With great anticipation, we have been able to test our first machine from Bambu Lab, their new mini A1.

This is part one of a four part series, please read parts two, three and four.

Bambu Lab A1 mini Background

Bambu Lab is easily the most disruptive force in the 3D print industry today. Their sudden entry and savvy combination of advanced technologies and truly competent user interfaces has gained a huge following.

This is unsurprising, as the company was founded by many who came from DJI — the company that transformed drones from a curious technology into proper consumer and professional devices. Now, it seems, they are doing the same to 3D printing.

The company’s first products were targeted at the prosumer and professional markets, where they gained a huge following due to the reliability, speed and high quality of prints.

Earlier this year the company shocked the industry with their surprise introduction of the A1 mini, a low-cost device that carries forward much of their learnings and technology from their higher priced models.

The A1 mini is targeted at consumers and hobbyists, and is perhaps the most interesting desktop 3D printer we’ve tested in many years.

Bambu Lab A1 mini Specifications and Features

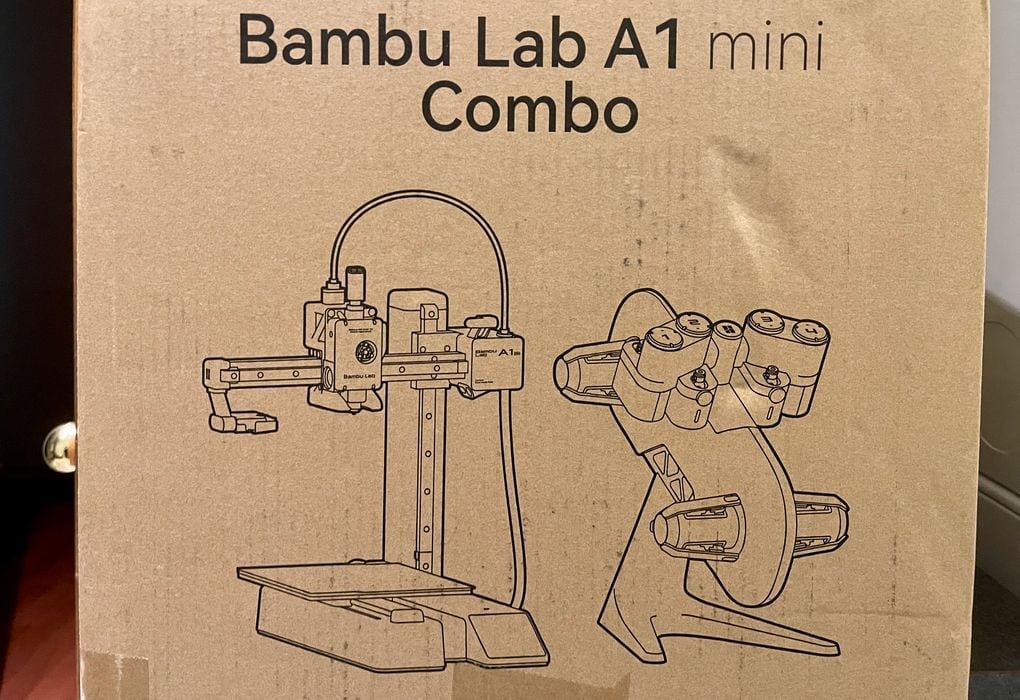

The A1 mini is an open gantry i3-style affair similar to many inexpensive desktop 3D printers, but it has a somewhat smallish build volume of only 180 x 180 x 180 mm.

For extrusion, there is a single nozzle, with a 1.75mm direct filament extruder. The toolhead is all-metal, and can be heated up to 300C.

The build plate is a magnetically attached spring steel plate with textured PEI coating, although a smooth plate is an optional accessory. This surface can be heated to 80C.

All of the above means the A1 mini can support PLA, PETG, TPU and PVA — but unfortunately not ABS, ASA, PA, PC, composite materials and even PET.

The A1 mini includes filament-out detection, power loss and recovery procedures, and can print at up to 500mm/s.

So far this sounds like a somewhat basic desktop 3D printer, but the A1 mini includes an enormous number of advanced features:

- Color touchscreen with easy user interface

- Filament odometer

- Filament tangle sensor

- Vibration compensation

- Motor noise canceling (!)

