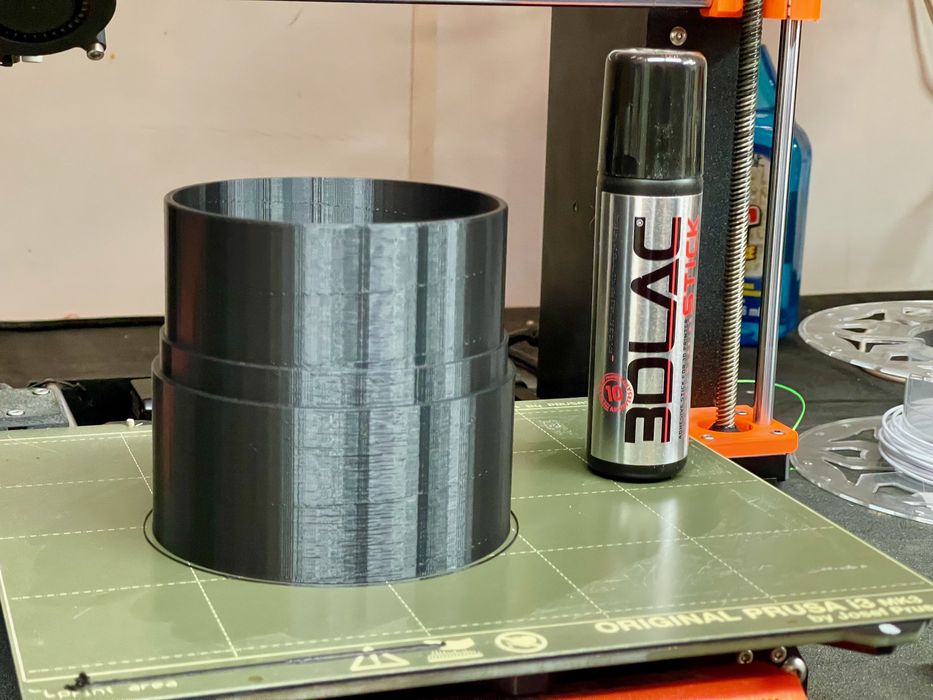

We tested 3DLAC’s stick-style adhesion solution.

Adhesion is critical for FFF 3D prints, and was a significant problem for the early years of desktop 3D printing. Back then the typical build plates were plain metal, glass or even acrylic, and no material stuck properly. Many unusual and sometimes silly solutions were attempted, including use of painter’s tape, hair spray and Kapton tape applications.

None of these were optimal, and that’s when Spain-based 3DLAC originated. The company sought to solve the problem by producing an easy to use adhesive solution that solved the problem of adhesion during printing, but release after printing.

They succeeded, and ten years later they have a suite of products to address a variety of adhesion needs.

They current offer four products:

- 3DLAC

- 3DLAC Plus

- 3DLAC Stick

- 3DLAC Nylon

The nylon product is, as you might expect, focused on nylon material, which is notorious for challenges in sticking to the build plate. The other products are best for ABS, PLA and PETG materials.

The products use a manual spray system for delivering the solution to the print bed, but we tested the stick version. It operates in a very simple manner and is quite easy to apply. Some other products, and in particular hair spray, are not entirely safe to use.

We found we were able to cover the build plate best by using a two-way approach. Moving the stick back and forth on the X-axis, and then repeating on the Y-axis. This ensures you hit all the spots in-between your passes. You must wait until the fluid evaporates before using the printer, which doesn’t take very long.

Our tests used a stock Prusa MK3S+, with its standard build plate. This plate has a coating that is normally quite usable for adhesion, but in some cases the model geometry and materials are such that warping can occur.

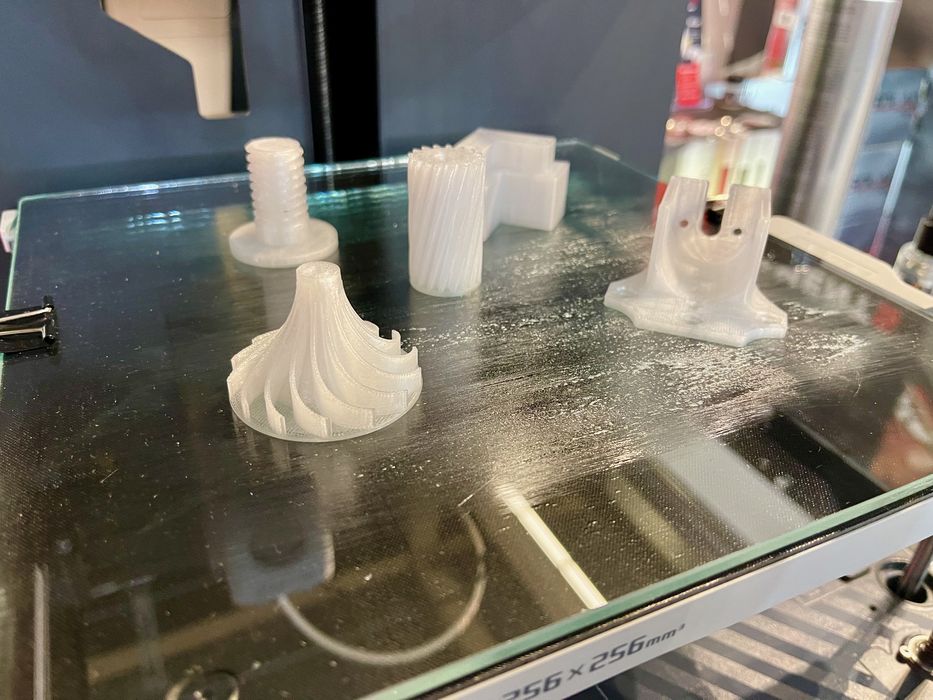

We tested several prints using the stick, and all were quite successful. While the plate is hot, 3DLAC does provide significant adhesion. However, the product does not release the print until the plate is sufficiently cooled. In our testing this didn’t matter much due to our operational process: prints would be sitting for a while after completion anyway.

However, if one is running production it might be best to have separate build plates. The idea would be to immediately remove the hot build plate with print attached, and the install a clean plate for the next job. The prior plate can sit alone as it cools enough for the print to be released. That would be a way to keep production going as much as possible.

3DLAC is sold individually, but the company also offers 2, 3, 5 or even 12-packs for those requiring a great deal of solution.

We did not have the opportunity to test the nylon version, but I am quite interested to do so. Nylon materials are particularly challenging to print because they tend to warp quite severely.

If you’re in need of an easy to use adhesion solution for your FFF 3D printer, you might consider trying 3DLAC. It works very well.

Via 3DLAC