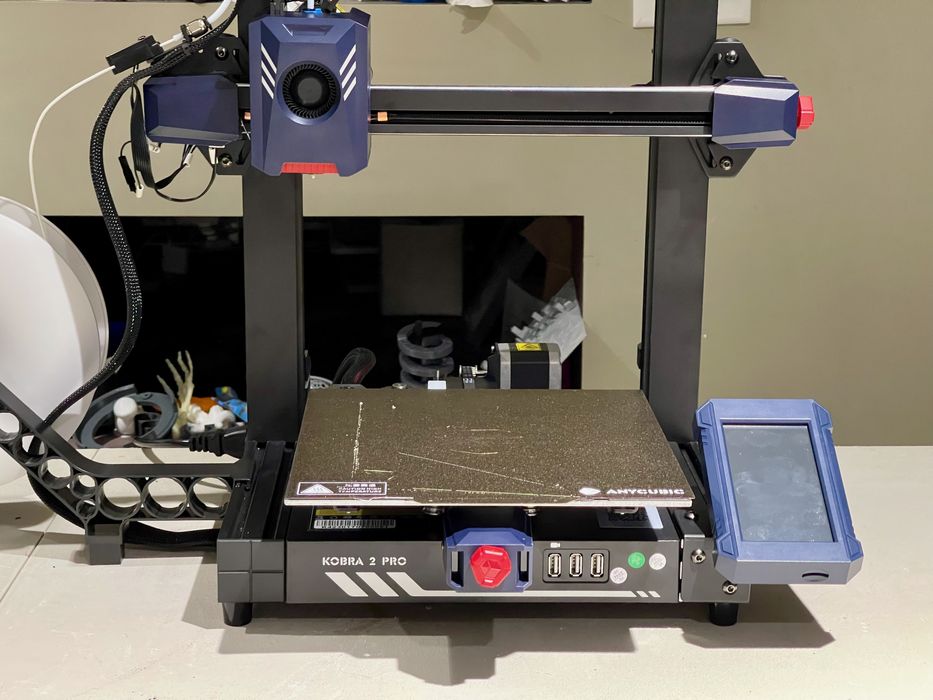

Our hands on review of the Anycubic Kobra 2 Pro 3D printer concludes with Software, Print Results and Final Thoughts.

This is part three of a three part series, please read parts one and two.

Anycubic Kobra 2 Pro Software

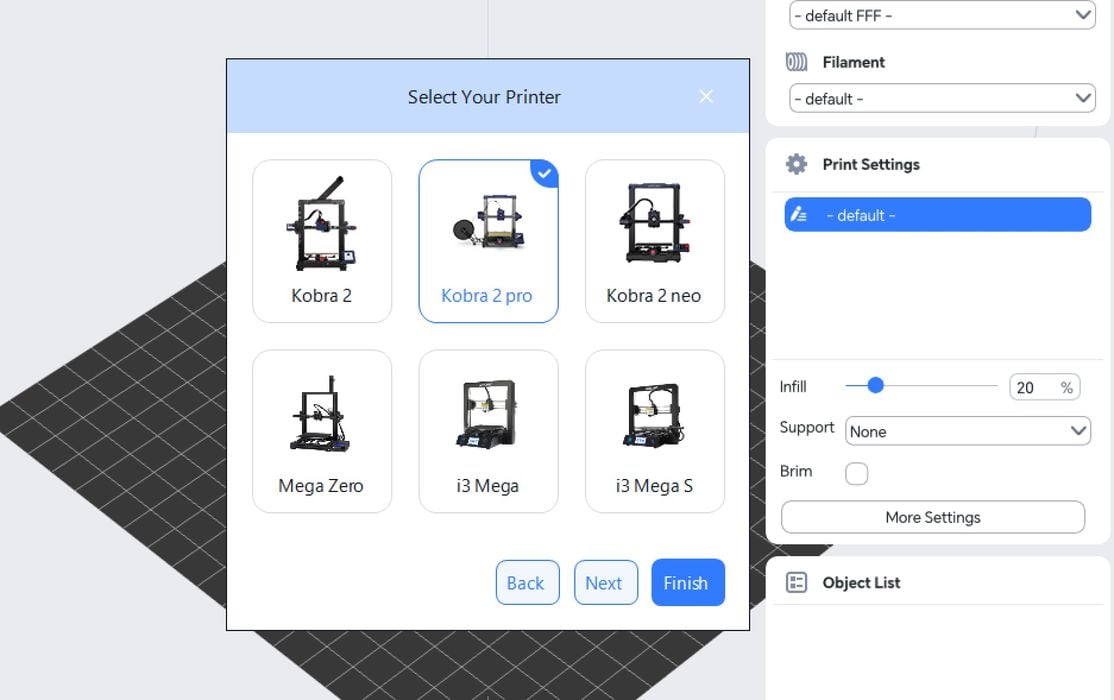

Anycubic provides their own slicing tool with the Kobra 2 Pro, Anycubic Slicer. This is available online for Windows or Mac OS and can be downloaded from Anycubic. The current online downloadable does not support the Kobra 2 Pro yet.

