I’ve been playing with SuperSlicer for the past week and have some thoughts.

Superslicer is a fork of the popular PrusaSlicer 3D print management system, itself based off the open source Slic3r system. While PrusaSlicer is extraordinarily popular and is frequently updated, one programmer thought up some new features and forked their own version, SuperSlicer. We have more details in our previous story.

As you’ll see in that story, the main claim to fame for SuperSlicer is that it integrates a series of 3D printer calibration features. I am always concerned with calibration, so it gave SuperSlicer’s calibration routines a try.

Calibration is quite important for any FFF 3D printer, even though the manufacturer may claim they’ve done it already from the factory. The truth is that no manufacturer can calibrate an open format 3D printer because they simply don’t know what filament you’ll be using. The print parameters must be determined for each print job to match the material to the machine. This is why some 3D printer manufacturers strongly recommend branded materials through their print profile libraries — they can know exactly what’s happening.

But for most of us that’s not the case. We have a pile of random spools that have to be used, and there are no print profiles. Hence, calibration.

Some may think 3D printer calibration is the act of leveling the bed or printing a #3DBenchy. Those are certainly part of it, but there are many other things to calibrate in order to achieve perfect 3D prints. It’s my belief that most 3D printers, even the least expensive models, can be persuaded to produce great output if they are properly calibrated and maintained. Calibration is important.

Calibration involves setting a series of parameters to adjust machine operation that could affect material flow, adhesion, stringing, and more. Over the years the 3D print community has developed a series of tests that can be used to identify the correct parameter values. One example is the classic Temperature Tower, used to figure out the optimal extrusion temperature.

The problem with all these tests is that there are several of them and it’s hard to find all of them. There is also a proper sequence they should be run, and no one tells you the correct order of operations. Finally, setting up some of these tests is extremely tedious. For example, a temperature tower requires setting up multiple different modifier regions, each with a different temperature. It’s not something you want to do over and over.

Enter SuperSlicer. The software’s new Calibration menu includes automated tests for:

- Bed/Extruder leveling

- Filament Flow

- Filament Temperature

- Extruder Retraction

- Bridge Flow

- Ironing Pattern

- Final Calibration Cube Test

The best part is that each of these tests are automatically generated. By “generated”, I mean a standard 3D model is selected, placed and all test print parameters are set up, including modifier regions. For example, the Filament Temperature test creates a print job with multiple temperature regions, literally at the touch of a button.

Wait, there’s more: most of the tests show visual examples of what’s good and what’s bad. You will know precisely what you’re looking for, and SuperSlicer tells you how to make the adjustments. The only issue I found was some of the print parameters to adjust were hidden in unknown locations. Perhaps Prusa Research could include a search function like that found in Ultimaker Cura?

I went through several of these tests to see what happened, and I was quite surprised.

