After considerable development, Fusion3 announced their new EDGE 3D printer.

The North Carolina manufacturer has produced very high quality equipment for many years, with their flagship F410 device leading the way. At least, that is, until now.

The new EDGE 3D printer inherits much from the F410, which has been used by their customers for “millions of hours” of successful 3D printing. Let’s take a look at the specifications of the EDGE device.

- Large build volume of 355 x 355 x 368 mm

- Passively heated build chamber up to 70CFast 64-bit ARM controller board

- Seven inch color touchscreen

- Automatic maintenance reminder system

- Upgraded motion system including linear rails, able to hit 200mm/s for some materials

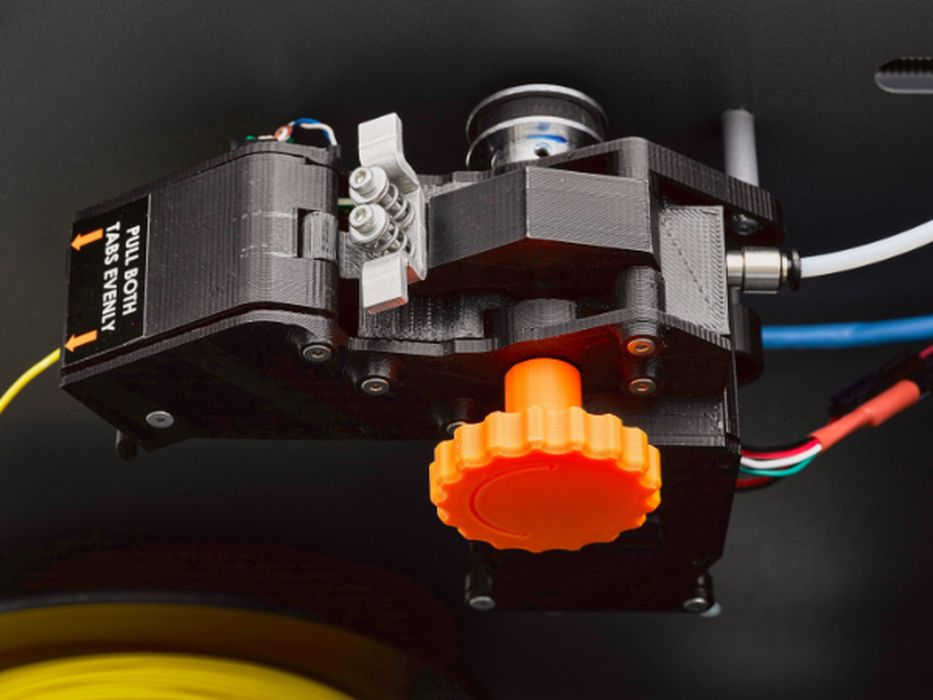

- New belt driven extruder with filament out detection

- Ultra quiet operation: only 37.5dB when operating

- In-machine active spool storage

A couple of new features deserve special mention.

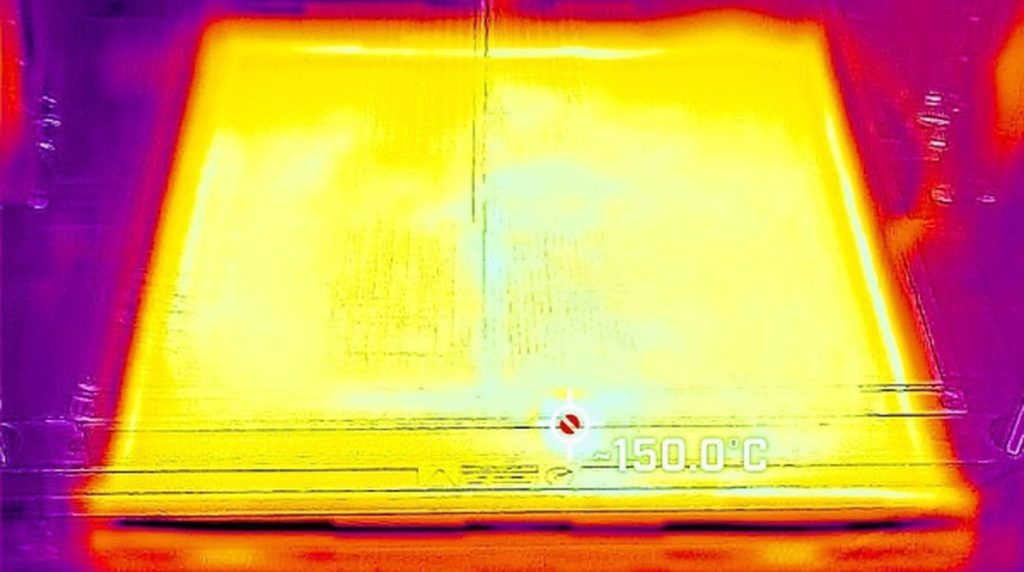

The print surface is notably upgraded. There is now a 1/4” (6mm) aluminum plate topped with a glass surface. This should distribute heat very evenly and allow adhesion for a wide variety of materials. Along with this print surface, the EDGE includes a new bed leveling system.