- Completely automated calibration

- Flow rate compensation

- Cloud interface to Bambu Lab’s MakerWorld

- Webcam — with privacy cover

- Linear rails

- Filament detection via RFID

- Real time monitoring and control

- Quick swap nozzles

- Nozzle pressure sensor

If that wasn’t all, the system also is available with an optional Automated Material System (AMS), which can hold up to four spools of different materials. The AMS swaps filaments as required during the job, and is similarly “sensored” as the base unit.

Bambu Lab A1 mini Unboxing

I was quite excited to get started with this machine, and I wasn’t disappointed.

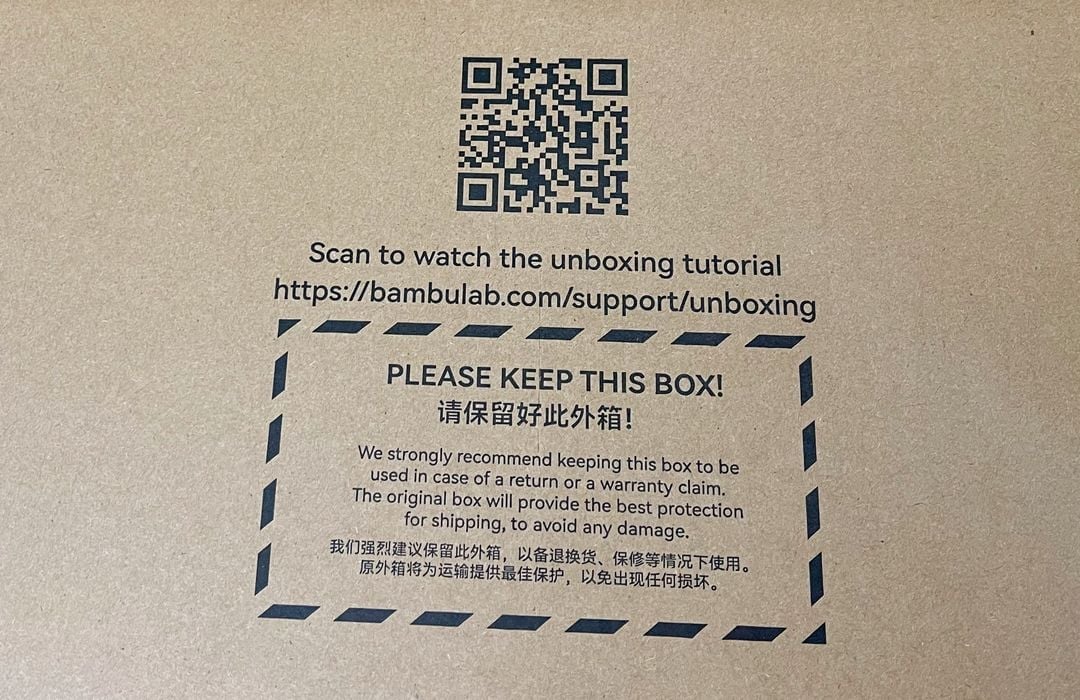

One of the first things you will see is a very friendly mark on the box, with a QR code to get the instructions. I haven’t seen this on other desktop 3D printers, and it’s a very good idea.

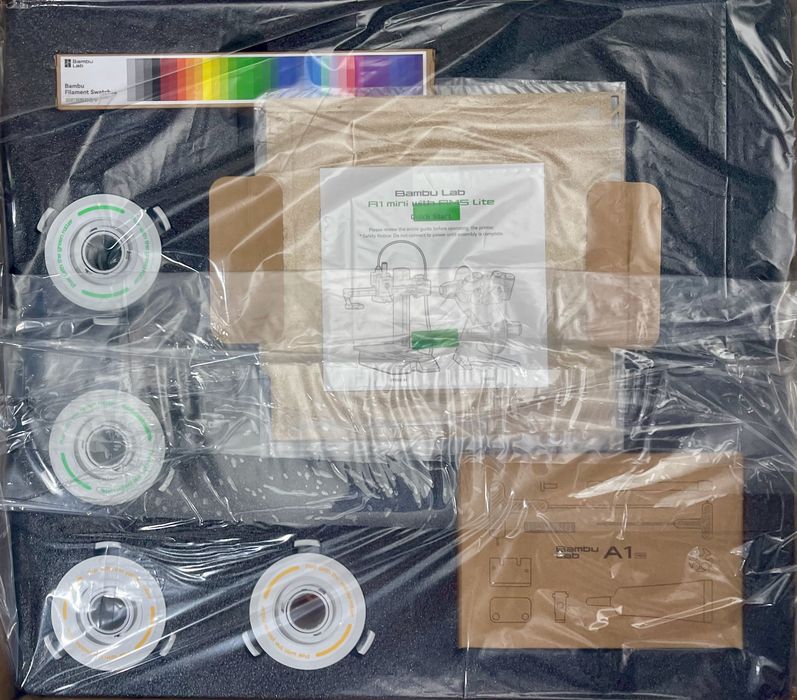

The A1 mini is packaged extremely well, and all was received undamaged. Black form-fitting foam surrounds all parts, yet there were few ties to unwrap. Bambu Lab makes the foam do the work here, and it’s very impressive.

