A 3D printed solution could allow breakthroughs in brain research.

Stem cells are the most powerful of all cells, as they have the unique ability to produce, given appropriate stimulus, any of the body’s cells. Scientists have been using the capability to study the growth of different parts of the body.

One area of deep interest is brain cells. By understanding more about how they interact, researchers could unveil the mysteries behind many brain diseases, such as Alzheimers or Parkinson’s.

The approach is to use stem cells to produce “organoids”, which are small self-organizing clumps of cells that exhibit the same micro-behaviors as found in living bodies. This is done by dropping the cells into a bioreactor, a small unit that allows for a variety of functions during the experiment.

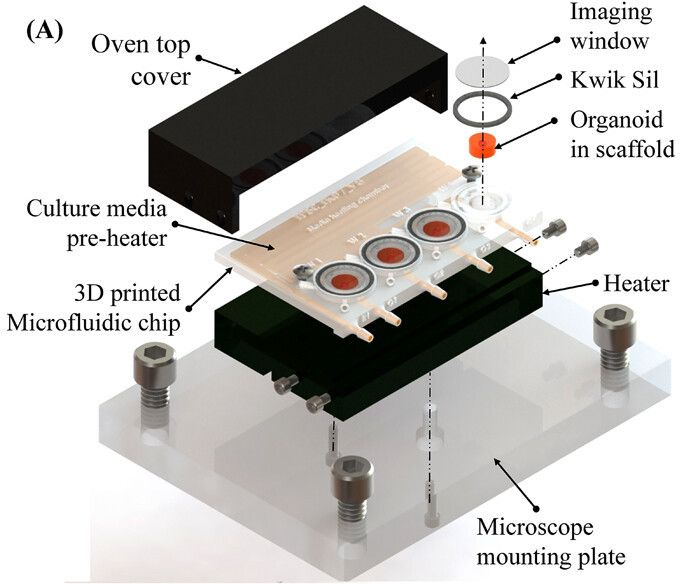

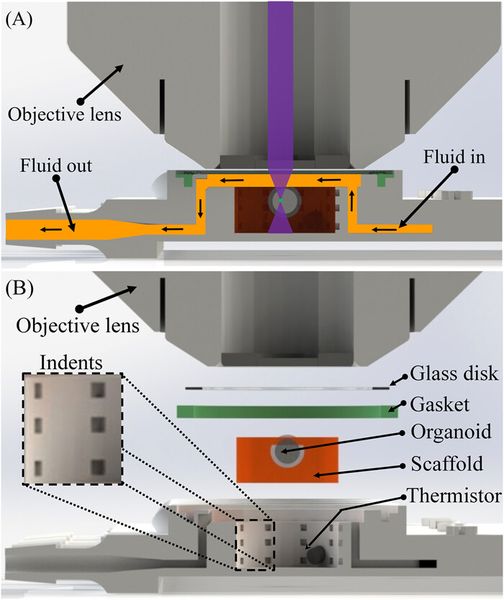

Cells will have to be provided with nutrients, otherwise they will perish. Temperature must be continuously monitored and adjusted, otherwise they will perish. Finally, the entire process must be observable and likely recorded in various ways. The bioreactor “chip” is a fairly complex structure as a result of these requirements.

Normally these chips are produced using conventional means, and the process involves casting of silicone materials. That making process imposes a number of design constraints, as Fabbaloo readers will no doubt be aware of.

Instead, researchers at the Department of Electrical Engineering, Indian Institute of Technology worked through a new method of producing bioreactor chips using 3D printing.

In SOLIDWORKS they designed a chip that included a well to hold the tissue and surrounding culture; ports for nutrients and drug flow; thermistor; and a viewing surface. The chip has a clear top that allows viewing into the culture well.

Their 3D printer was a common Form 2 SLA 3D printer, not even the most current unit available from Formlabs. While there is no “bioreactor resin” available, the researchers chose instead Formlabs’ Dental SG Biocompatible Resin, which, as you might suspect, is biocompatible and thus appropriate for this application.

The bioreactor chip was printed in 0.05mm layers, cured for one hour in a UV bath, then sterilized at 120C under pressure. The result was a fully functional bioreactor chip that the researchers then used to investigate the growth of brain cells.

The most interesting part of this project was the fact that the bioreactor chips were produced at a cost of only US$5 each. That’s significantly lower than traditional bioreactor chip costs, and should lead to increased cell investigations as researchers can stretch their grant money a lot further.

Via AIP