We complete our review of Simplify3D V5.0 with a look at previews, features, bugs and final thoughts.

This is part two of a two part series, please read part one.

Build Previews In Simplify3D

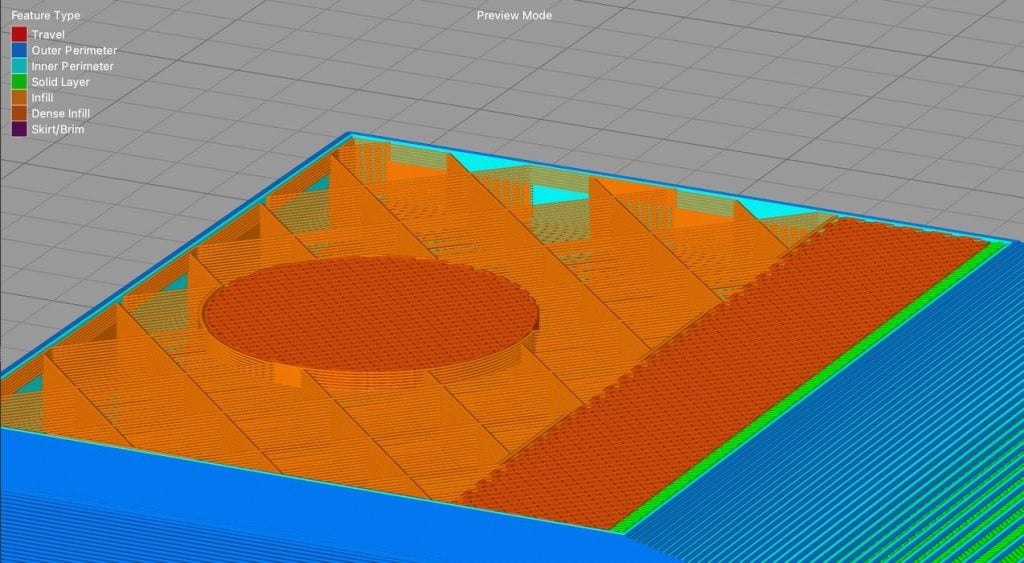

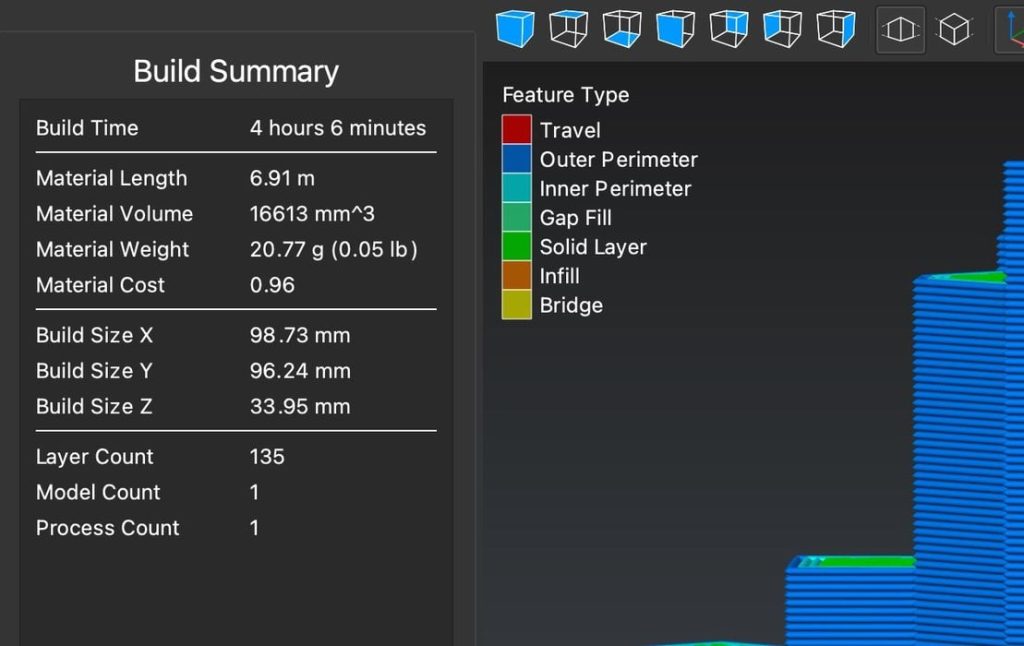

The preview function in Simplify3D V5.0 is stunning. Not only do you get a full, spinnable 3D view of the build, but you easily can zoom in precisely to see exactly what will take place in the print job.