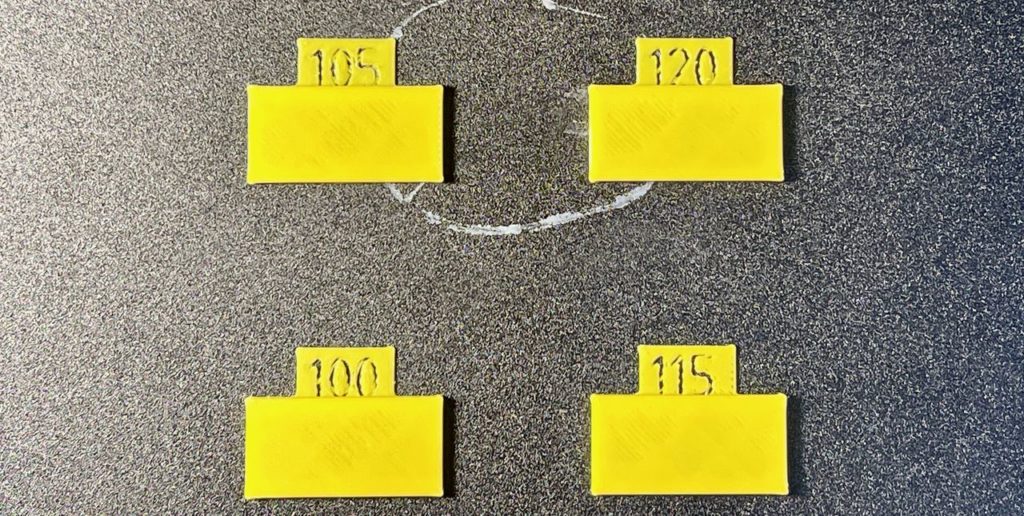

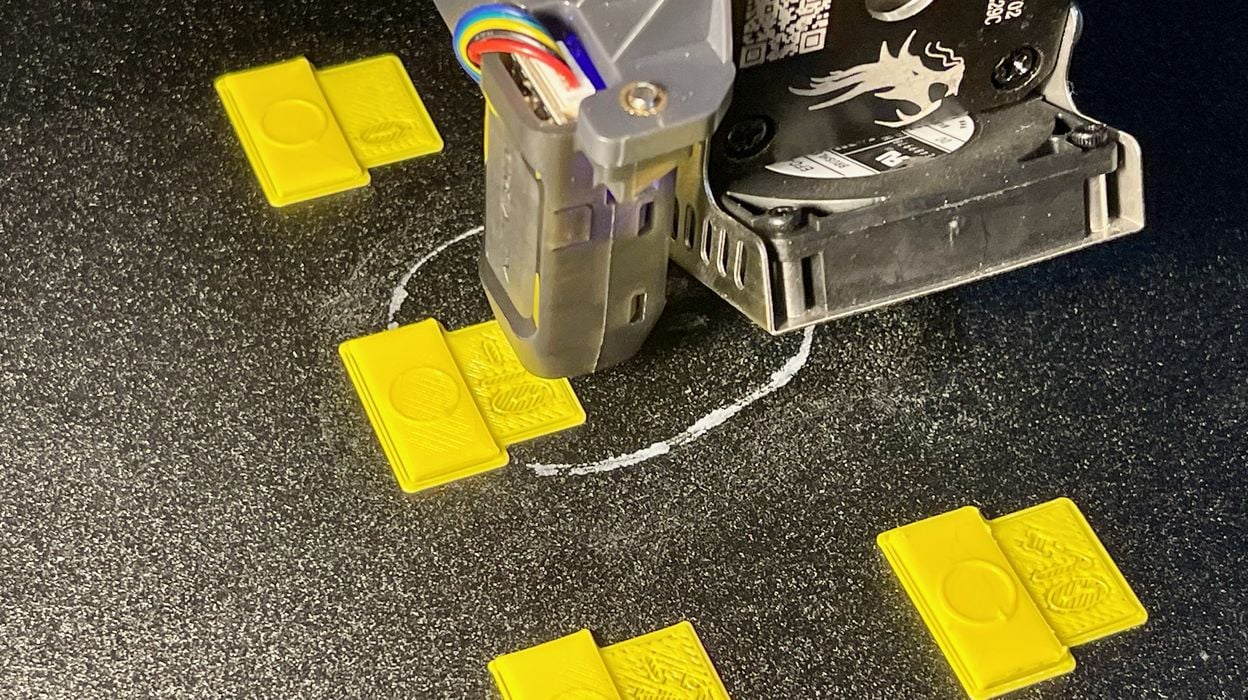

Bed/Extruder leveling

For this test SuperSlicer generates five small one-layer pads that are printed in the corners and center of the bed. There’s small tabs that you can grab to pull them off the bed, quite handy!

My 3D printer’s bed was already leveled, so I didn’t expect much from this. However, I discovered that in fact the bed was tilted and that in one corner in particular. After some manual bed adjustment and a few re-tests, I was able to fully level the bed properly.

