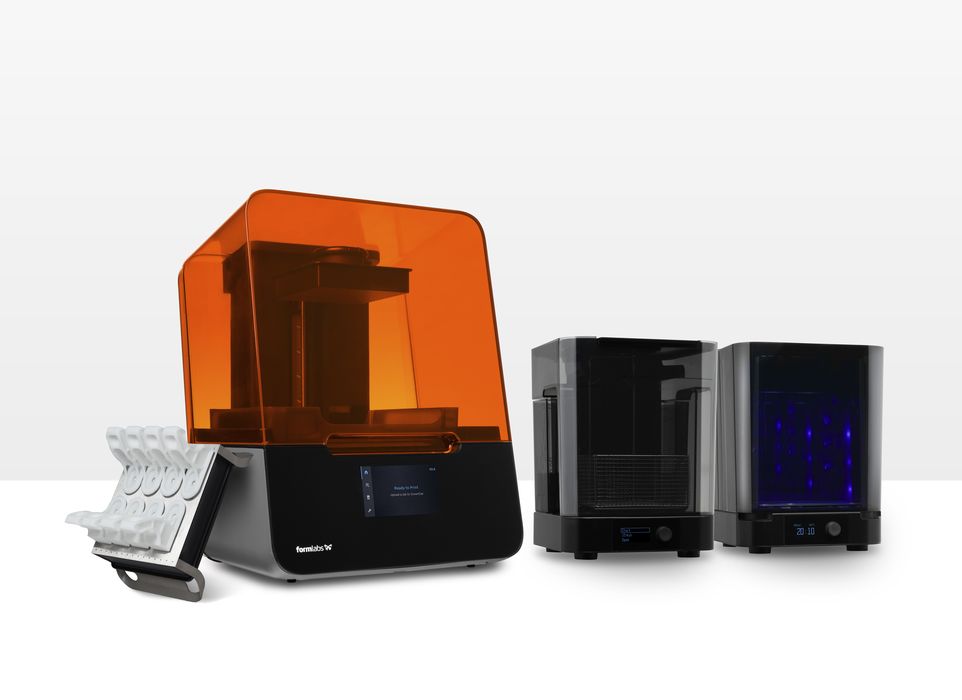

Formlabs announced a new 3D printer, the Form 3+, with an amazing feature.

It’s not that often that Formlabs announces a new flagship 3D printer, but they have done so today. They actually announced two models, the Form 3+ and Form 3B+. The Form 3B+ is identical to the Form 3+, except that it is optimized and certified for biocompatible 3D printing operations. Formlabs said:

“Formlabs will announce the launch and shipping of Form 3+ and Form 3B+, their fastest 3D printers to date, available and shipping globally today. These printers are the result of three years of work improving their trademarked Low Force Stereolithography technology that was first introduced in 2019. These new iterations entail enhanced hardware components and software updates that significantly improve print speed, print quality, support removal, and provide an overall better user experience.”

While there are several new features in the Form 3+ models, the one that instantly caught my eye was the revolutionary new build platform, which Formlabs has predictably labeled as “Build Platform 2”.

Formlabs Build Platform 2

At first it appears to be a standard build plate that would securely attach to the Z-axis on the Form 3+.

But then if you turn it over it can do this!

Those curious handles on the sides of the Build Platform 2 are actually used to twist the spring steel build plate!

Why do this? It’s a way to immediately remove prints from the build plate without any issues. Normally prints are chipped off a build plate with anger, often resulting in damage to the print, and sometimes the 3D printer operator, too. Those days will be gone with the Build Platform 2: you merely pull the handles and prints should easily pop off.

This brings an ease-of-use feature long seen in FFF 3D printers to the SLA world.

That’s not all. The Form 3+ models also have a number of other very attractive features.

Form 3+ Specifications

The first will be speed. As Formlabs stated above, they have been working on their LFS technology for quite a while, and the benefits are seen in this model, which apparently can 3D print up to 40% faster than previous models.

They’ve also achieved tighter alignment between the laser unit and the build platform, which also reduces print time by “5 to 15 minutes” in the first few layers of each print job.

Surface and overall print quality is also improved by new stabilization components in the laser system, as well as new air flow mechanisms and thermal measurement to maintain consistent heat throughput each job.

The laser power is increased in these machines, but it doesn’t seem to be due to a more powerful laser. Instead they have squeezed out more power with some engineering trickery. They explain:

“An expanded laser power operating range, a reworked motion profile for the LPU, faster galvanometer moves, and other key print process improvements have unlocked 20-40% faster print speeds on many resins.”

I asked about how the older models fit into this new technology and was told that existing Form 3 and 3B resin tanks and materials can be used on the new Form 3+ and 3B models. Also:

“The improvements released with this launch will also improve print speeds for Form 3 and Form 3B users on many of these materials.”

Formlabs suggested that these new LFS improvements will benefit operators in that they will “open up previously unattainable material profiles”.

Form 3+ Pricing

What is the cost of the new models? Formlabs is pricing them at the same price as the older models, suggesting that they’re actually swapping in new flagship models to take over from the older units on their product shelf. They’re also available right now, with immediate shipping.

This is an impressive upgrade, and notable in that it is available at the same price levels. It will be of particular interest to those using Form 3s for production: increased print speeds will generate more throughput, which should make the machine significantly more profitable. Also, the new Build Platform 2 will reduce post processing labor, also adding to the productivity boost.

This is a good upgrade.

Via Formlabs