What’s really interesting is the way Simplify3D has designed the visuals through the use of colors. There are several ways to display the preview:

- Movement Speed

- Layer Height

- Feature Type

- Active Toolhead

- Current Process

I found these displays very engaging and extremely easy to recognize issues right away. Many slicing programs I’ve used recently seem to have big trouble with this aspect, and I’m often shown 3D views that are really hard to visually interpret. Not so with Simplify3D V5.0.

One really useful feature is that they seem to have figured out how to compute print times pretty accurately. Lately I’ve seen estimates all over the map with different tools, but from the testing I’ve done with Simplify3D V5.0, the print time estimates are pretty close.

Simplify3D V5.0 Functions

here are apparently 120ish improvements and additions to V5.0, but I have yet to see a complete list of them. Nevertheless, Simplify3D has described several new features and changes that I wanted to try out.

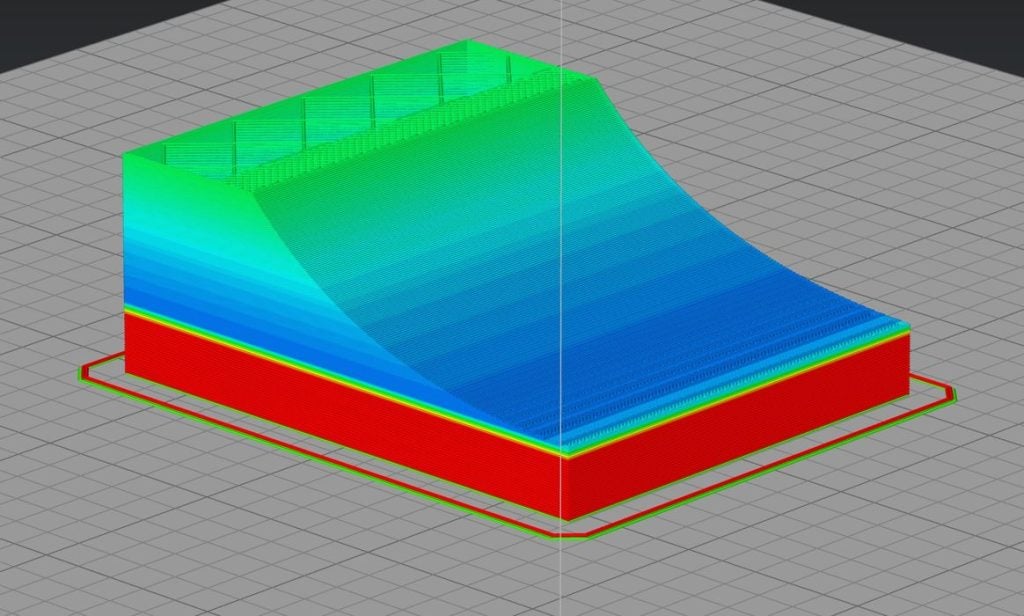

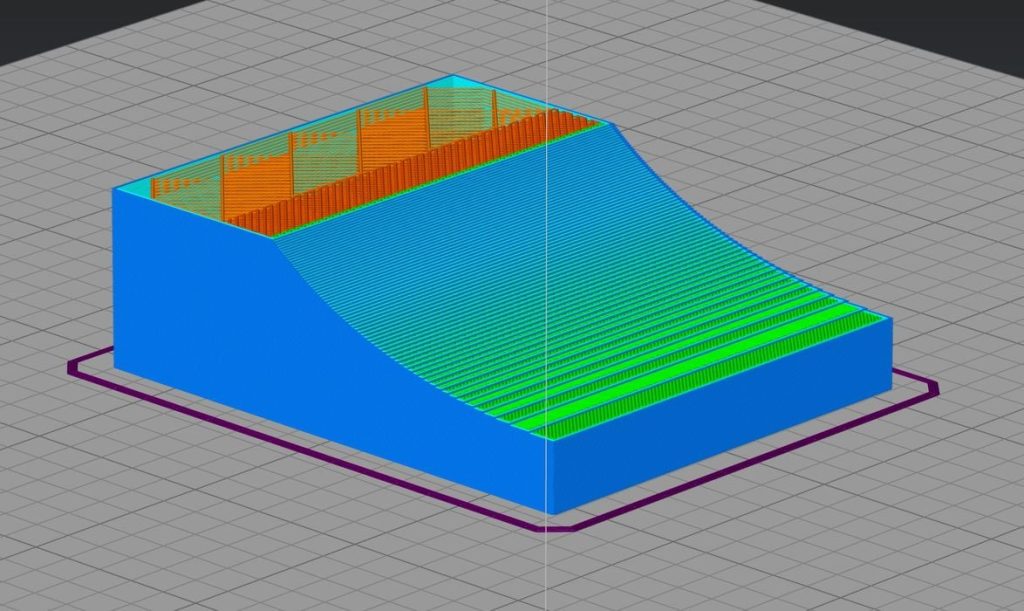

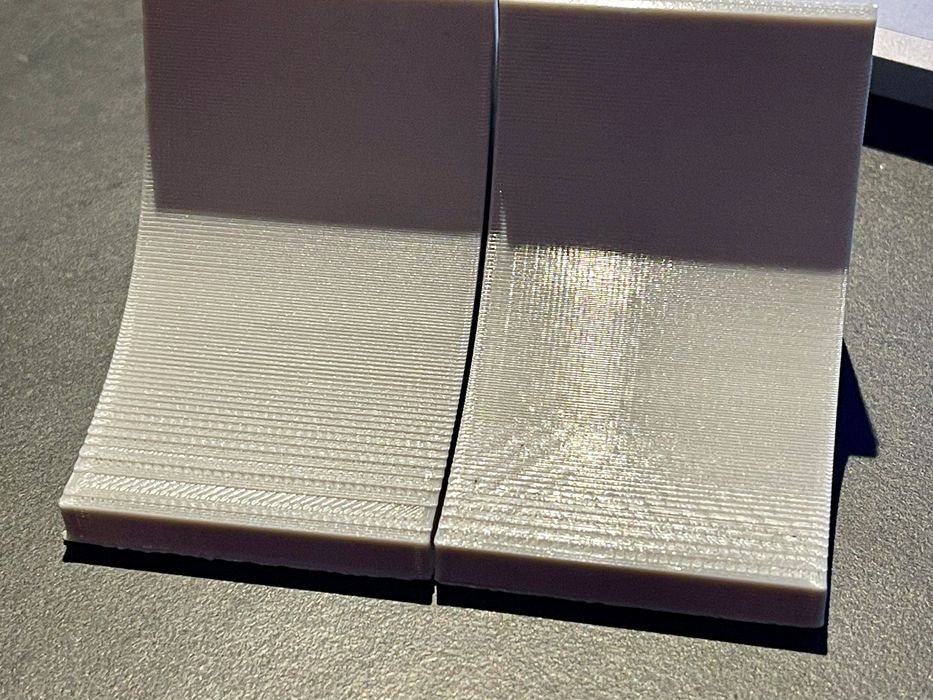

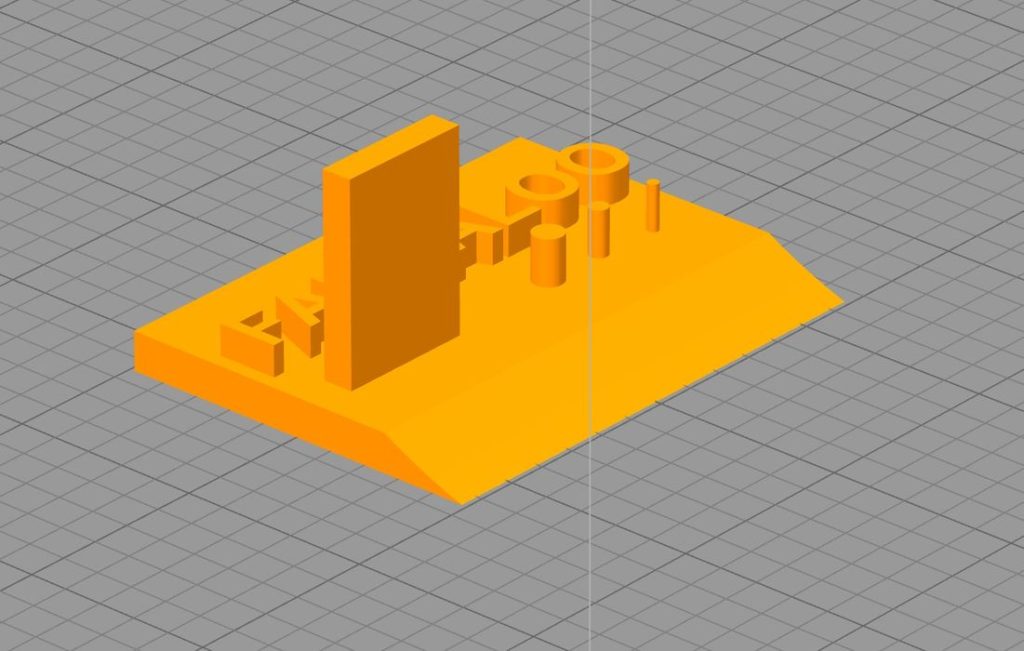

The one I like the most is the adaptive layer heights. Basically, if the software detects a very gradual slope in the geometry, it automatically adjusts the layer height to be a lot thinner to avoid the “stair-stepping” effect you see on angled surfaces. Alternatively, if the surfaces are mostly vertical, it can up the layer height to speed the print.

Here you see a view of the layer height in a model that had them dynamically adjusted. You can clearly see there’s a lot going on here, with many layers changed.

The results are pretty good. I created a cooked-up 3D model to test this, and you can clearly see the difference in print quality between the automatic and standard layer height prints. This is a feature that should probably just be left on all the time. Note that using this feature may add some duration to your 3D print job, depending on the geometry.

