If 2020 has taught us anything, it is that modern medical science is perhaps the closest thing to a miracle we’re going to find in today’s day and age. Every day, new technologies are being developed to save lives. Every moment, someone, somewhere, is creating a new treatment or making a new discovery that will restore quality of life to those threatened by illness or injury.

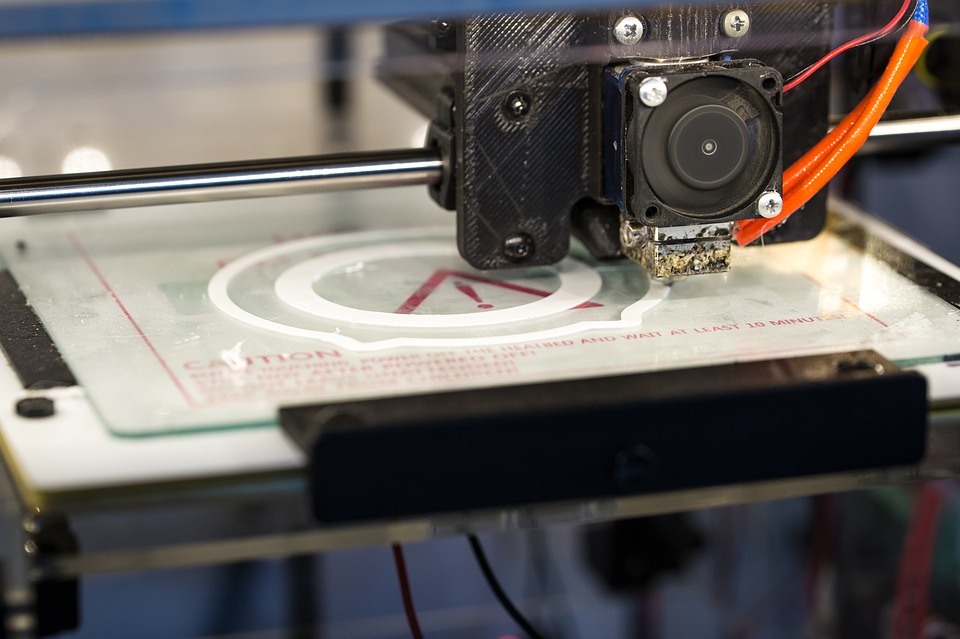

Sometimes, though, those life-saving and life-changing innovations come from very unexpected places. Case in point: medical 3D printing. The very tool you can find in any office and almost every home is increasingly being incorporated — in modified form, of course — into the healthcare industry. So the next time you or someone you love needs care, you may well find your doctor firing up a 3D printer to provide it.

How It Works

Even if you’re already familiar with 3D printing as opposed to conventional printing, you might be wondering how, exactly, this tool originally designed for industry and manufacturing can be put to safe medical use. In fact, standard 3D printing and medical 3D printing use the same basic principles and processes.

3D printing in all its myriad forms is based on additive manufacturing (AM) processes, which means that an item is constructed through layering, building the object from nothing, one layer at a time. This is a marked difference from traditional manufacturing processes, in which objects were carved or shaped from blocks of materials.

The primary difference between standard and medical 3D printing is in the type of materials used in the manufacturing process. Not only does the latter rely on medical-grade materials, but it can even use human and synthetic cells in scaffolding and drip layering processes.

Being able to build an object from scratch makes 3D printing infinitely customizable, enabling the on-demand production of almost any item a person, business, or even an entire industry might need. A perfect case-in-point has been provided by the COVID-19 pandemic itself.

3D printing technologies have proven to be a rockstar in COVID times, being used to quickly meet the immense demand for everything from personal protective equipment (PPE) to nasal swabs for testing to machines for patients requiring ventilation. The technology has even been used to rapidly construct entire shelters for healthcare providers and those under quarantine.

Beyond COVID

Innovations in medical 3D printing did not begin with COVID, however, nor will they end there, In fact, the research suggests that we’re only just beginning to understand the immense potential of this technology. And that’s leading to several important changes in the practice of healthcare in general, such as the fact that now more than ever, clinicians need to have a solid grounding in the latest technology. After all, medical 3D printing is only as effective as the people who use it.

For example, when combined with today’s ultra-sensitive medical imaging, medical manufacturers can create customized prosthetics and biological implants that are quite literally mapped to the specific and unique dimensions of patients’ bodies. As an outcome, patients are less likely to suffer from complications resulting from a traditionally-manufactured device, such as wounds, abrasions, or infections from ill-fitting prosthetics.

Not only that, but custom-created prosthetics and implants simply perform better. This is particularly evinced in their increasing use by athletes with disabilities, those for whom performance excellence isn’t just a perk but a necessity.

Saving Lives and Saving Money

Perhaps one of the more unexpected benefits of the evolving technology is the reduction not only in overall healthcare costs but also in out-of-pocket costs to the patient. And in an era of rising medical debt, where patients find themselves turning to credit cards to cover payments that can’t be negotiated with the hospital, care provider, or insurance company, these cost savings can make a big impact on your family’s overall financial wellbeing. Plus, these savings can help you avoid having to use your cards to pay medical bills.

Studies show, for example, that surgical procedures executed with the help of some kind of 3D technology, such as the use of custom implants or surgical models, were on average 62 minutes shorter than the same procedures conducted without these tools. The result is nearly $4000 in cost savings.

The Takeaway

Today’s 3D printing technology is about far more than increasing productivity and efficiency in the manufacturing industry. It’s not even only about whipping up the latest tool, gadget, or toy on your home 3D printer. Thanks to innovations in the healthcare industry, medical 3D printing is demonstrating its power both to save lives and to make life better. Additive manufacturing enables surgeons to quickly create surgical models that exactly replicate patients’ anatomy. The capacity for customization enables the development of prosthetics and implants that fit and perform better than ever before. And they can rapidly create most anything a caregiver might need to take care of the patient while also taking care of themselves, from PPE to quarantine shelters to most anything in between.