Flashforge has introduced a new 3D printer that’s way out of their normal scope.

The company is well-known for their desktop 3D printer line, which they began producing way back in 2008. You might not realize that Flashforge was one of the first Asian companies to enter the desktop space, at the time competing with the likes of MakerBot, Ultimaker and Solidoodle.

In the early days the company produced equipment similar to the MakerBots of the day. However, since then they’ve gone on to develop quite a range of devices.

This year they launched something quite different, the Creator 4.

Unlike their prior equipment that was mostly targeted at consumers and prosumers, the Creator 4 is their first machine that’s truly dedicated to professionals and the industrial market.

What makes it different? Let’s look at the specifications:

- Rigid stainless steel frame

- 7” color touch screen

- Fully enclosed build chamber, heated to 65C

- Huge build volume of 400 x 350 x 500 mm

- Dual independent extruders

- Precision motion system with steel rails

- Interchangeable nozzles, with 0.4, 0.6 and 0.8mm available

- Nozzle temperature up to 265C

- HEPA filter to remove odors and particles, potentially enabling office use

- Webcam for remote monitoring and control

- Power failure recovery process

The heated chamber means the Creator 4 can 3D print a wide range of engineering materials. Flashforge lists these materials as being possible to print:

- PC

- PA

- PP

- PETG

- ASA

- ABS

- PLA

- PC-ABS

- PACF

- PET-CF

- PP-CF

- PA- GF

- PC-ABS

- PP-GF

- PPS-CF

- TPU 85A

- TPE

- TPB

- TPC

That’s quite a list of materials.

Flashforge has made an arrangement with LEVHOSS, the noted German chemical company and producer of high quality polymers, to produce their own certified line of filaments, Flashforge Supreme. While Flashforge would prefer you use these filaments, it’s also possible to use any thermally compatible third party materials as well.

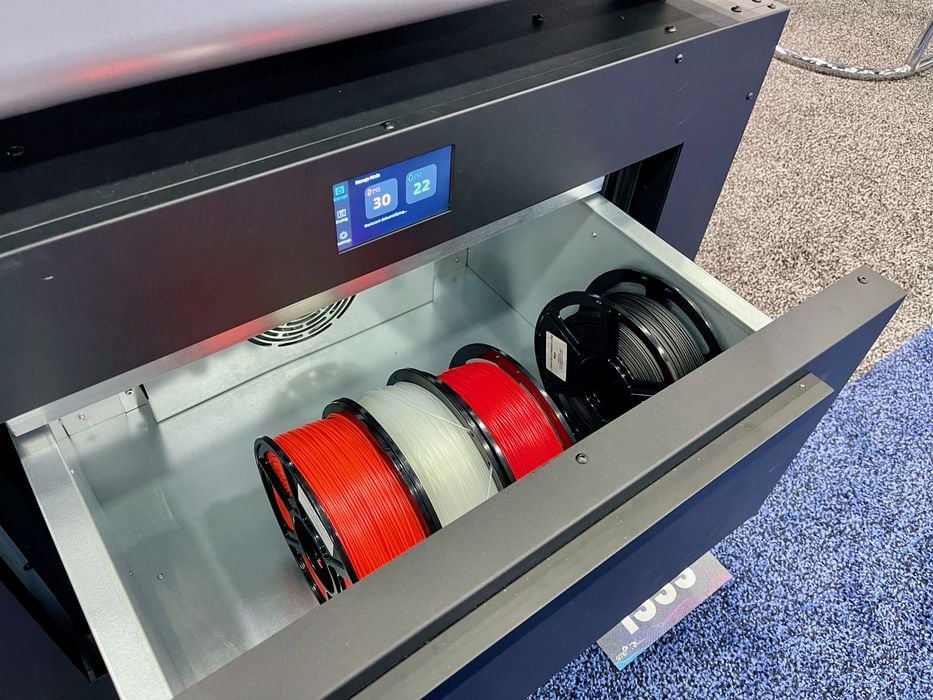

Along with the Creator 4 is an accompanying Filament Drying Station that can serve as a stand for the Creator 4. This item also includes rollers so that you can easily move the entire system.

Most importantly, though, the drying box will ensure the materials used in the Creator 4 are properly conditioned. Many engineering materials, particularly nylons, tend to absorb humidity from the air and this can dramatically compromised print quality. Flashforge is attempting to solve that issue with the Filament Drying Station.

When you look at all these features, it adds up to a system that’s ideal for professionals looking to print prototypes in many engineering materials.

As for Flashforge, we were told the Creator 4 is “the first” of many commercial 3D printers that could come from the company. It seems they, like many other desktop 3D printer manufacturers, are moving into the more profitable professional market.

Via Flashforge