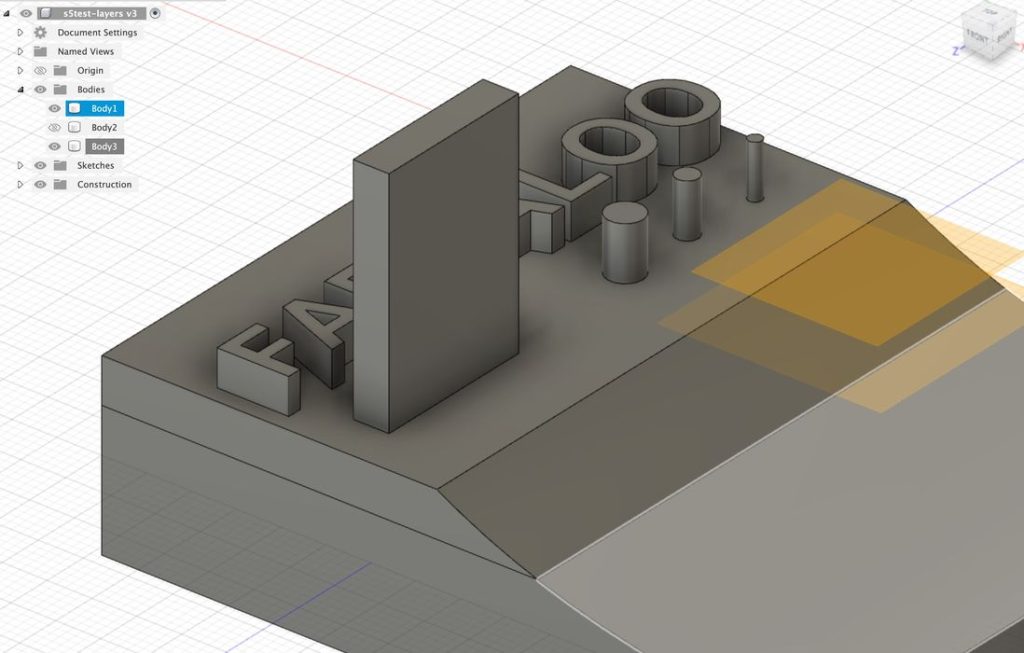

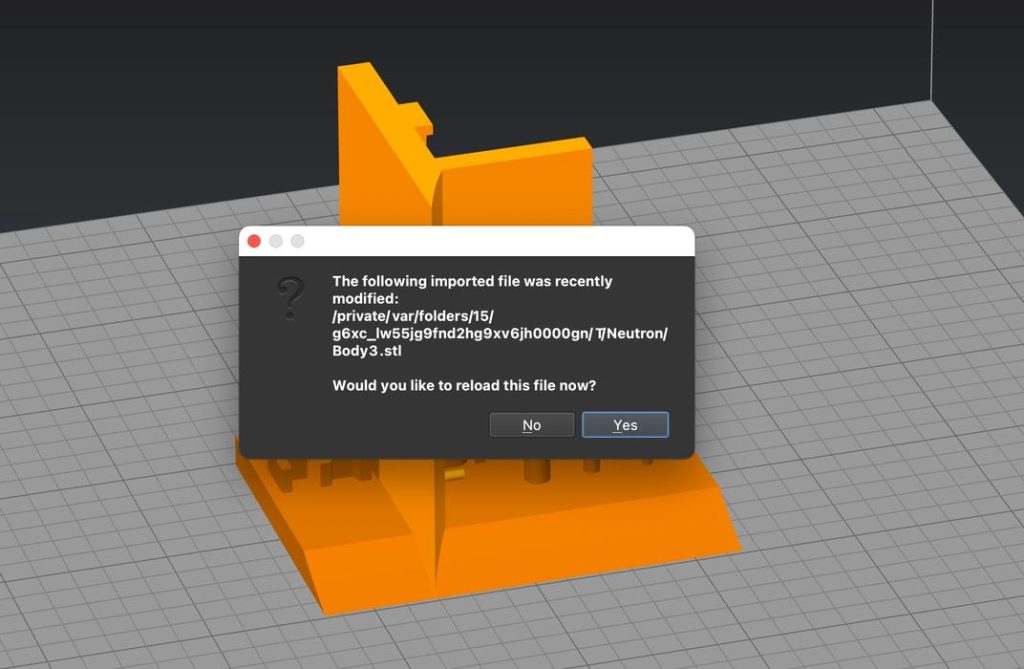

A new feature in Simplify3D V5.0 is direct CAD integration. I wasn’t quite sure how this worked, but I figured it out. Here’s how it works:

- Develop a 3D model in a CAD tool (I used Autodesk Fusion 360)

- Export the mesh (in Fusion 360, this is “Save as Mesh”)

- In the Fusion 360 output target, select “Simplify3D” as the application

- The model suddenly appears in the build window of Simplify3D

- Make adjustments to sizing, orientation, supports, etc., as you’d normally do in Simplify3D

- Go back to the CAD program and change something in the geometry, like adding a feature

- Export the altered CAD model as before

- In Simplify3D the updated model appears, but it asks you if you want to renew it

- If you confirm, the new geometry has all the setup activity re-applied to it automatically

- You then continue prepping the print job

This is quite ideal because it solves the situation where you only discover a geometry problem when painstakingly setting up the print job. Without this feature you’d have to redo all the setup from scratch, so this could be a massive time saver for some people.

