Researchers have successfully installed 3D printed parts into a nuclear reactor.

The Manufacturing Demonstration Facility at the Oak Ridge National Laboratory (ORNL) has designed and 3D printed four parts that have been installed into a working nuclear reactor, as part of the “Transformational Challenge Reactor” (TCR) program. The reactor in question is the Brown’s Ferry Nuclear Plant Unit 2 in Athens, Alabama, operated by the Tennessee Valley Authority.

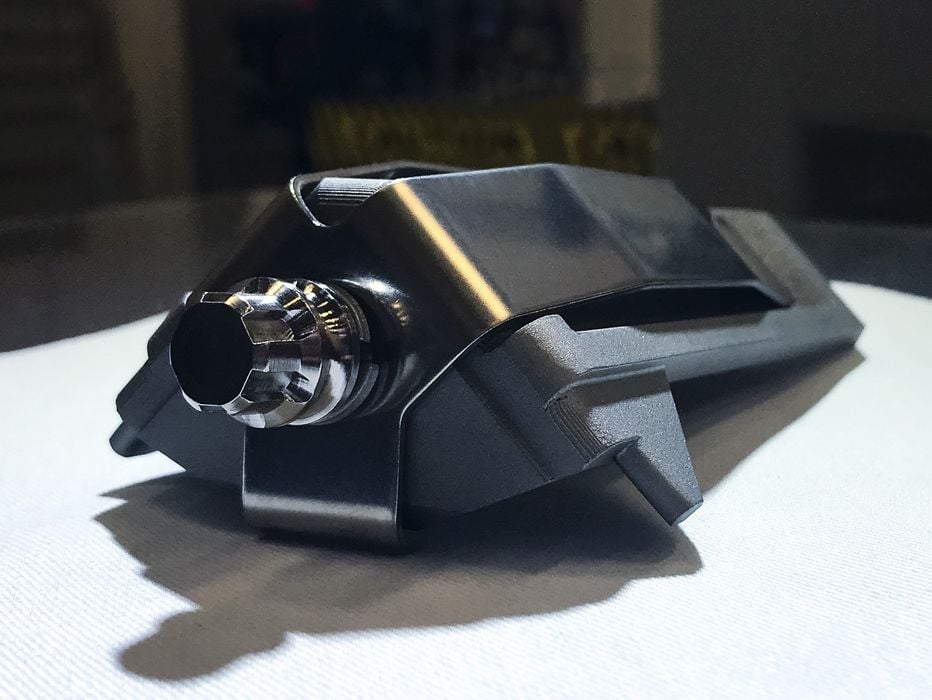

The parts involved were channel fasteners for a boiling water reactor fuel assembly. The plan is to leave these new additive components in the reactor for up to six years, with periodic inspections to ensure they remain fully functional.

It may seem straightforward to design and 3D print a few parts for a system; this is commonly done each and every day using 3D printers and different materials. However, there’s a massive difference here.

Nuclear reactors are perhaps the most regulated system in existence.

One of my pet sayings to convince someone they’re doing something too complicated for the job is to say, “It’s not like we’re running a nuclear reactor here!”

But in this case, they literally are running a nuclear reactor.

In order for the parts to be installed, they had to undergo extremely rigorous testing and certifications, far more than in normal applications.

TCR program director Ben Betzler explained:

“Deploying 3D-printed components in a reactor application is a great milestone. It shows that it is possible to deliver qualified components in a highly regulated environment. This program bridges basic and applied science and technology to deliver tangible solutions that show how advanced manufacturing can transform reactor technology and components.”

In a way, this milestone is perhaps the ultimate test of 3D printing: if a 3D printed part can be successfully installed in a nuclear reactor, 3D printed parts can be used in any conceivable application. That’s a state the 3D printing industry has never achieved, until now.

No longer will it be reasonable to dismiss the notion of 3D printing for applications.

Of course, this doesn’t mean that 3D printing can be used on every application. It just means that 3D printing can be considered a viable option, along with all the traditional making methods. Any choice made for an application must meet all requirements, including both engineering and financial.

But as of this moment, 3D printing is now by default on the list for consideration.

Via ORNL