Formlabs announced today a partnership with an automotive company, and this has some interesting implications for the 3D printer manufacturer.

Their new partner is Vital Auto, a UK-based custom car design firm that works with a selection of high-profile automotive clients. Their work is to take ideas from clients and transform them into physical life-size models that typically appear at major automotive trade shows.

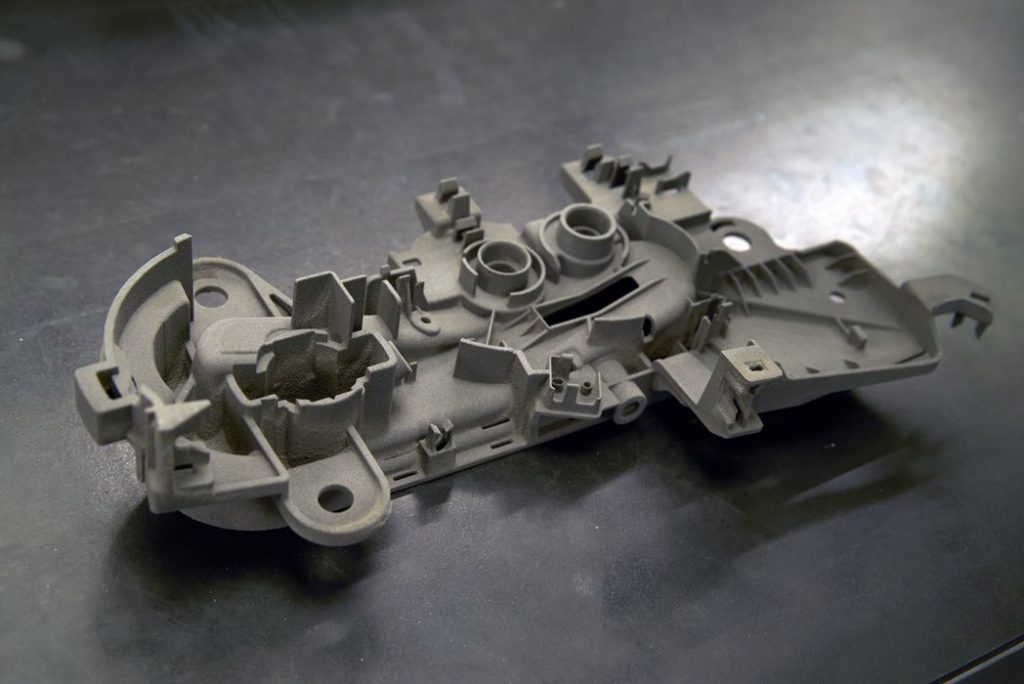

As you might expect, Vital Auto has to produce a great deal of custom parts for these models, and their workshop includes a number of different making devices, ranging from CNC to 3D printers, as well as most of the major 3D CAD software tools.

While Vital Auto has long used 3D printing, they have only operated FFF equipment until now. In fact, they apparently built their own custom large-format FFF 3D printer with a massive build volume of 2800 x 1200 x 1000 mm. Currently they operate 14 large-format FFF 3D printers.

But having a large format 3D printer isn’t the end of the story. As is almost always the case, multiple types of 3D printers are required for complex projects because each type offers different advantages.

According to Formlabs’ press release, Vital Auto now operates three Form 3L resin 3D printers, and six Fuse 1 SLS devices. With these devices Vital Auto will have at their disposal the three primary 3D printing processes: FFF, SLA and SLS. They should be able to produce many different types of parts and in general make their work much easier.

In fact, the addition of this equipment has dramatically sped up the company’s workflow. Formlabs explains:

“With Formlabs 3D printing technology working to create rapid prototypes and end-use parts, Vital Auto’s sped up its three to 12 month custom concept car production timeline which has also attracted new business from automakers who seek companies with the cutting technologies and materials to produce the futuristic cars we can’t imagine yet.”

Vital Auto’s Design Engineer in charge of additive manufacturing, Anthony Barnicott said:

“What interests me most about the Form 3L machines is their versatility, the ability to do a material change in less than five minutes and the variability of those materials going from a soft, flexible material to a hard and rigid material for us is priceless.”

Formlabs SLS Strategy

This is all good news, and is typical of companies moving from traditional to additive approaches: the cycle time for parts is dramatically shortened, and that usually makes for increased productivity and additional revenue.

But I think there’s more going on here with Formlabs. Let’s take a look at the company’s progression through the years:

- Develops breakthrough low-cost desktop SLA 3D printer

- Markets the device as a general purpose tool

- Decides to focus on the dental market, and grows dramatically

- Develops breakthrough low-cost SLS 3D printer

- Markets the device as a general purpose tool

Can you guess what the next step could be?

Formlabs first found a profitable market for their SLA equipment in the dental industry, which up until that time had been suffering from very high costs of a few long time 3D printer manufacturers. Their offering was well-received by the dental industry at first due to the far lower cost, but later the breadth of their offering.

My suspicion is that Formlabs wants to repeat this strategy with their Fuse 1 SLS device. Remember, SLS is not a technology typically used by dental labs, so the company’s expertise, networking and reputation in the dental market won’t help the Fuse 1.

They have to make a new market for the SLS device, and with today’s announcement, I have now expect that to be the automotive market.

Their partnership with Vital Auto could be the first of many. Vital Auto is also a very strategic partner because that company’s customer list will be exposed to the Formlabs parts. Their exposure might, eventually, transform into new Formlabs customers.

This could be an indirect, “try it, you’ll like it” maneuver, and might be the beginning of something big for Formlabs.

Via Formlabs and Vital Auto