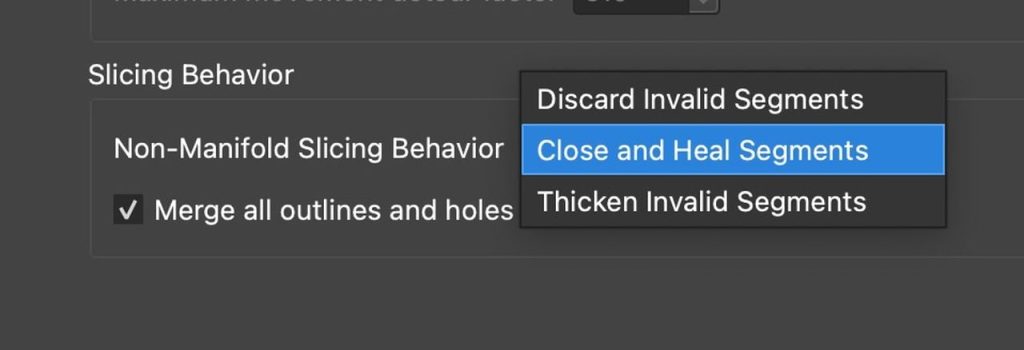

Simplify3D said they’ve improved the 3D model repair tool significantly. Often STL models are missing faces or other structures, and require repair.

While some slicers don’t do anything, Simplify3D has a repair function that’s apparently been improved in V5.0. I gave it a test with a pathological model.

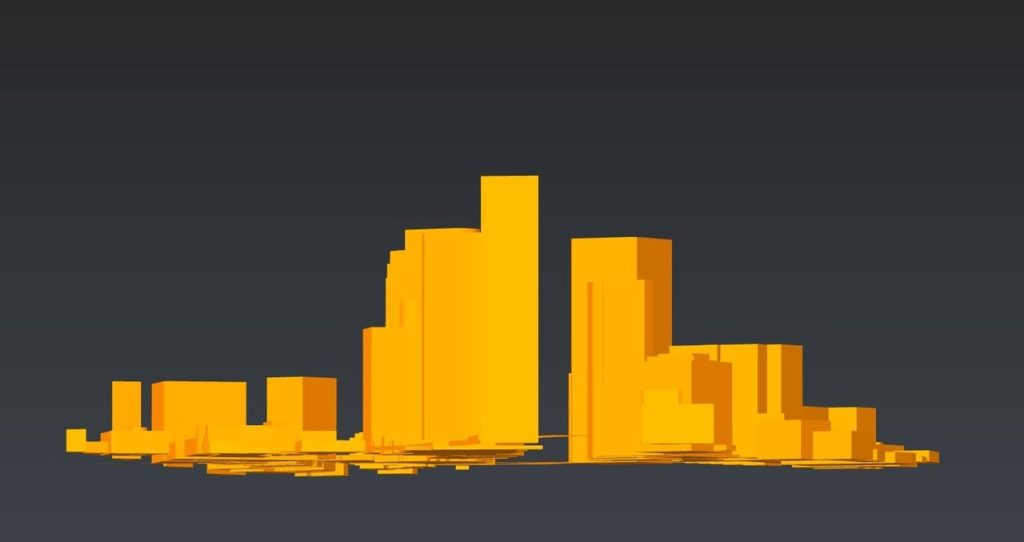

My test involved a cityscape 3D model obtained from Citymapper. The buildings are solid, but the “ground” is a 2D surface. I wondered what Simplify3D V5.0 would do with this.

It turns out it treated the surface as a one-layer structure, and sliced it appropriately. This might actually print, had I decided to add some support structures. I’ll be testing this against other messed up 3D models when I encounter them.

