Charles R. Goulding and Preeti Sulibhavi look at recent high-profile 3D printing activity in Italy.

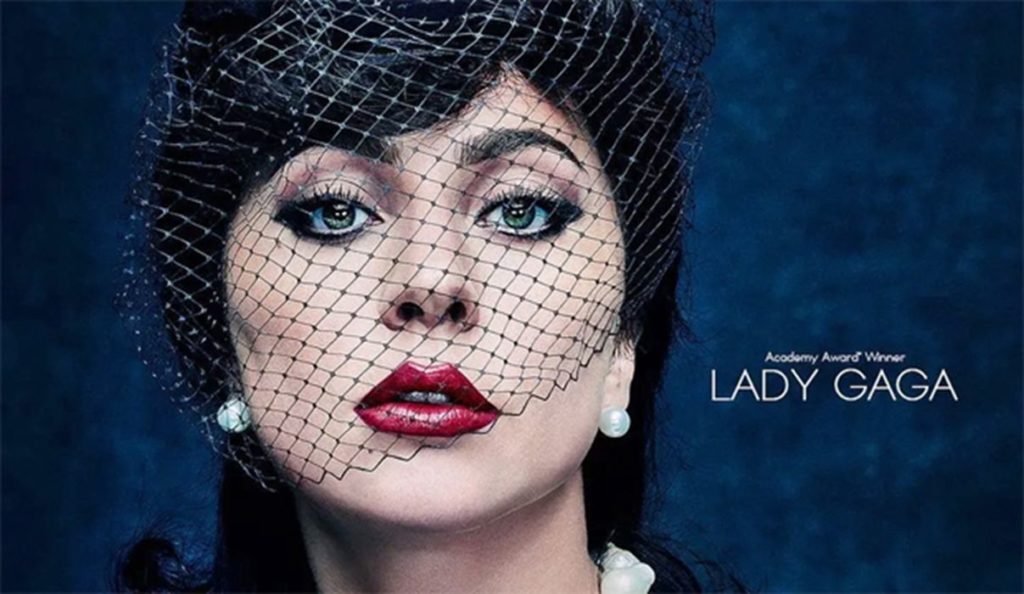

The House of Gucci movie now playing in theaters focuses on crime and intrigue at one of the world’s leading fashion houses. The all-star cast features Lady Gaga as Patrizia Reggiani, Jared Leto as Paolo Gucci, Adam Driver as Maurizio Gucci, Al Pacino as Aldo Gucci, and Selma Hayek as Giuseppina “Pina” Auriemma.

The picture above demonstrates how Gucci is already in the metaverse, using avatars in the virtual world.

Years before the movie, Jared Leto carried a 3D Gucci model of his head.

Gucci sells a wide range of high-end fashion products, many suitable for 3D printing, including apparel, accessories and footwear. Robots are in fact making $650 Gucci sneakers. Housed in Gucci’s ArtLab prototype factory in Florence, referred to as “Reingenious,” is a patent-protected robot assembling shoes. Gucci CEO, Marco Bizzarri, estimates that “as much as 30-35 percent of Gucci’s production can be completely automated in the not-too-distant future.”

In the meantime, fellow Kering-owned brand, Balenciaga, is taking to the tech realm to increase production. “Demna Gvasalia’s fall 2018 show for Balenciaga was revolutionary for fashion,” proclaimed Cathy Horyn in 2018. “To my knowledge, it’s the first time a major luxury brand, and one with a legacy of architectural elegance to boot, has used 3D printing and molding technology to produce tailored coats and suit jackets.”

Italy itself has become a leading user of 3D printing technology. We have covered how Italy’s digital renaissance has been enhanced, with help from 3D printing and how Italy is making a spectacle with 3D printed eyewear. According to the Wohler’s 3D Printing Industry Report for 2019, it was estimated that the 3D printing industry will have exceeded $35 billion in sales by 2024.

The Italian automobile industry has also been utilizing 3D printing technologies. Whether it was Sir Jony Ive joining the Ferrari team or our coverage of the motion picture, “Ford vs Ferrari,” Italy is replete with examples of how the auto industry is benefitting from this technology.

Barilla, the world’s leading pasta company, makes extensive use of 3D printing technology. 3D printing is not new to the pasta world. Founded in Italy in 1877, family-owned and operated for four generations, Barilla, the world’s largest pasta company, has been busy making pasta relevant in today’s world. In fact, about six years ago Barilla created a fun competition for finding new shapes of pasta using 3D printing technologies. Entries for the Smart Pasta competition must include a 3D printable design and a brief explanation. Utilizing 3D printing technologies for pasta improves the design quality, texture and shapes of pasta. The thickness of the pasta walls also matters for optimal cooking.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The pandemic greatly accelerated the use of 3D printing for apparel & PPE including, masks, gowns and gloves. Italy already has a strong 3D printing foundation. We would anticipate much wider use of 3D printing technology in many of the world’s leading fashion houses and, in particular, Italy.