FabWeaver is looking to a summer shipment date for their new A530 3D printer.

If you haven’t yet heard about FabWeaver, it wouldn’t be surprising. It is a new brand from Sindoh, long-term makers of 3D printers.

Sindoh is a South Korean company that’s been around for decades, and is among the world’s leaders in the production of advanced photocopying equipment, along with a broad variety of other electronic equipment.

Some years ago they decided to get into the 3D printing business and launched their first machine, the 3DWOX, a desktop device.

Our 3DWOX review showed that their device was perhaps the first to provide an easy-to-use touchscreen by leveraging their photocopier interface expertise. At the time it was a revolutionary development, and we called the device the “first real 3D printer for consumers.”

The company then went on to produce a series of improved 3DWOX devices, each more complex and sophisticated. Eventually, their equipment reached into professional and eventually industrial capabilities.

However, the equipment was still branded as 3DWOX, which in the minds of some was associated with the original inexpensive desktop devices, and not proper industrial equipment. The result was the introduction of the new FabWeaver brand, which will focus on industrial and prototyping applications.

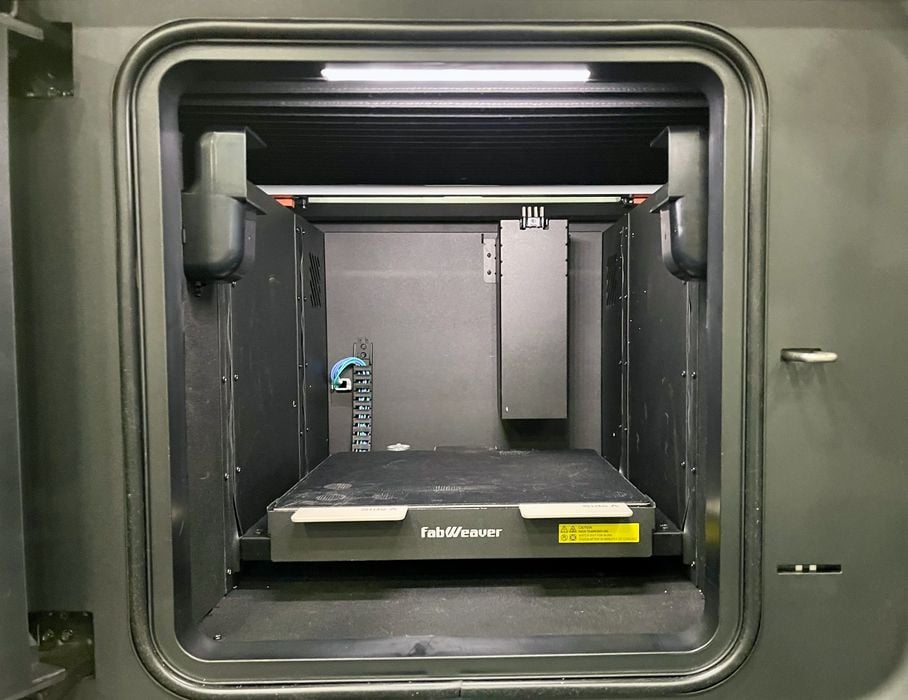

The first FabWeaver device is the A530, shown at top. It’s designed as a professional prototyping machine, and offers a number of features for that market.

A530 Specifications

The FFF device includes key elements for reliable production of quality prototypes:

- Closed loop controls to ensure accurate positioning

- Dual extrusion for use of soluble supports on complex 3D prints with their RSA material

- Enclosed chamber to allow use of engineering materials

- Consistent chamber temperature of 75C to avoid part warping

- Non stop printing via the “smartStation” four-cartridge automatic feeding system

- Color-coded lighting system to immediately alert operators of job outcomes

- Huge color touchscreen at eye level for easy operation

- Build volume of 310 x 310 x 310 mm

- Power recovery procedure during outages

- Hot end temperatures up to 290C

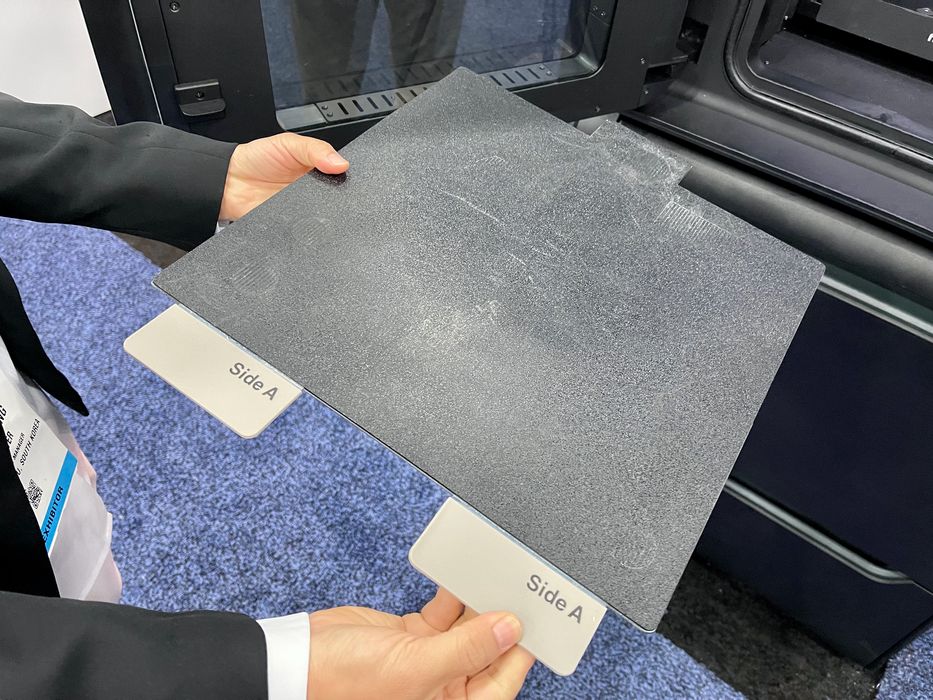

- Automated leveling procedure

- Automated Z-gap calibration

These features combined together produce a device that’s capable of consistently 3D printing within 0.2mm tolerance of each and every part. It’s able to reliably produce parts that fit correctly without post processing.

It’s easy to see that the A530 is very carefully designed. For example here we see a “bellows” on top of the build volume. This separates the electronics from the heat of the build chamber and should extend the lifetime of the machine.

The materials currently available on the A530 include ABS & PLA, with their own RSA support material. I strongly suspect they will be adding to the list of available materials as the machine should be fully capable of printing other engineering polymers.

FabWeaver said the base price for the A530 is about US$6,000, but with the associated table and feeder it rises to about US$10,000. The machine should be available in July from FabWeaver.

Finally, FabWeaver told us they are now seeking resellers for their line of professional devices. Any resellers reading this post might consider giving them a call to find out more.

Via Fabweaver