One feature I was looking for was the Arachne dynamic flow control feature that was recently added to both Ultimaker Cura and PrusaSlicer. This feature allows the slicer to fatten or thin the extrusion line to match what’s needed in complex infill scenarios. It makes for far better parts.

Unfortunately, I could not find any mention of Arachne in Simplify3D. However, when I asked Simplify3D about it, it turns out they already had a similar feature, all the way back to version 4.1 that I didn’t even know about. The features are called Variable Extrusion Sizing and Dynamic Gap Fill, and you can find out more about them here. The defaults allow extrusions to vary between 50% and 200% of normal extrusion width.

Simplify3D V5.0 Problems

One thing I’d really like to see in a future version of Simplify3D is some kind of calibration aid, such as appears in SuperSlicer. Basically it’s a wizard that gets you to print a series of easy models to determine the best print parameters. It’s basically foolproof and could add a great deal of value to Simplify3D.

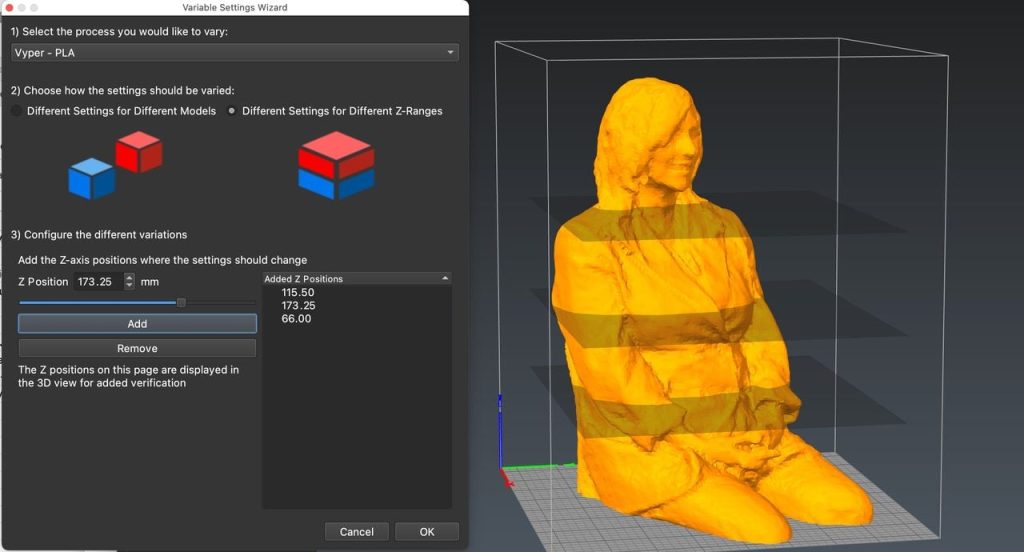

One issue that did actually crash the software is when I tried the new Variable Settings Wizard. This allows you to set up “zones” in the print to which different print parameters (processes) could be applied. This is often done if you need, say, a beefy base, but a spindly top.

While I could set up the zones properly by adding planes to define the zones, when I hit the button to complete the process and create processes for each zone, the software crashed, and would do so every time. This is a bug that should be fixed by Simplify3D. Simplify3D contacted me and it seems there is some kind of bug in the software that is encountered only in the latest version of MacOS, where I happen to be running V5.0. It sounds like they’re on it, and a fix should appear shortly.