However, the Windows version supplied with the machine, 1.11, did support the Kobra 2 Pro.

You can also PrusaSlicer for job preparation, which is what I used. Many people are quite familiar with that software, so that’s likely where the majority of the use will be. I found a copy of PrusaSlicer 2.6.0 (Windows only) on the stick and an importable print profile, although one should always consider getting the most recent version from the source site.

I tested only with PrusaSlicer, since I saw no advantage in using Anycubic’s slicer.

As is the usual pattern, the issue with software is print profiles. Anycubic supplied a print profile for their High Speed PLA, but no profiles for any other materials. To perform testing of other materials I had to create my own print settings and experiment.

It seems that print profiles are an often forgotten element of inexpensive 3D printers, and I believe that machines would be far more usable if clear print profiles were set up with the machine for immediate use. If I had intended on printing only ABS, for example, I would have had to do filament calibration before I could do any work.

Anycubic Kobra 2 Pro Print Results

The print results from the Kobra 2 Pro were phenomenal, which is saying something because the print speeds were quite rapid. In fact, the quality of the prints exceeded many of my slower speed printers, but completed in less than half the time or better.

Anycubic provided GCODE for a pre-sliced #3DBenchy that actually completed in only 15 minutes. Less, actually. It’s by no means perfect, but I’ve seen worse. This is quite amazing for a low cost machine and shows what it can do.

However, using their standard print profile I was only able to slice this model to a minimum of 23 minutes. I could not persuade the slicer to get it down to 15 minutes. In other words, there is another secret print profile somewhere that Anycubic used to get this fast print.

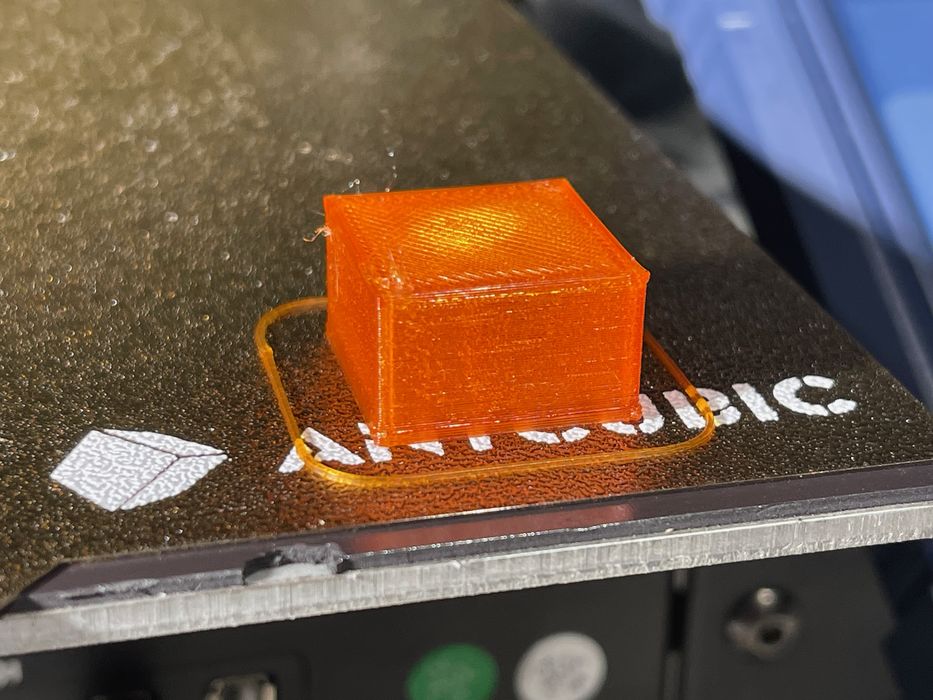

I tried various speed experiments. Here I tweaked the stock profile to run at 500mm/s for laughs, and to my surprise the machine actually completed the #3DBenchy! The quality was somewhat less than the stock 300mm/s profile, but it showed that the machine can indeed run at those extreme speeds with the right material.

