Charles R. Goulding and Preeti Sulibhavi suggest increased use of 3D printing to alleviate a plumbing parts shortage.

The plumbing parts supply chain problem is continuing into the 2023 heating system. When a family learns that a component needed for their heating season is unavailable for weeks or even months, they are left in a precarious situation.

Frank Mima, general manager of boiler rentals at the Boileroom Group, based in Long Island, NY is quoted as saying, “We get calls every day – two or three calls a day at least – of people looking for temporary boilers…the demand is very high, the problem is there’s no inventory.”

There are HVAC alternatives to steam boilers for radiator systems. Facade-mounted heat pumps, air-based heat pumps (ASHPs), or hot water radiators are the next items to turn to in these situations. But the plumbing required to convert from steam-based to water or air-based systems is also in short supply and the conversion is not always so simple.

The stories can be read on almost any local news outlet. Homeowners are left with no heat or hot water in the dead of winter, inconvenienced due to broken or malfunctioning boilers. Residential boilers are expensive. Building owners are challenged to source parts since much of urban housing is from antiquated buildings, built decades ago with a variety of systems. Slant Fin, a long-time major boiler manufacturer since the 1940s, went out of business in 2022, which has left many building owners in a difficult situation.

Many residents ultimately turn to space heaters, which if electric and left on unattended pose great fire hazard risks. What is the solution?

Boilers and 3D Printing

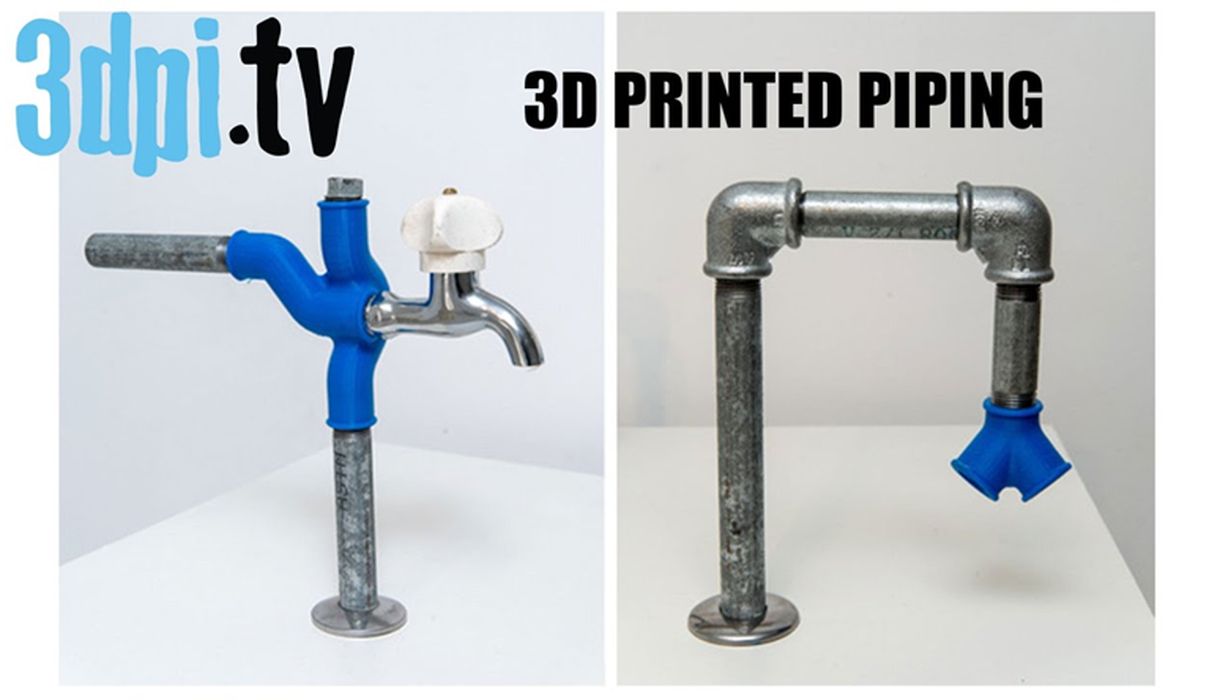

Boiler parts include burners, aquastats, supply lines, return lines and circulator pumps. And we have covered how 3D printing can be used to fabricate 3D printed plumbing components. Especially, during these times of supply chain disruptions, using 3D printers to create replacement parts quickly and economically is a high-quality, viable option.

According to a US Boiler report, the capability to 3D print parts that are not currently in supply, like old faucet systems, for the plumbing side of HVAC businesses, would be of great value and the possibilities for design and complex geometries are endless.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

What This All “Boils” Down To…

The use of 3D printers is a timely and effective solution to the current national boiler parts shortage. Many HVAC and plumbing components can be 3D printed so there is an opportunity to stay warm.