Our testing of the Sovol SV01 Pro 3D printer concludes with a look at print quality and final thoughts.

This is part three of a three part series, please read parts one and two.

Sovol SV01 Pro 3D Printer Software

The software provided by Sovol for the SV01 Pro to prepare print jobs is in fact Ultimaker Cura.

Unfortunately, it is provided only in Windows form, which is not good for anyone running Linux or Mac OS. That happened to be my situation.

This is a common practice by hardware manufacturers that aren’t able to build their own slicing software, and it is best to tag up with a powerful software partner such as Ultimaker Cura.

However, it seems that the version of Ultimaker Cura software used by Sovol is old. I checked the version number of the software, but found it to be 1.3.0, which is definitely not an Ultimaker Cura version, but instead is the version of Sovol’s cloned version. So I could not precisely identify the base Ultimaker Cura version used.

In these cases you really want to use the most up-to-date Ultimaker Cura, because there are some really fabulous new features, such as the Arachne slicer, etc. I decided I would use a modern version of Ultimaker Cura for this test.

I was able to launch Ultimaker Cura version 5 on my Mac, and then also launch the Sovol version under VMWare Fusion. I could then export/copy the machine profiles over to the modern Ultimaker Cura.

3D printer manufacturers using Ultimaker Cura should really just provide a profile that can be imported into the current version of the software and not burden operators with older software.

Anyhow, I found this process to work well, and I was able to easily produce printable files with Ultimaker Cura version 5. I did give SuperSlicer a try as well, in order to use some of its amazing tuning tools, but was unable to get it to work.

Sovol SV01 Pro 3D Printer Print Results

I printed quite a few items on the SV01 Pro, and found the results to be mixed.

Starting with PLA, the easiest material to print, I was able to print multiple items successfully, both with the supplied white PLA, as well as some high quality third party filament.