Here I compare two prints, with the left being at 300mm/s and the right at 500mm/s. The quality isn’t perfect, but it’s plenty good for many 3D prints.

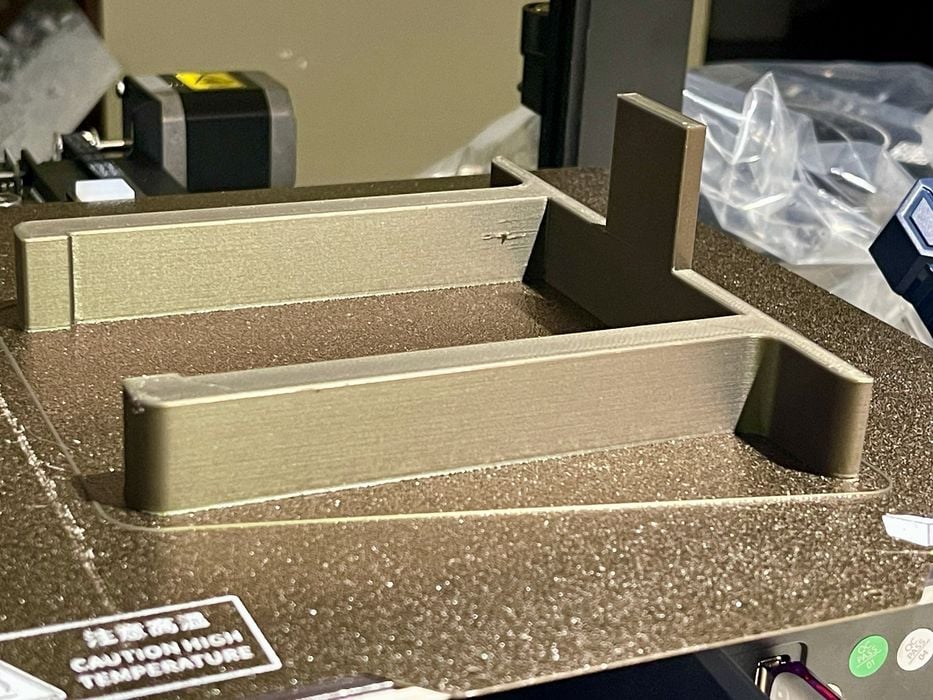

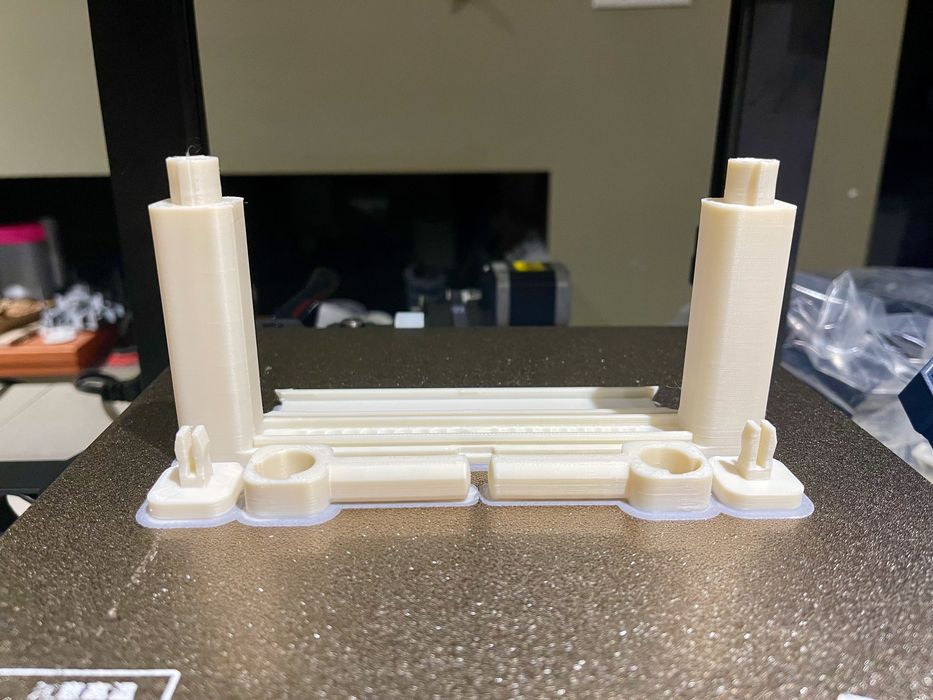

I was able to print some larger items on the Kobra 2 Pro quite easily. The higher speeds allow them to be finished far earlier than you’d expect. This model was done in only 85 minutes!

