We gave the new Anycubic Airpure a test in our lab.

One of the most unpleasant aspects of operating a resin 3D printer is that almost all photopolymer resins emit noxious odors. Some people are directly affected by these odors, while physical contact with the resin can be toxic.

To counteract this effect, some advanced resin 3D printers include a filtration system that draws air from inside the machine through HEPA and activated carbon filters before exhausting to the surrounding air. Usually that approach helps a lot, but there are very few affordable desktop resin 3D printers that include that feature.

Some resin 3D printer operators use an external ventilation system to properly get rid of polluted air by putting it outside. This is the optimal solution, but there are two problems: first, the 3D printer’s room might not have a way to install a ventilation system; and secondly HVAC systems can be expensive, often more than the cost of the printer itself.

Another common solution is to purchase a standalone filtration unit that sits beside the 3D printer. This will accept vented air from the printer and push it through filters before exhausting it. Again, however, these tend to be pricey, particularly for those using inexpensive desktop resin 3D printers.

Enter Anycubic’s AirPure device, a specialized air filtration system designed for use with resin 3D printers.

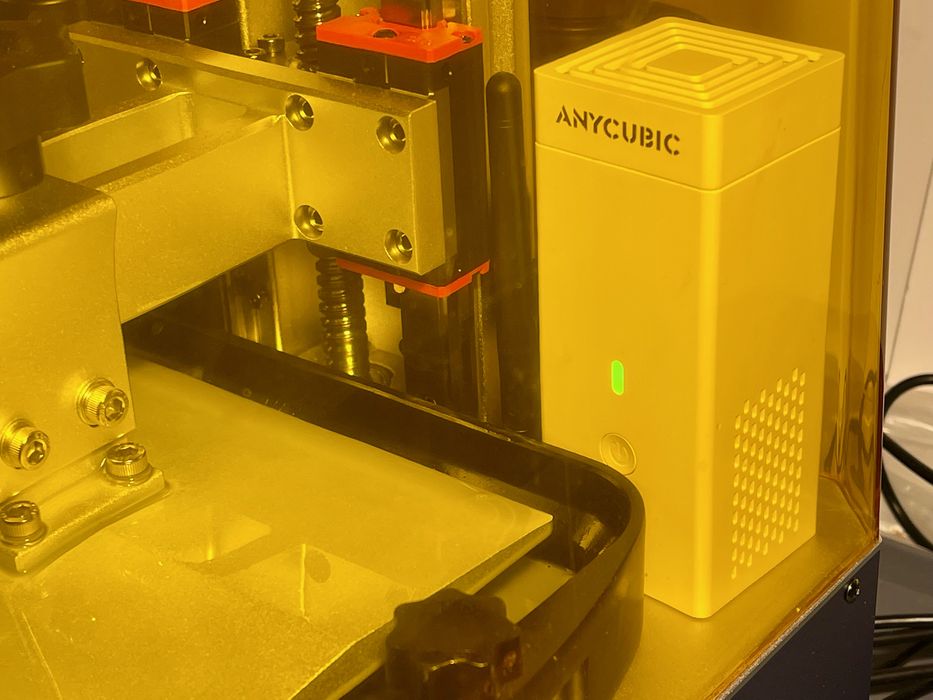

It’s a small, battery-powered device that’s about the size of a standard drink can. This unit pulls air from the sides and through internal carbon filters, finally exhausting at the top.

To install the AirPure, you must place it inside the build chamber under the UV cover. There should be space to fit the small unit on most machines, but in my case I was testing with an Anycubic M3 Plus, equipped with a pump resin refill system and a camera stand, leaving no room for the AirPure. I opted to take out the camera, which left plenty of room.

Operating the AirPure is straightforward: you just push the only button and a green light comes on. The AirPure is almost silent and the airflow isn’t particularly strong.

Replace the UV, and then begin printing. As the resin emits particles, the idea is that the AirPure will catch them before they leak out and cause odors in the printer’s vicinity.

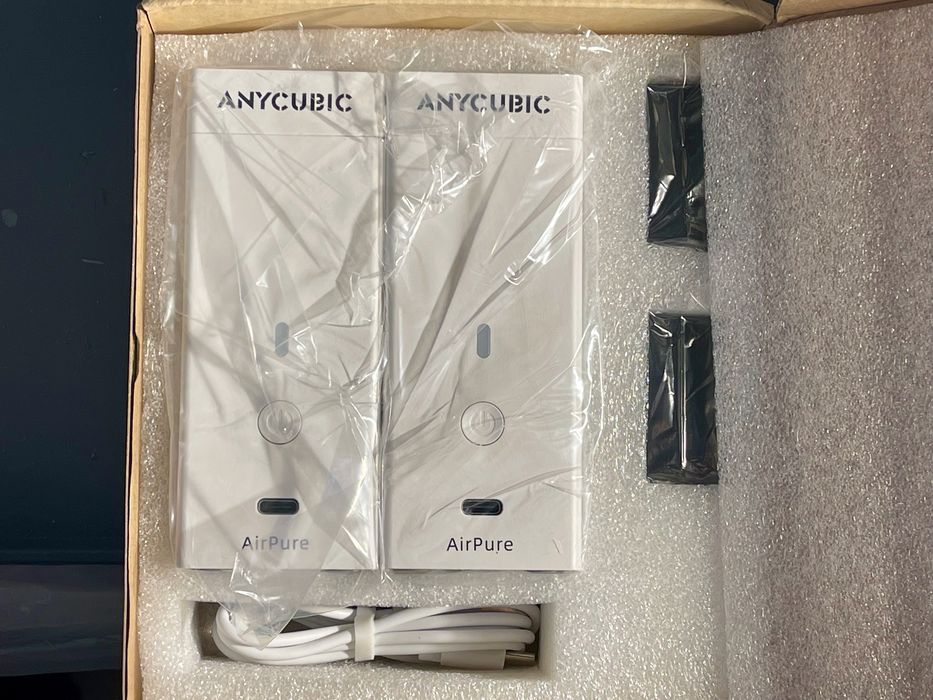

To set up the AirPure, you should first recharge the batteries with the provided USB-C charging cable. Then you must open up the top and insert a carbon filter, and replace the lid. The AirPure is then ready for action.

Does it work? I gave the AirPure a test by turning off my normal external ventilation system and running a job on the printer. While I don’t have any sophisticated particle measurement sniffers, my nose did note a decrease in odor that would normally be expected.

To be clear, I did still smell a slight resin odor if close to the machine, but this was definitely less than it would have been without the AirPure.

My thought is that the AirPure was competing with my 3D printer’s fan system, which is used to keep the light engine cool on longer jobs. These fans were far more powerful than the AirPure, so it’s not surprising that some odors leaked through.

My suspicion is that the AirPure would work even better on resin 3D printers that don’t have a fan system, and many do not.

The AirPure can also be used for FFF 3D printers, but only if the device has an enclosure, otherwise fumes would escape the AirPure.

The filters in the AirPure can be swapped when necessary, but only one is shipped per AirPure unit. Additional filters must be obtained from Anycubic. Oh, and remember to turn off the AirPure when the print job finishes, otherwise you may run down its battery.

Perhaps the AirPure’s best feature is its price, only US$23 for TWO units. This is literally orders of magnitude lower than big industrial filtration units, and something everyone can afford.

Via Anycubic