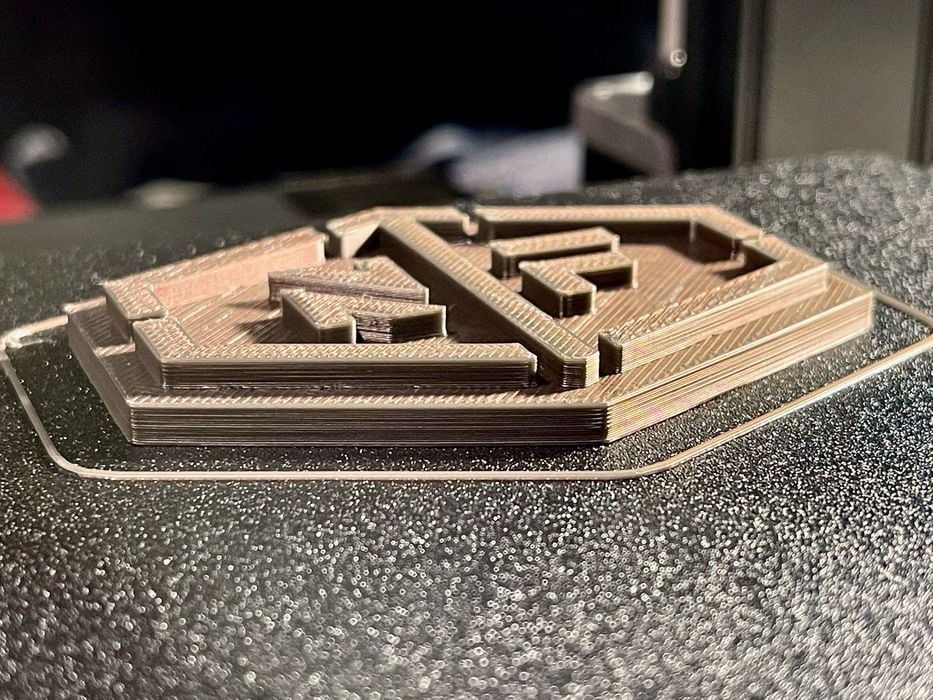

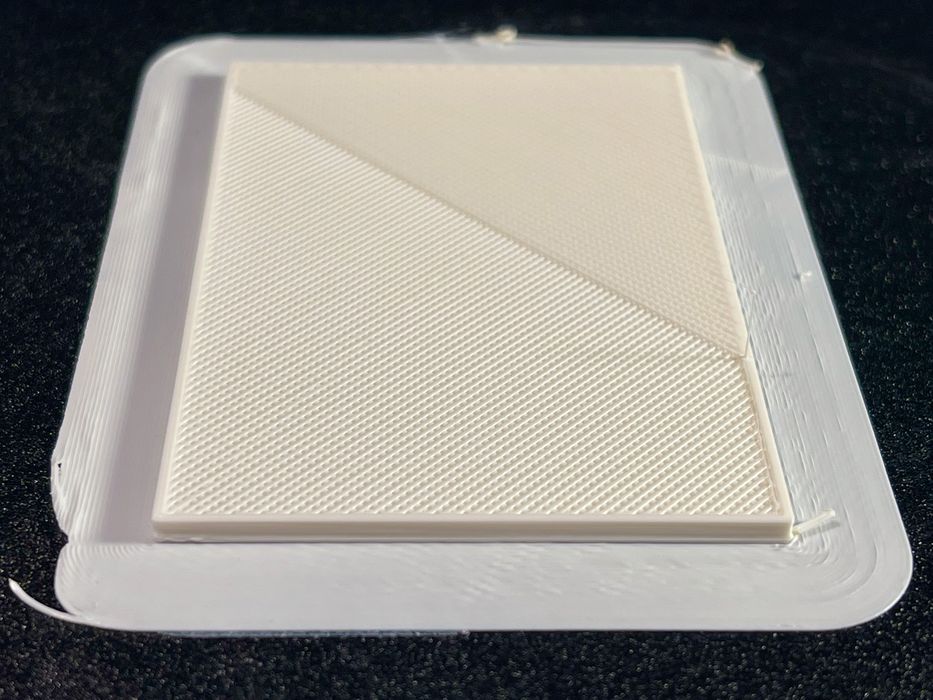

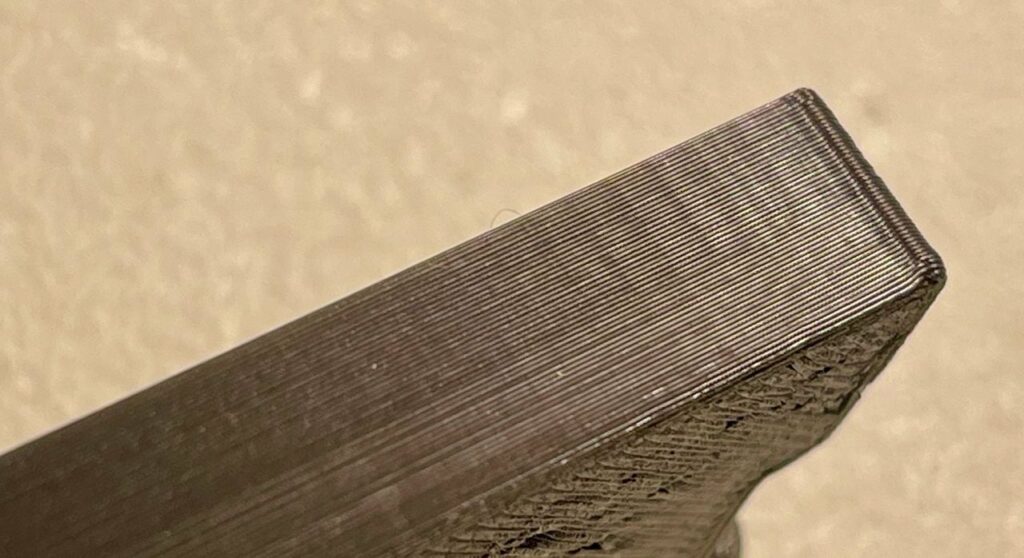

Some of the prints turned out quite well, like this metric bolt measuring device.

This PLA print turned out very well, and had quite crisp edges.

I decided to give the SV01 Pro a good retraction-oriented print, so I chose the classic Nervous System light fixture.

I was a bit nervous myself to see if this print worked, but it printed through very well.

