Researchers have identified a method of easily — and ecologically — disposing of PET thermoplastics.

PET is one of the more popular materials used in 3D printing these days, along with PLA and ABS. While each of these can “easily” be recycled due to their thermoplastic nature, all is not quite what it seems.

Any thermoplastic can be simply heated and reformed — into a new filament, for example. That’s how commercial filaments are made, and you can even purchase self-operated filament machines that can accept recycled 3D print scraps.

This effectively suggests to many that it is a simple matter to collect 3D printed scraps and recycle them. However, the truth is actually more devious.

For 3D printed scraps produced in a workshop, it might be easy to collect them, but there’s a chemical barrier: unless all scraps are the same material from the same source, there’s little point in mixing them together when recycling.

The scraps might be different materials. Is that leftover raft made from PLA or ABS? Who knows? Oh, some scraps are red and some are purple? Can we mix those? Are these two gray scraps identical? Yes, they are almost the same color, but did they come from the same manufacturer / batch and have the same chemistry? Does that one use toxic lead for coloration?

Recycled 3D print material with unknown origins leads to unpredictable and inconsistent 3D prints. That’s not something anyone wants, particularly with today’s highly accurate and well-performing 3D printers.

For general recycling the same type of problem exists: if someone collects thermoplastic scraps, are they really the same material? Some green initiatives get around this problem by having scavengers pick up only one type of empty drink bottle (typically made from PET), and even then only from a specific drink brand. That way they are mostly guaranteed to have near-identical input material, but the vast majority of plastic waste is ignored.

These challenges are essentially impossible to rectify.

The outcome is that we will all be swamped in leftover 3D prints, sooner or later. If we can’t recycle them, what can we do?

We can dispose of them.

Dropping them in a landfill won’t help because typical 3D print materials don’t degrade. In fact, PLA can’t easily be recycled and requires high heat, pressure and chemicals to decompose. PET is similar.

What about burning them? That’s possible, but aside from the atmospheric pollution, which could be toxic depending on the material’s chemistry, that is also not desirable or scalable.

Now there may be another approach that is quite different and ingenious.

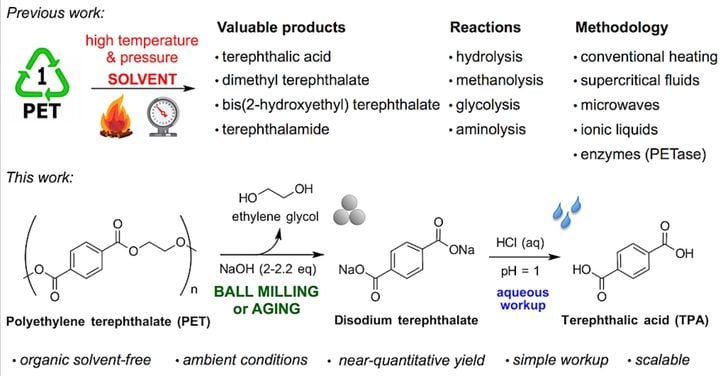

Researchers attempted to decompose common PET using a mechanochemical approach. This is a method that employs mechanical stress in addition to chemical means. However, it turned out their discovery uncovered a very straightforward process.

Their approach simply involves apply ball milling within a humid environment. According to their research there are specific milling durations and milling media required to achieve optimal PET decomposition. This process should be easily scalable to industrial sizes, and does not require the use of toxic solvents, high temperatures or other non-green factors.

They explain:

“An efficient and clean solid-state alkaline depolymerization of waste PET into terephthalic acid (TPA) under organic solvent-free conditions has been developed. By employing mechanochemical ball milling, aging or their combination, near-quantitative PET conversion and TPA yields are achieved at ambient temperature and pressure which is hardly attainable by traditional solution-based methods.”

Their method accepts PET scraps, a bit of humidity and time in a mill to break down the PET polymer into simple monomers that can be reused for other applications.

If this technique could be applied to the other common 3D print materials, we might suddenly have available a means to properly dispose of leftover 3D prints in a way that actually makes sense.

Via Wiley