A company has re-used microscope technology to create a powerful new metal 3D printer.

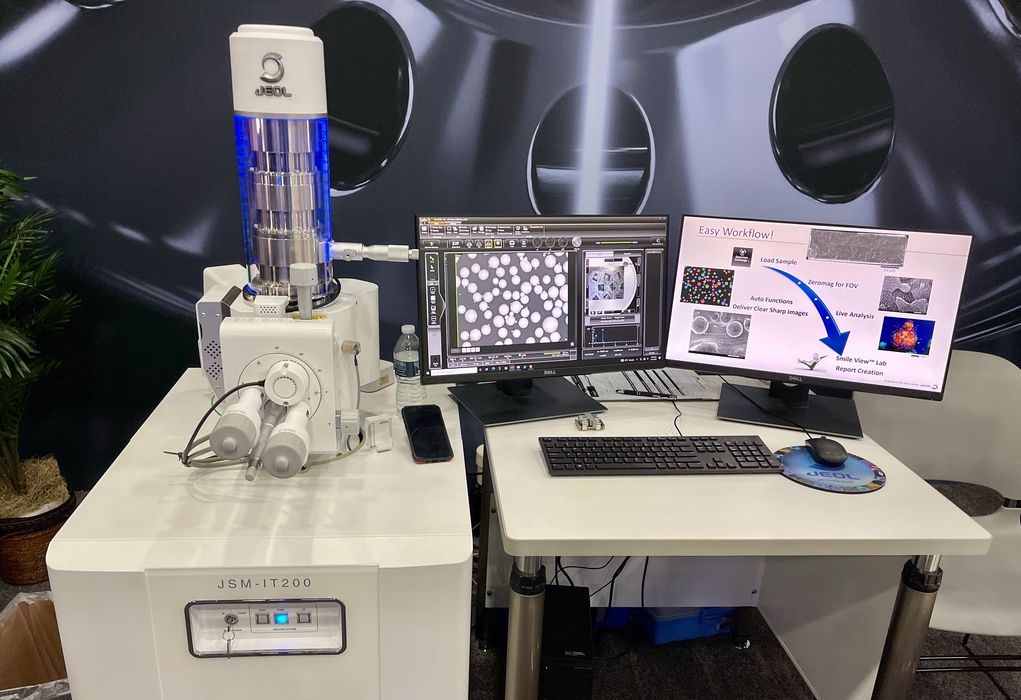

JEOL, based in Tokyo, is not a new company. They’ve been around since 1949, long before the arrival of 3D printing technology. Back then, and today, their primary product is electron microscopes.

An electron microscope is a device that blasts high speed electrons at a target and uses them to illuminate the object instead of standard light waves. The approach allows the electron microscope to achieve incredible magnifications, up to 10MX with resolution of 50pm (that’s 0.0000005mm). With such a microscope researchers are able to peer into the microscopic world and see inside living cells and crystalline structures.

Recently the company has adapted their electron microscope technology to create a new kind of metal 3D printer, which was first released in 2021. Called the JAM-5200EBM, the device is targeted at industry and is able to produce high quality parts with great efficiency and repeatability.

Most metal 3D printers use either laser or electron beams to selectively melt powder beds, and that’s what’s happening with JEOL’s technology, which is similar to EBM.

JEOL claims a number of advantages for their system over conventional EBM technology as used by companies like ARCAM.

The most notable benefit is that the cathode on their system lasts an incredible 1500 hours, far longer than those on normal EBM 3D printers.