The result was pretty good, and there were minimal strings between the retraction points.

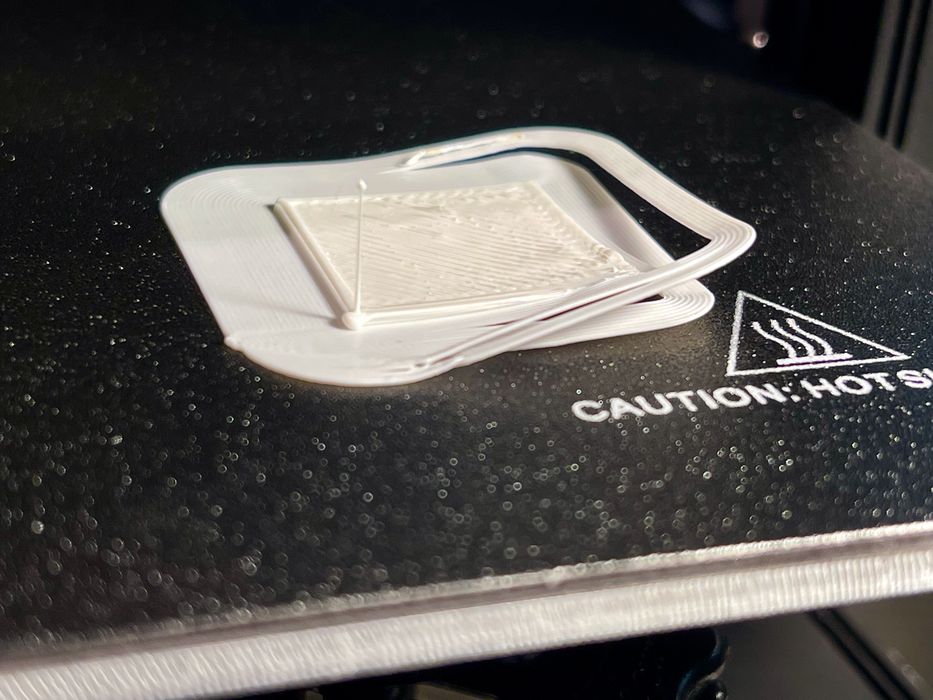

I attempted a twelve hour print to see if the machine would be able to handle longer jobs. It turned out the job was only nine hours due to the job duration estimation issue described above, but it was still completed.

This long print finished, but I did notice some warping on one side (it’s part of a reusable filament spool). This evidently lifted off the surface that I had just washed and re-leveled. I’m not happy with the SV01 Pro’s print surface.

