Charles R. Goulding and Preeti Sulibhavi look at how 3D printing use can be increased by shipyards constructing and refurbishing vessels.

In the September 2022 edition of WorkBoat magazine, there was an article that illustrated the ship building boom currently being experienced by companies operating in the US Gulf Coast. A major part of the article focused on how this boom is benefitting the US military, specifically the Naval forces.

In an in-depth review of recent shipyard developments, the article detailed recent activities of various shipyard giants, including Bollinger, Eastern Shipbuilding Group, Huntington Ingalls, General Dynamics (Electric Boat), and Austal USA, to name a few. The crux of the article was that all these developments are helping to keep the men and women in the US Navy ready if and when needed. The article also included vessels sent to Ukraine as part of military aid packages to that nation.

Bollinger Shipyards acquired Gulf Island Fabrication in Louisiana last year, increasing the number of shipyards it owns to eleven, and expanding its construction repair capabilities to better serve both its defense and commercial clients. Also last year, the Navy awarded US$3B to Ingalls for the USS John C. Stennis (CVN-74) refueling and complex overhaul (RCOH). This further expands Ingalls’ reach in the industry.

The Navy is putting heavy emphasis on utilizing 3D printing technology for submarine parts to ease the strain on its industrial base. The US Navy plans to pair suppliers who cannot keep up with demand with additive manufacturing (AM) companies who can print parts around the clock to boost the supply.

Shipyard Building & 3D Printing

The 3D printing industry is no newcomer to shipyard building and marine activities.

We have covered 3D printing for boatyards and marina consolidations in previous articles. While the 3D printing industry is not new to shipyards, recent developments in Ukraine and US defense activities are bringing this topic into the limelight.

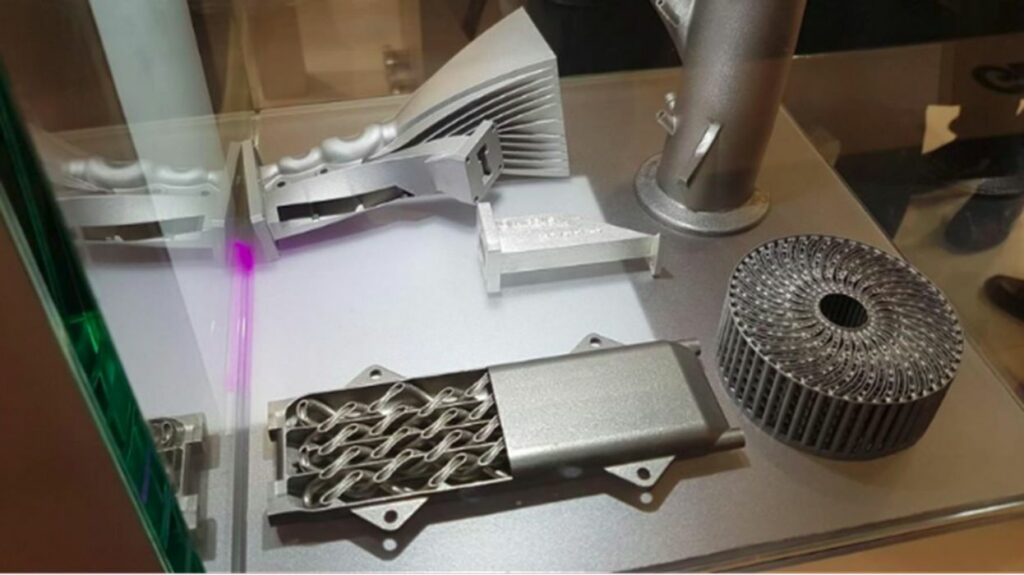

Navies (not only the US, but as we have mentioned those of other nations, too) have obviously been seeking 3D printing technologies for some time now because of its durable yet flexible prototyping abilities for components and replacement parts. For instance, 3D Systems worked with Ingalls to create replacement parts with unique geometries (see below).

The shipbuilding industry is replete with examples of how 3D printing is being used to either prototype customized parts or create quick replacement ones. With the shipbuilding industry increasing collaborative efforts with the military, complex design and geometries are inevitably going to be involved. 3D printing can provide solutions in this regard.

This summer Austal USA, of Mobile Alabama, was awarded a US$3.3B dollar contract for the design and construction for up to eleven offshore patrol cutters for the Coast Guard.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Shipyards are one of the oldest industries that continues to strongly innovate. The US Navy has been collaborating with shipyards and utilizing 3D printing for creating replacement and other parts. With the present crisis in Ukraine, we anticipate 3D printing to become even more integrated into the creation of new vessels.