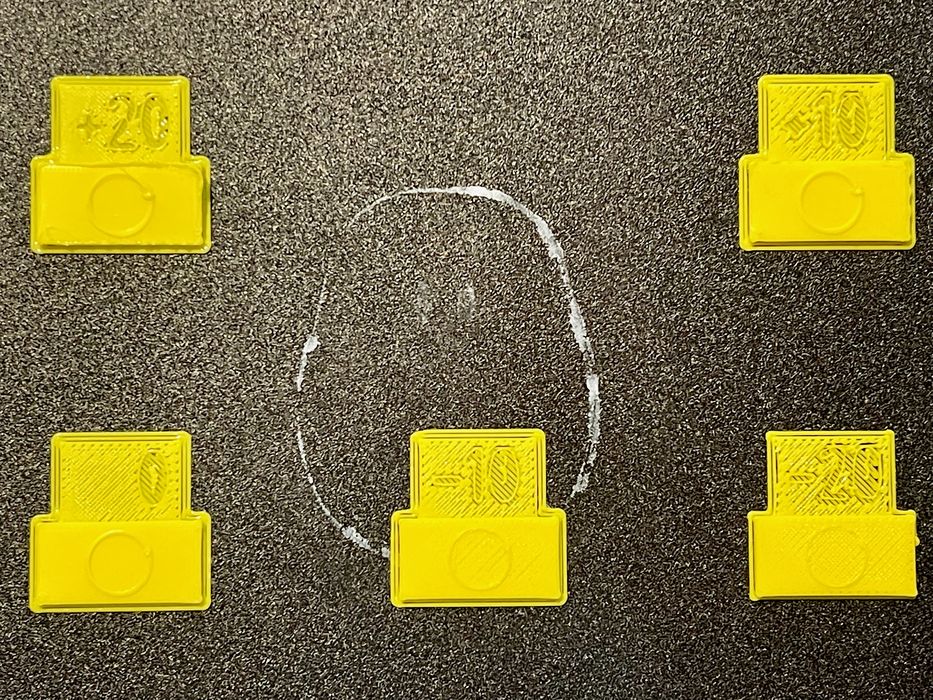

Filament Flow

This test is to figure out the correct extrusion multiplier. Basically if the flow is too low, for example if the filament has a small diameter, then less material will be deposited than expected.

The test prints a series of blocks with different multiplier settings in sequence, and you need only check the quality to pick the right multiplier value.

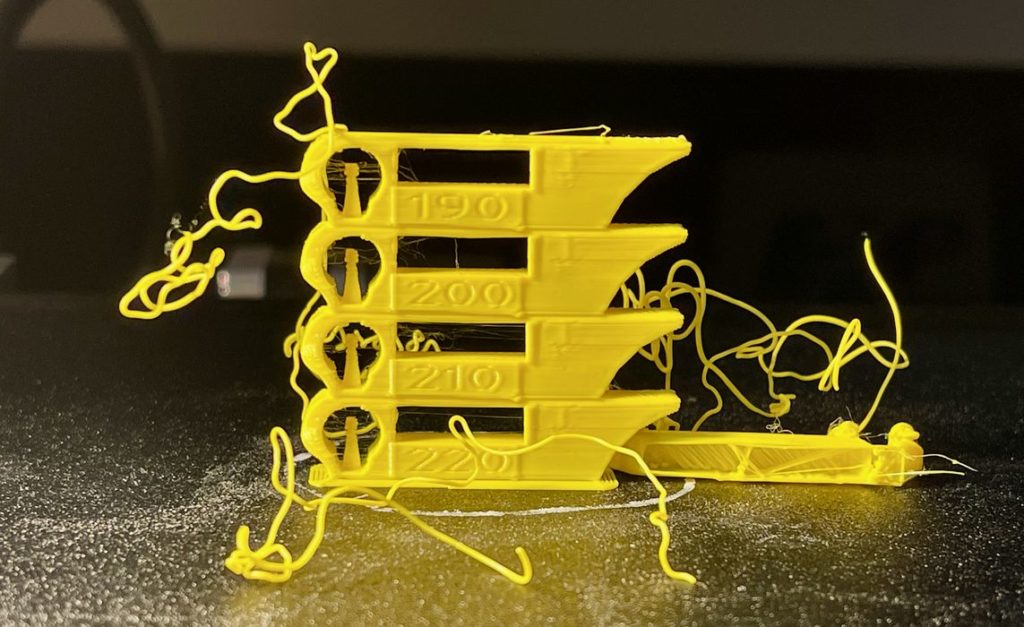

Filament Temperature

Setting up temperature towers is truly a pain, but with SuperSlicer it’s so easy it could be quickly used with any new filament.

I found the ideal temperature for a specific filament on a single run of this test, which was slightly different from the manufacturer’s default setting.