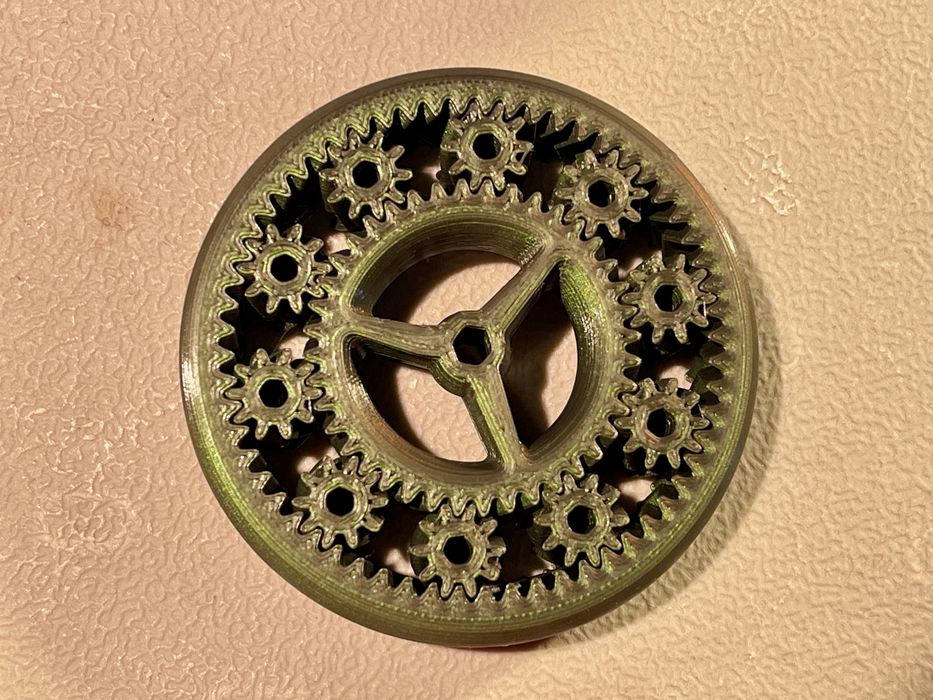

For accuracy, I printed the Planetary Gears 3D model, which is a set of gears that should rotate freely if the print comes out with sufficient quality.

Unfortunately, the gears were frozen. An inspection of the top shows that there were sufficient gaps to allow movement as above.

However, on the bottom some of the parts were mushed together on the first print layer. That might be because the Z-gap is too tight? But if I loosen it, I risk not sticking to the platform, so this 3D model can’t be 3D printed successfully. You can see how the print surface becomes really important here.

I moved on to other materials, beginning with ABS, which is one of the several materials said to be printable on the SV01 Pro. ABS is notoriously difficult to 3D print on open gantry machines like the SV01 Pro, so I wasn’t expecting much.