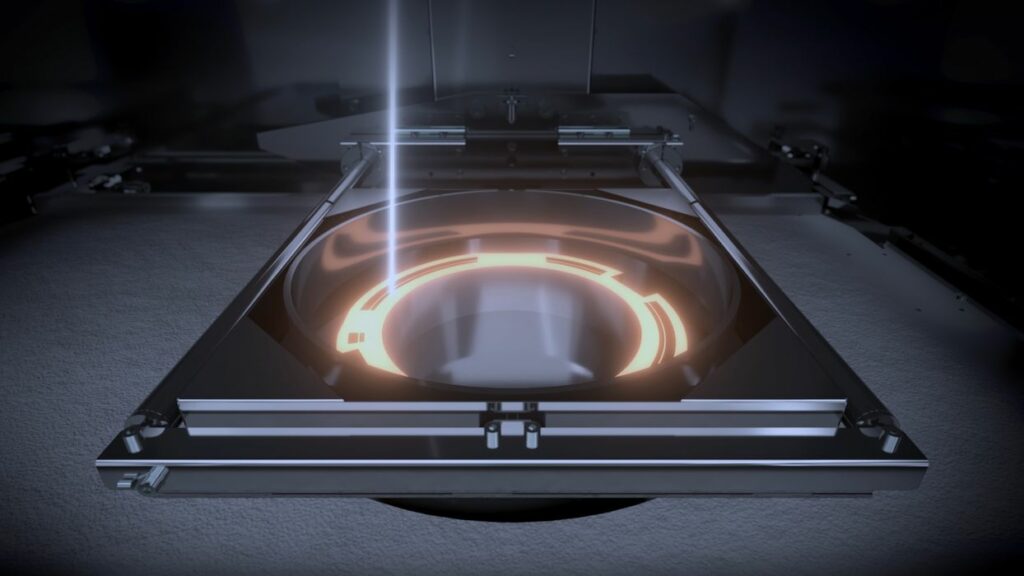

How does JEOL achieve this? It’s actually quite ingenious. They don’t use helium to prevent powder scattering in their system, but they do have a shield that fits over the build plane. This “smoke free” shield is transparent to the electron beam and keeps the smoke away from the cathode because it is blown out under the shield. This also means the machine can continue to produce the same high quality parts for the duration of the cathode’s lifecycle.

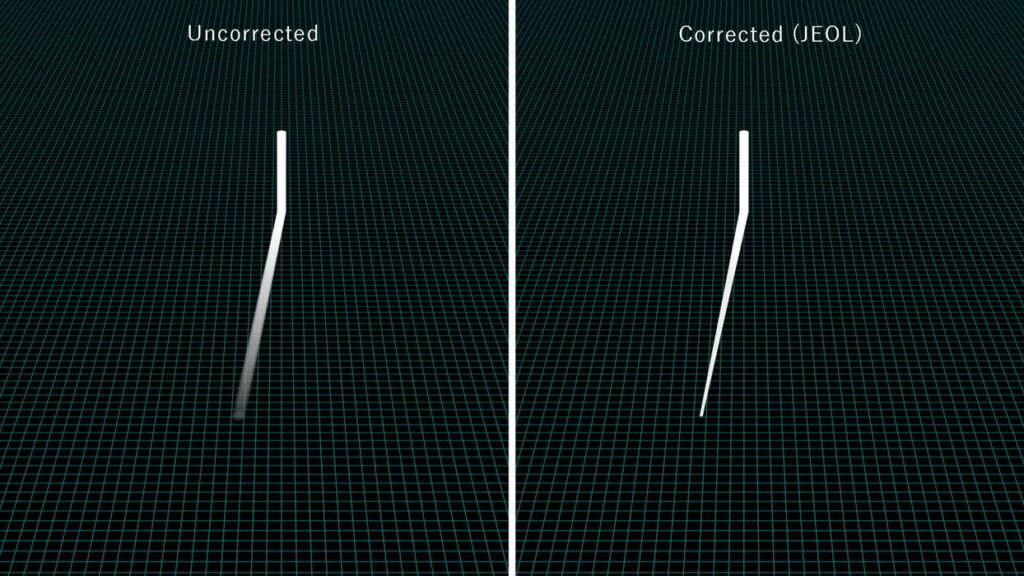

Another interesting feature is “automatic electron beam correction”. This is a dynamic feature that is inherited from their semiconductor manufacturing technology, which results in much higher quality parts. The requirement to mark semiconductors with great accuracy is the same requirement for melting metal powder.

The JAM-5200EBM has a cylindrical build volume of 250mm diameter by 400mm tall, able to build many metal parts. It’s possible to stack parts together as seen in this image of 190 sake cups, all printed in the same print job.

As a newcomer to the 3D print space, JEOL does have a significant advantage: their existing sales and service network exists worldwide. Other new market entrants don’t have that ability, but JEOL will be able to service equipment anywhere right away.

The JAM-5200EBM system is a fascinating story of leveraging a different technology into 3D printing. One might think that development of new 3D printing technologies might be over, but it really is not, as JEOL is an example of an alternative approach that provides great value.

Via JEOL