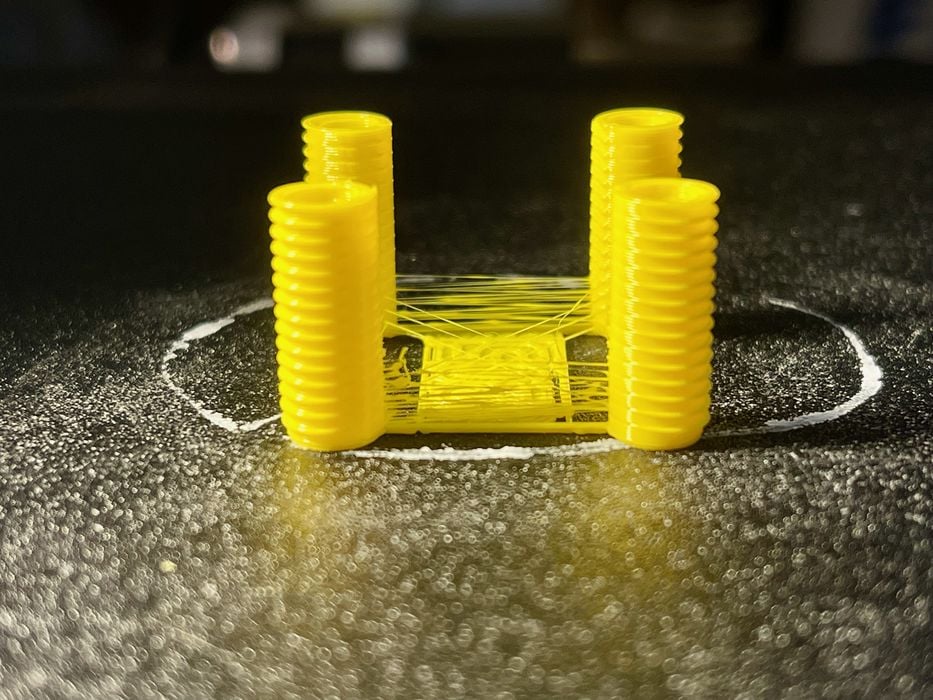

Extruder Retraction

Stringing is the curse of 3D printing, and with this test you can very quickly identify the retraction length. For my test I ended up with 0.5mm, which basically eliminated stringing on subsequent prints.

Bridge Flow

For bridge structures it’s important to get the flow just right. If not you end up with droopy overhangs or worse. This test is a two-part sequence that helps dial in the right parameters for 3D printing this common structure.

Ironing Pattern

Ironing is the process of using the hot nozzle to flatten top surfaces, but different results can occur with the several possible parameters for ironing. Again, the test dials it in. However, in my test the results were inconclusive, so this may be a bit harder to finalize than the other tests.

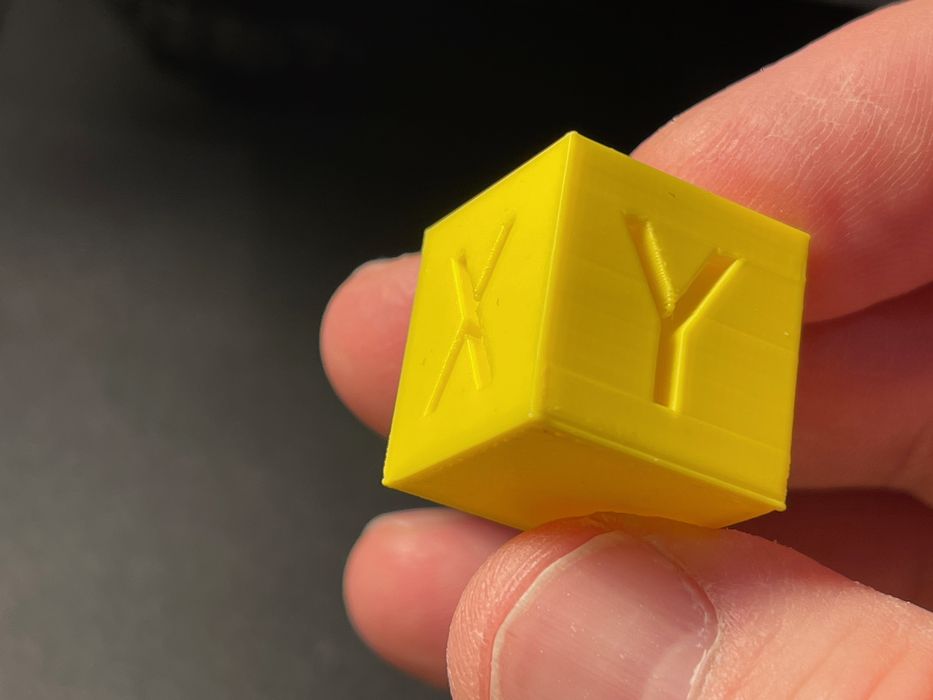

Final Calibration Cube Test

At the end of the test sequence you are requested to print a standard cube in order to ensure the dimensions are accurate. SuperSlicer recommends printing two different cubes and comparing. If the results are off, then you might have to adjust the stepper parameters or other motion system parameters to compensate.

I also printed the CTRL-V test, first with defat settings, and then with the calibrated settings. The results were quite a bit better with the calibrations done, as you can see.

PrusaSlicer vs SuperSlicer

I found the SuperSlicer calibration features so incredibly useful that I believe they, or something like that, should be incorporated directly into PrusaSlicer itself. Since SuperSlicer is open source, this should not be technically challenging.

While PrusaSlicer users could certainly benefit from this, Prusa Research itself could even benefit from the calibrations that would be done: they may lower their support calls as 3D printer operators may “fix” their own issues via proper calibration.

If you’re reading this, Prusa Research, please take a hard look at what SuperSlicer has done.

Via GitHub

If you want the best of both worlds, use Orca Slicer. The developers forked Bambu Studio (which was a fork of PrusaSlicer which was a fork of Slic3r) and are pulling in tons of features every week from Superslicer, Bambu Studio, and Prusaslicer. Check it out. https://github.com/SoftFever/OrcaSlicer/