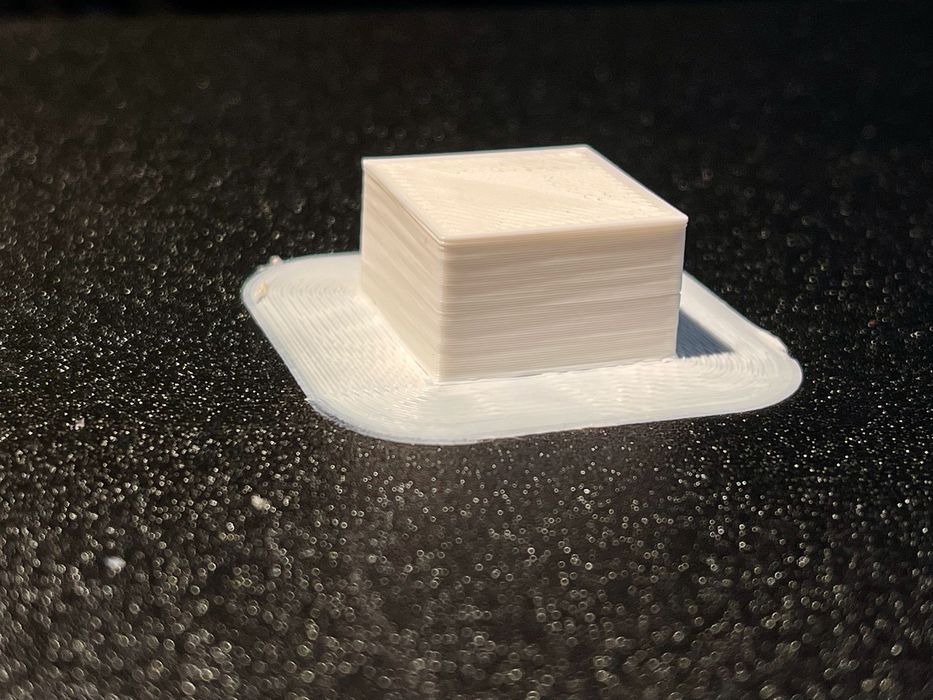

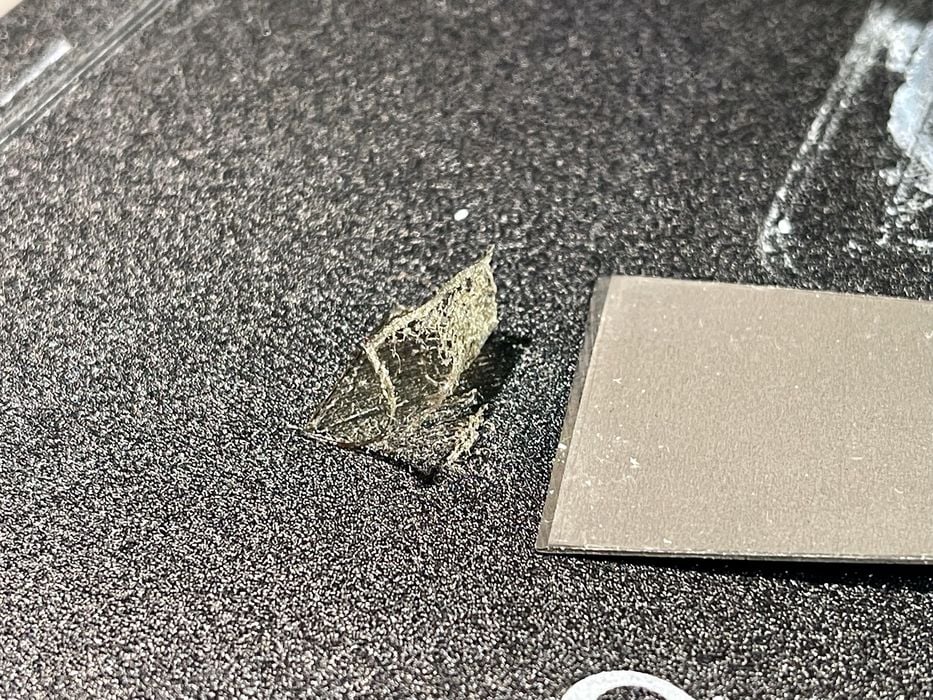

My first attempt failed miserably, as the small cube didn’t stick to the print surface.

A second attempt with a brim also didn’t work. This trick usually works, but it did not with the SV01 Pro. I then re-leveled the bed and repositioned the print to the center where the Z-gap is most accurate.

It worked! I was able to 3D print this small ABS cube. I then attempted to print some larger ABS objects.

Unfortunately, I could simply not get ABS to work properly with this print surface. Even worse, it would leave a thin coating of ABS on the surface that I could not remove, as I mentioned above.

[UPDATE: Sovol explained to us that they recommend using an enclosure for ABS prints, which would capture heat and reduce the thermal gradient that causes warping. Unfortunately were not able to test this method during our evaluation.]

I attempted to remove the ABS by printing a block on top of the debris to fuse and pull it all out, but while the block print worked, it didn’t remove the ABS at all, so my print surface is permanently polluted with ABS.

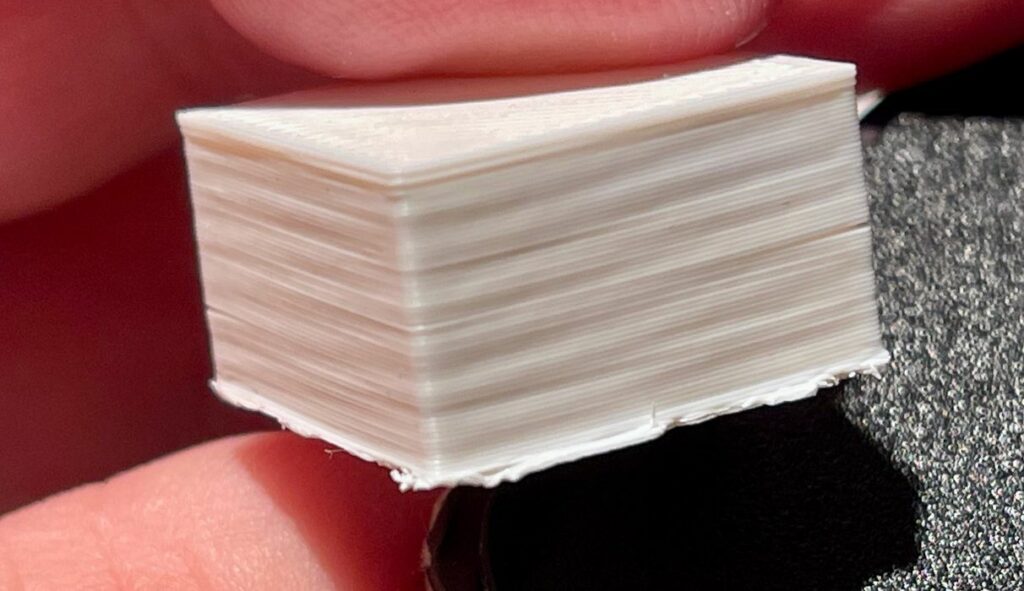

I noticed a couple of effects while printing these objects. Here on the ABS cube you can see a strange rising spiral pattern on the surface when the light hits it just right. I’m not sure what caused this effect, but it is likely an artifact of the motion system design, specifically the Z-axis.

