Formlabs announced a new scan-to-print feature that demonstrates how 3D printing should really be approached.

The company has recently been focusing on the dental market, even announcing a 3D printer specialized for that market, the Form 3BL. They offer a wide selection of dental resins and would appear to have everything one would need to use their equipment to produce dental models.

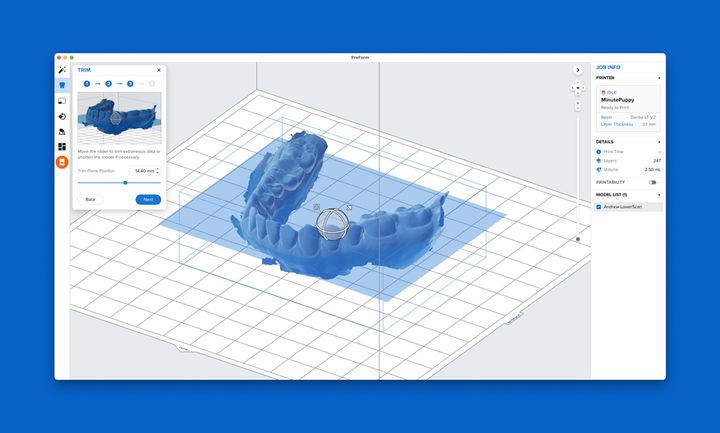

However, with the announcement of their new ”Scan to Model” feature in their PreForm software, they tie it all together.

Scan to Model appears as a very appropriate “tooth” icon in PreForm, and invokes a short workflow for dental technicians. A 3D model is imported and several standard transformations occur to prepare for 3D printing. Then, the model is 3D printed. Formlabs says the models can be printed in as little as 20 minutes, if using draft mode.

This may not seem to be a big thing at all, as these would be very typical steps taken by a 3D printer operator to produce models. But in this case remember that a dental technician IS NOT A 3D PRINTER OPERATOR!

They are dental technicians, highly trained in another discipline, and the idea of 3D printing would be generally strange and mysterious to them.

When you’re in a business and something proposed seems strange and mysterious, you usually don’t bite. Why change what’s already working? Why spend the effort to learn something that will probably do exactly what you already have?

In other words, that line of thinking would, for many potential Formlabs clients, shut down any notion of purchasing a system.

The Scan to Model feature gets around this brilliantly, and this is evident in a short video prepared by Formlabs:

Imagine you’re a dental technician with suspicions of the probably difficult-to-learn 3D printing work being proposed, and you’re watching this video.

Does it change your mind? You bet it does. This sequence is so straightforward anyone could do it. In fact, while I watched it I realized the most likely issue in their minds would be “where to put the system in the office?”

This is how Formlabs is breaking down the barriers to using 3D printing in a much bigger way. It’s not just having a competent machine and materials; it’s also enabling the potential customers to use it in the easiest possible way, and making sure they know it.

I always say, “If you want something to happen, make it easy”, and that is precisely what Formlabs is doing here.

I’m hoping other 3D printer manufacturers take note and pay more attention to the specific needs of their client areas. By simplifying the workflows this approach can transform a purchase from a difficult decision into a no-brainer.

Via Formlabs