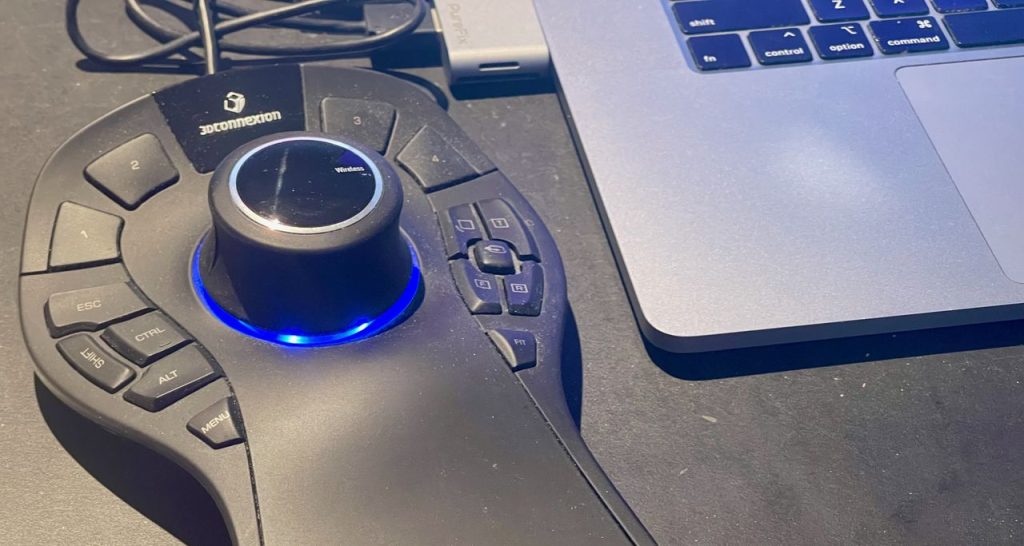

A new feature is the ability to use a 3D mouse, the most popular of which come from 3DConnexion. If you’ve not tried these devices, they is something you will become addicted to once you try them. The 3D mouse allows you to easily swoop around the model, viewing it from any angle almost instantly.

Unfortunately, I could not get this to work on my configuration in spite of the 3D mouse working on other applications. Simplify3D said that it is definitely known to work on other configurations, and I’m hoping I can get this feature working. If you’ve ever used a 3DConnexion mouse, you will know they are a bit flaky to get going on new software, but once set up, work very well.

Nevertheless, that is just a bug that will no doubt get fixed. With the initial release of this V5.0 software, I have no doubt users are going to find lots of bugs for Simplify3D to fix, although some users might want to wait until the next minor release. Perhaps Simplify3D should have done a public beta test first to find and destroy those bugs?

Getting Simplify3D

Unlike some other 3D print slicing software, Simplify3D is a paid product available from an independent company that does not produce anything else.

The current price for Simplify3D V5.0 is US$199 for those not owning a prior version of the product. For upgrades, Simplify3D provides a discounted price for those with older versions, and a free upgrade to V5.0 for those who purchased V4.1 within the past year.

Current customers of Simplify3D need only go to the license management page on their Simplify3D account to see all the options, purchase and download V5.0.

Some Simplify3D users have very comprehensive sets of settings and profiles they’ve built over the course of years in V4.1, which they no doubt want to keep using. For this, Simplify3D V5.0 does not overwrite anything and stores all that stuff separately. To migrate, V4.1 users simply export all their profiles and then import them into V5.0.

Simplify3D V5.0 Final Thoughts

After such a long wait, it’s natural to expect V5.0 to include “years” of improvements, and users expect a lot. There are indeed many dozens of feature improvements in V5.0, with improved displays, functions and print quality.

The system is easy to use and I found that after some time using V5.0, it felt very “solid” in the interface. There are tons of powerful features available, far more than I will likely ever use. However, for those with unusual or advanced FFF equipment, Simplify3D V5.0 will be very important. I enjoy using it and will continue to do so.

One may ask why there is a need to pay for a slicer when several very good options are available for free. In fact, the price of some of the more inexpensive desktop 3D printers are now the same or even lower than the price of Simplify3D!

My thinking is that Simplify3D is not necessarily a tool for everyone with a 3D printer. Those operating basic setups might be served well by free options, and those tools match the budget.

However, those using advanced equipment, requiring the best possible slice options for production parts, advanced support structure management and more could benefit from using Simplify3D V5.0. This is apparent when you realize that many advanced 3D printer manufacturers bundle Simplify3D with their equipment, as it’s likely one of the best slicing options for them. Simplify3D is a professional tool, not a hobbyist tool.

This is part two of a two part series, please read part one.

Via Simplify3D