On this print we can see some very slight ringing around the corners. That’s probably acceptable for mechanical part printing.

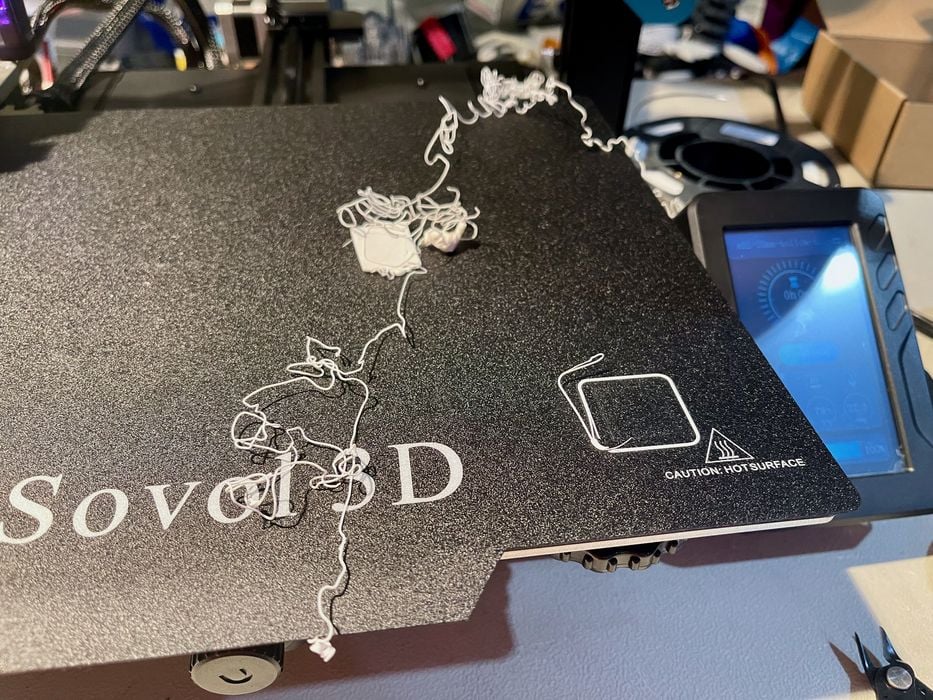

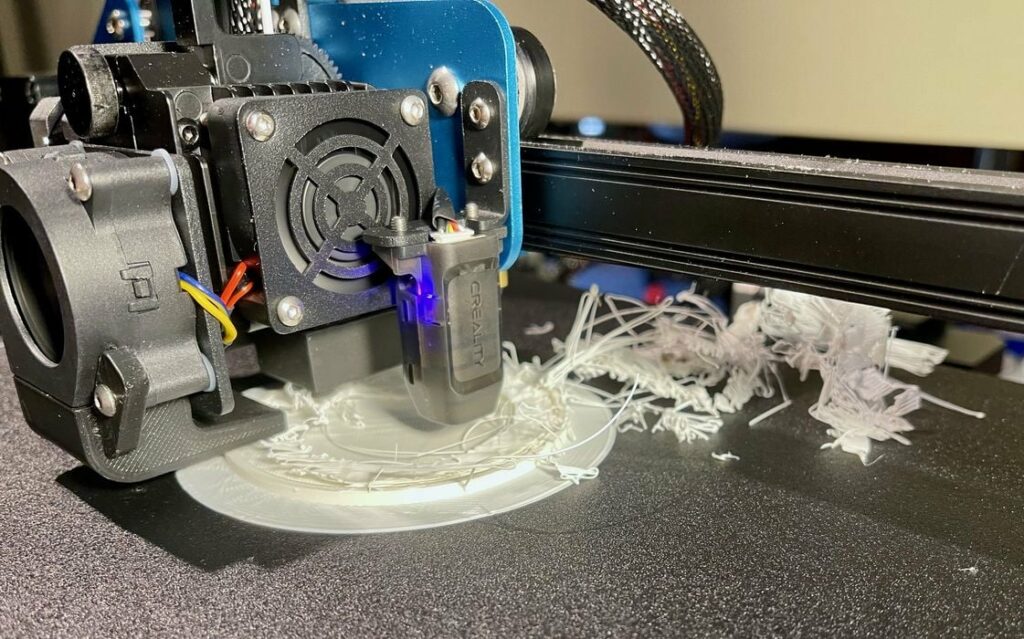

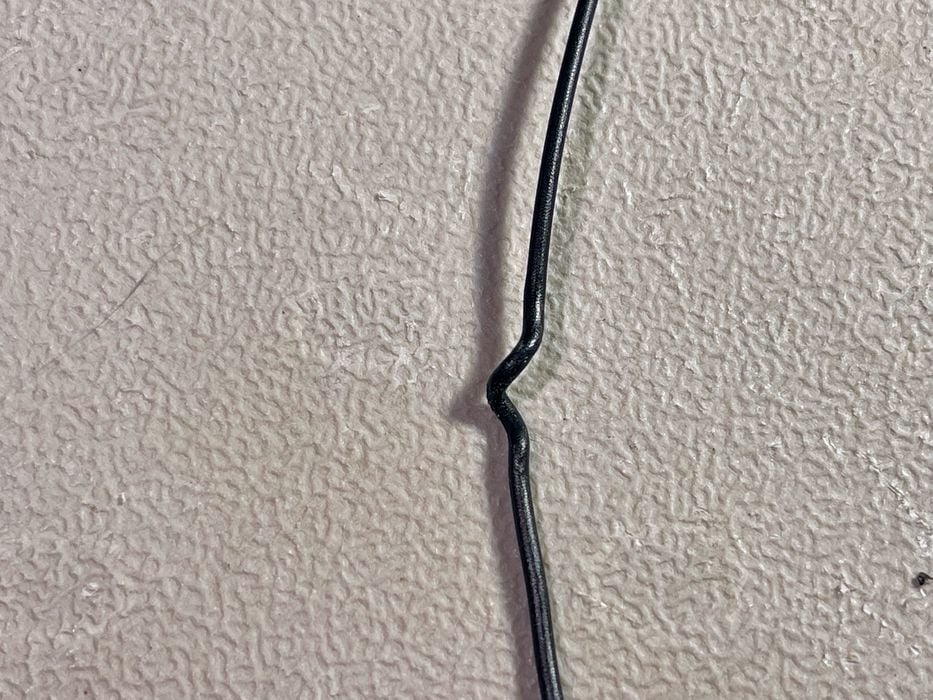

Finally, I moved on to flexible filament, but didn’t have any success. The SV01 Pro includes a direct extruder, which should allow use of flexible materials. After multiple attempts the machine would print only the first layer and then jam.

I gradually slowed the print speed to try to avoid the jams, but, alas, even at the snail-like speed of 20mm/s the flexible filament would jam, and I’d pull out a strand that looked like the above each time.

My thought is that the SV01 Pro could actually be far more successful with these alternate materials if the print surface were improved. I think even a glass surface would have been more usable.

Sovol SV01 Pro 3D Printer Final Thoughts

The Sovol SV01 Pro desktop 3D printer is a relatively inexpensive device sporting quite a few advanced features for a machine at that price point. Print quality for PLA material is decent, but not outstanding.

Due to the problems with the print surface, I found the machine to be practical only for 3D printing standard PLA materials. If one wished to print other materials, I recommend changing the print surface to an alternative system.

SOVOL

SV01 PRO 3D PRINTER

★ BEGINNER 7/10

★ ENTHUSIAST 6/10

★ PRODUCTION 3/10

BEST FEATURES

✔︎ Touchscreen

✔︎ PLA spool included

✔︎ Advanced features

QUESTIONS

✖︎ Poor print surface

✖︎ Print time estimates

✖︎ Filament removal

This is part three of a three part series, please read parts one and two.

Via Sovol