Formlabs appears to be looking for someone to lead their engineers.

The Massachusetts-based company launched way back in 2011, and first appeared as a Kickstarter campaign in 2013. It has grown tremendously, and today is one of the most successful survivors from the crazy early days of desktop 3D printing. Today they sell well-designed equipment globally, and hundreds of people work for the organization.

Maxim Lobovsky, the co-founder and current CEO of Formlabs, said in a recent LinkedIn post:

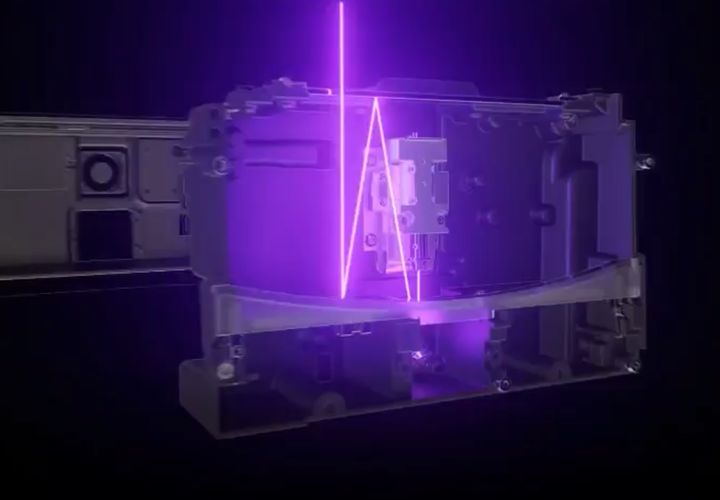

“I am looking for someone to lead engineering [at] Formlabs. Overseeing 150+ engineers and driving development of the next generation of 3D printing technology. If you (or someone you know) is equally capable and interested in going to the whiteboard to design something like this ⬇ or working on organizational design or performance review systems, I’d love to talk to you.”

(The arrow refers to an animation of the SLA laser process, a frame of which we have included at top. I should have changed the arrow’s direction, I suppose).

There’s a couple of things to take from this announcement.

First, Formlabs is intending on developing a “Next Generation of 3D printing”. This is an intriguing statement because the basis of their existing 3D printing process is actually quite old: it’s basically the SLA process.

Could this mean Formlabs intends on tweaking the SLA process? Or is this something different? The phrase “Next Generation” could imply something radically different, or perhaps merely an improved version.

It could be that the animation shown by Lobovsky hints at what is to come, although it appears to be an exploded view of the company’s Form 3 technology.

Lobovsky also uses the phrase, “organizational design or performance review systems”. To me, this is code for management activities. It would appear that Formlabs is interested in revamping their engineering department and its development process.

That’s surprising, given the success they’ve had so far in designing what is likely the easiest-to-operate resin 3D printer we’ve yet seen. Perhaps they intend on going even further in that respect? Could they develop a machine that is even simpler?

Are they intending on instituting some type of radical product development process? Would it enable them to produce more interesting products in less time? It’s hard to say.

However, the answer to many of these questions might be determined by the successful candidate. After all, they’ll “lead engineering”, and their innovative ideas might become reality.

That’s a definite possibility given that Formlabs is very well-funded at this point.

If you are a lead engineer, you might want to give Max at Formlabs a call.

Via LinkedIn