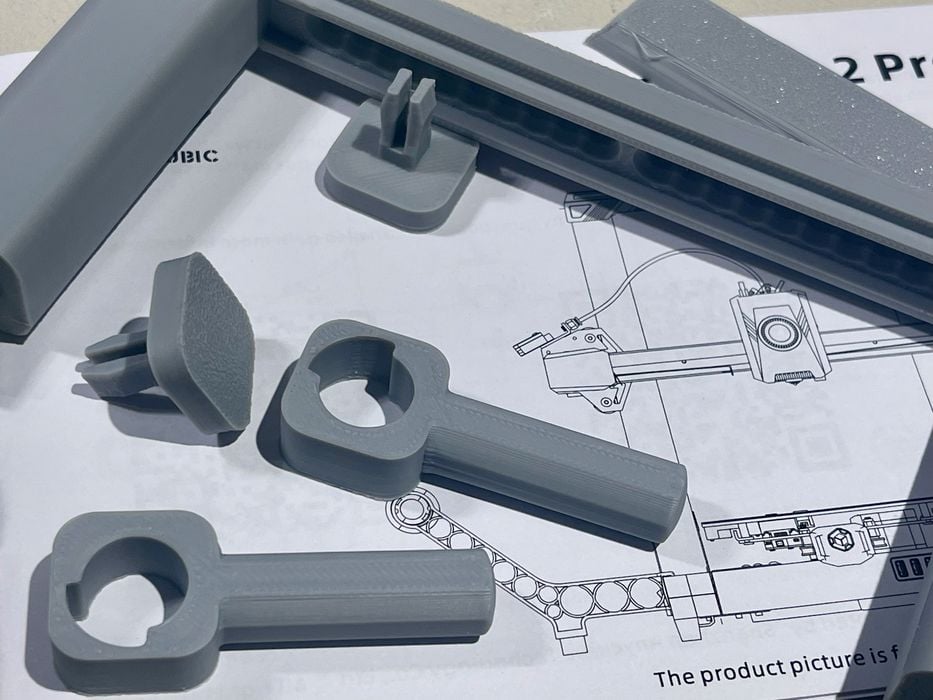

What continually astounded me was the quality of the results at these rapid print speeds. Here we see some parts printed and they’re basically perfect. I observed no ringing at all on any prints, suggesting that the vibration compensation works just fine.

Moving on to other materials, I tried ASA (which is nearly identical to ABS). This print worked very well, and had the same quality as PLA prints. Of most interest was that the print speed was quite fast: 300mm/s. This means that the Kobra 2 Pro can competently print ABS materials at high speeds. This is important because the longer an ABS print takes, the more it can warp. Here I saw no warping at all, one of the best ABS prints I’ve ever made — on an open air machine, no less.

I attempted PETG and it also worked very well at high speeds (300mm/s). Note that neither the ASA nor PETG were designated as “high speed” filaments.

Finally, I attempted to print in TPU, with no expectations that it would work at high speed.

It worked and it didn’t work. My first attempt was with Fiberlogy’s 40D material, which is quite flexible. I couldn’t even load it into the Kobra 2 Pro, as the load sequence was simply too fast for this material. It wrapped around the gears and took me half an hour to get it out.

I had better results with a spool of slightly less flexible material. It managed to load and I was able to print it easily — but only at a speed of 20mm/s.

I’m hoping to find a source for “high speed flexible” material to give that a test, but I suspect there’s little hope of 300mm/s for that kind of material.

I should add that all of these materials adhered properly to the print plate. They were relatively easy to peel off after printing. This may have something to do with the LeviQ 2.0 Z-gap setting, but whatever it is, it works really well.

Anycubic Kobra 2 Pro Final Thoughts

I was extremely impressed with the Kobra 2 Pro 3D printer. It’s fairly easy to build, and has almost completely automated calibration. The machine is fully capable of extremely high speed 3D printing, given the right kind of materials.

There are a number of advanced features that seem set up on the machine but not yet available, so the future looks bright for this machine.

On the downside, the most frustrating part for me was the lack of broad print profiles to enable more variety in 3D print materials.

Nevertheless, for a machine that’s currently listed for only US$279, it’s a complete steal.

ANYCUBIC

KOBRA 2 PRO 3D PRINTER

★ BEGINNER 8/10

★ ENTHUSIAST 9/10

★ PRODUCTION 9/10

BEST FEATURES

✔︎ Very high speed printing

✔︎ Perfect calibration

✔︎ Inexpensive

QUESTIONS

✖︎ Print profiles

✖︎ Y-axis loose

✖︎ Cable labeling

This is part three of a three part series, please read parts one and two.