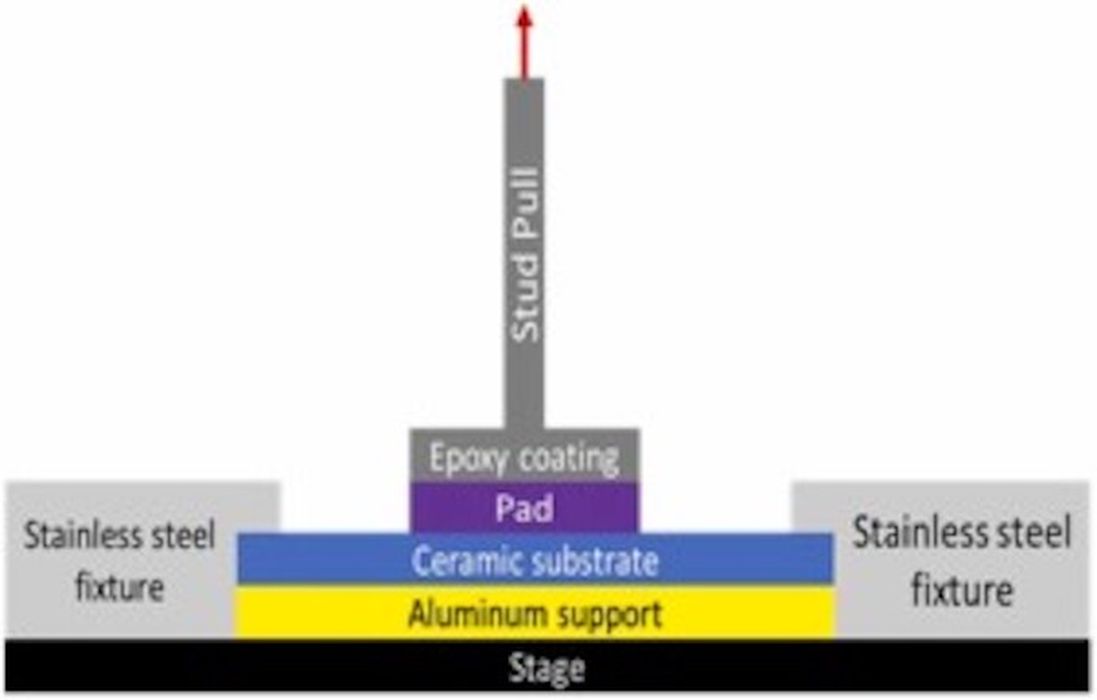

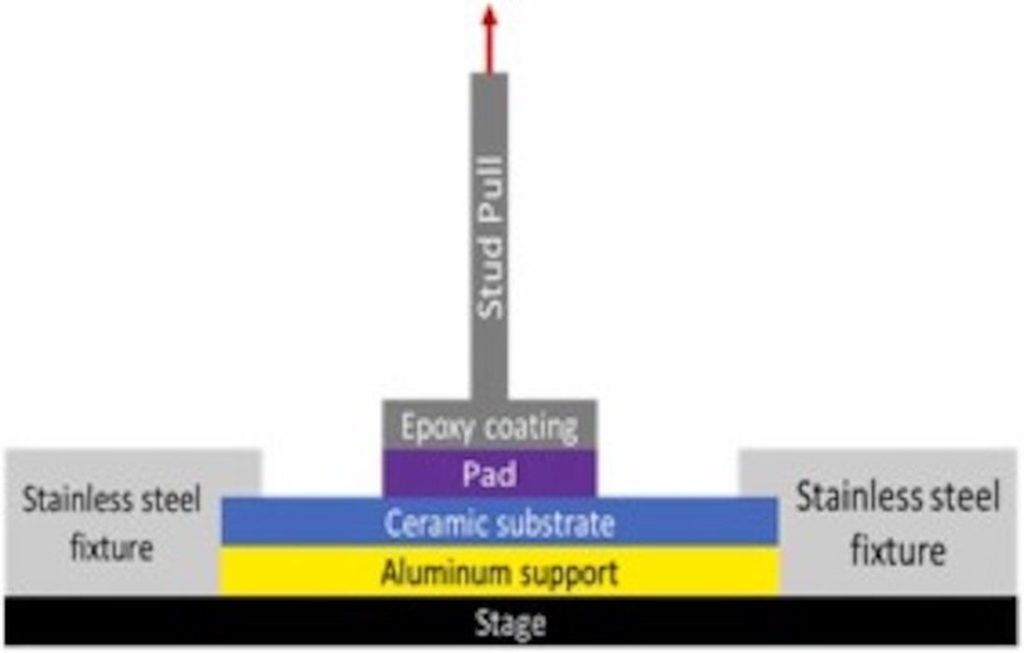

But how is this accomplished? It turns out the researchers used an aerosol jet process to deposit gold-based electrical structures on a ceramic substrate made from alumina. Both of these materials are well able to withstand extreme temperatures in the desired range.

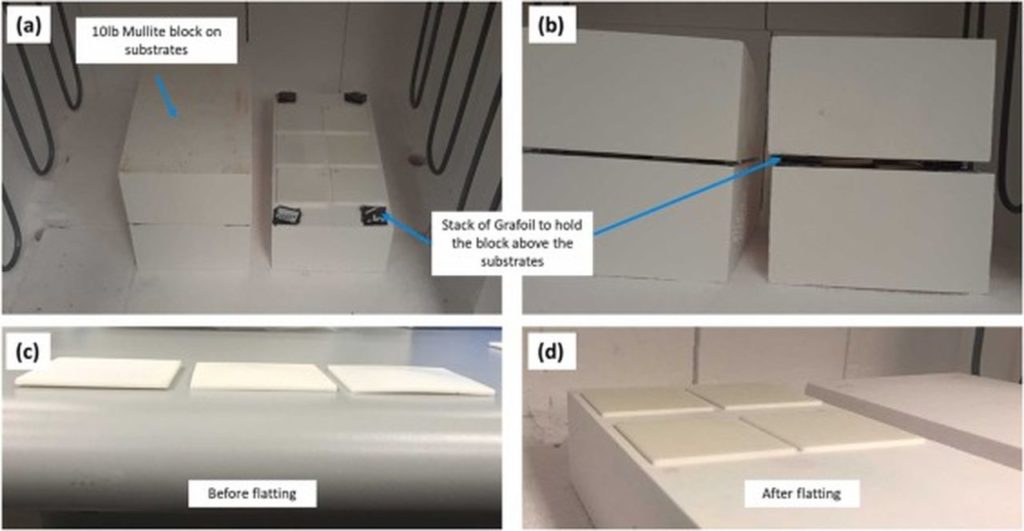

The substrate was produced using a DLP process where a ceramic photopolymer resin was solidified into the target shape.

It’s not as simple as just planting down conductive material and checking whether an electrical current can travel along the circuit paths. In fact the research has to identify the dielectric constant of the structure to ensure it is suitable for application use, and not only that, it must be measured at different temperature ranges.

The researchers found their approach yielded a circuit that could still operate at temperatures up to a blistering 750C. In fact, they were able to 3D print a conformal broadband antenna that worked successfully at an astonishing 850C.

However, they found the dielectric constant tended to decrease as the temperature rose.

What is the importance of this research? They explain:

“This work presents an entirely additive manufacturing-based approach to fabricate electronic components including substrates, interconnects, and RF elements for high temperature applications.”

The implication here is that complex structures that can only be produced using additive approaches can now be made for high temperature electronics applications. Applications could include sensors, anntennae or other electronics within engines, factory equipment, power plants and other instances of high temperature environments.

One interesting angle not mentioned by the researchers was space exploration. Earth’s closest planetary companion is actually Venus, not Mars, where most of humanity’s exploration takes place. This is because the surface of Venus is under tremendous atmospheric pressure (100atm) and extraordinary heat.

The average surface temperature on Venus is a whopping 450C — but that temperature is actually lower than the temperatures explored by the researchers. This suggests they may have found a way to create complex electronic components for future Venus surface exploration missions.

Via Science Direct