Here’s a closer look at how the main equipment is packaged, and you can see how they brilliantly tie it all together with minimal straps and a lot of foam.

Once everything was unboxed, I was left with these parts. The A1 mini is basically assembled, with very little to do, as you will see.

This was quite interesting: the bolts are separated into bags for each purpose and suitably labeled. There’s no way to get these confused, and I wish other manufacturers would take this step.

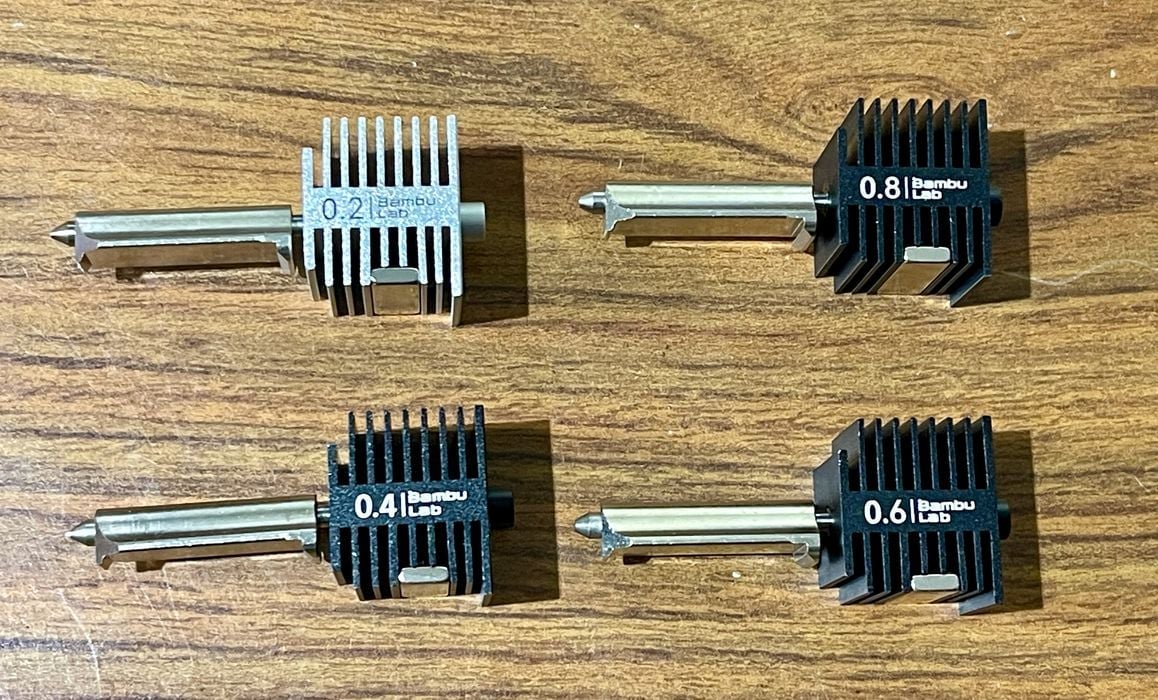

Our shipment included a set of optional nozzles. We received another 0.4mm nozzle, as well as 0.2, 0.6 and 0.8 mm nozzles. I’m not sure why some are black and some are silver.

Every decent 3D printer includes a nice toolbox, and Bambu Lab did not disappoint here.

The Tools are laid out in a way that can easily be replaced after use.

Also included in the shipment was a swatch of filament samples. Bambu Lab also produces quite an extensive line of filament products, along with subscription services for them. This is their way of showing purchasers the materials they can order for their 3D printer. Note, however, that you don’t have to use Bambu Lab materials, it’s easily possible to use compatible third party materials.

A surprise gift box was included. Apparently there are several different gifts, and one is randomly selected for each shipment. The box contains non-printable parts for some type of printing project that we’ll get into a bit later. I found the “Marble Run” project in my shipment.

This is part one of a four part series, please read parts two, three and four.

Via Bambu Lab