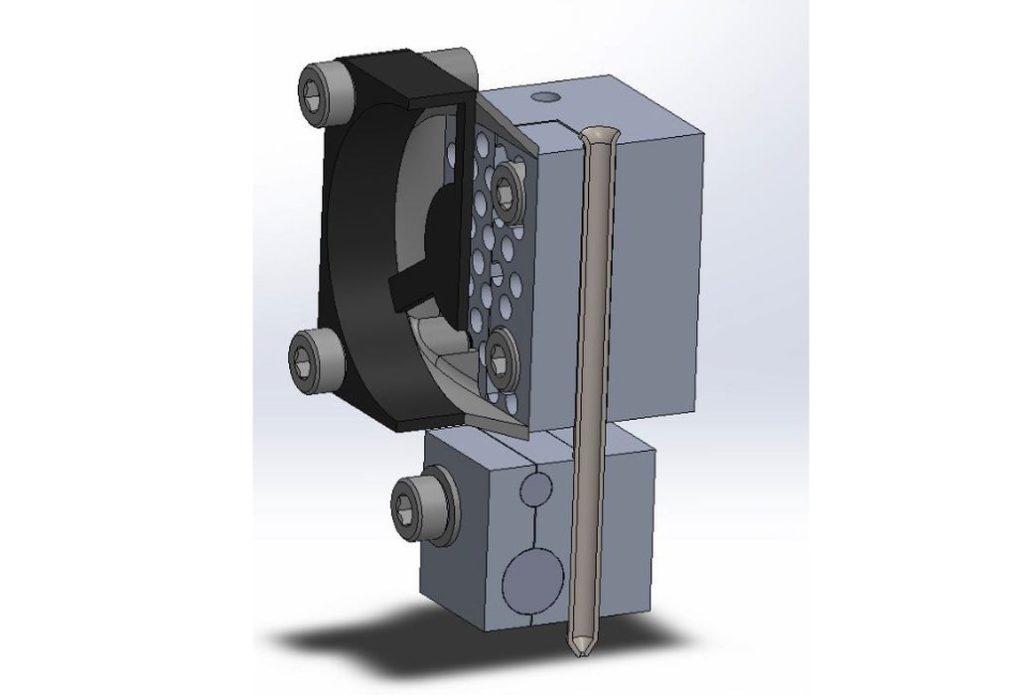

The printhead is entirely redesigned and is now called “ANVIL”. It’s main feature seems to be the use of a surgical needle instead of the traditional screw-in nozzle. This is quite interesting, and I haven’t seen this used elsewhere. Fusion3 explains more:

“Fusion3’s patent-pending ANVIL print head system incorporates a surgical steel print tube instead of a traditional screw-in 3D printer nozzle. Use of a single print tube provides faster printing and is wear- resistant for use with abrasive filaments such as carbon fiber or fiberglass-reinforced filament. In addition, the single tube design is more reliable, eliminating the chance of leakage. ANVIL is easier to maintain translating to lower operating cost.”

I’m curious how this works and especially how print jams are cleared with the ANVIL design.

Fusion3 said that with all these new features, the EDGE will be able to handle a very wide range of materials, including “PLA, ABS, ASA, Reinforced Materials including Carbon Fiber, Kevlar and Fiberglass, Flexible, Nylons, PET/PETG and Polycarbonate”, and more.

For safety the EDGE now includes a door interlock system that will automatically pause an active print job if the door is opened. This makes it a bit safer as it may prevent accidents caused by wandering fingers. There’s also an optional HEPA/Carbon filter that would make this machine ideal for educational environments.

Fusion3 has also developed a special “secure” version of the EDGE for the military or other organizations that require extreme security. What makes the EDGE secure? Basically they’ve disabled the USB port and WiFi networking, making it possible to operate the EDGE only through its ethernet port. This version also ships with a special version of the REACTOR software that does not require internet access.

The EDGE also includes an industry-unique TWO year warranty; the most you’d receive elsewhere is a one year warranty. In addition, Fusion3 will provide phone and email support without pause as long as you own the machine.

Finally, the EDGE is priced at US$6,999, and you can request quotes including shipping as of today.

Via Fusion3