I spoke with Admatec about their latest 3D printer, the Admaflex 130.

If you’re not familiar with Admatec, they produce small-to-medium sized 3D printers that can produce ceramic objects. They are one of the very few companies that specializes in ceramics.

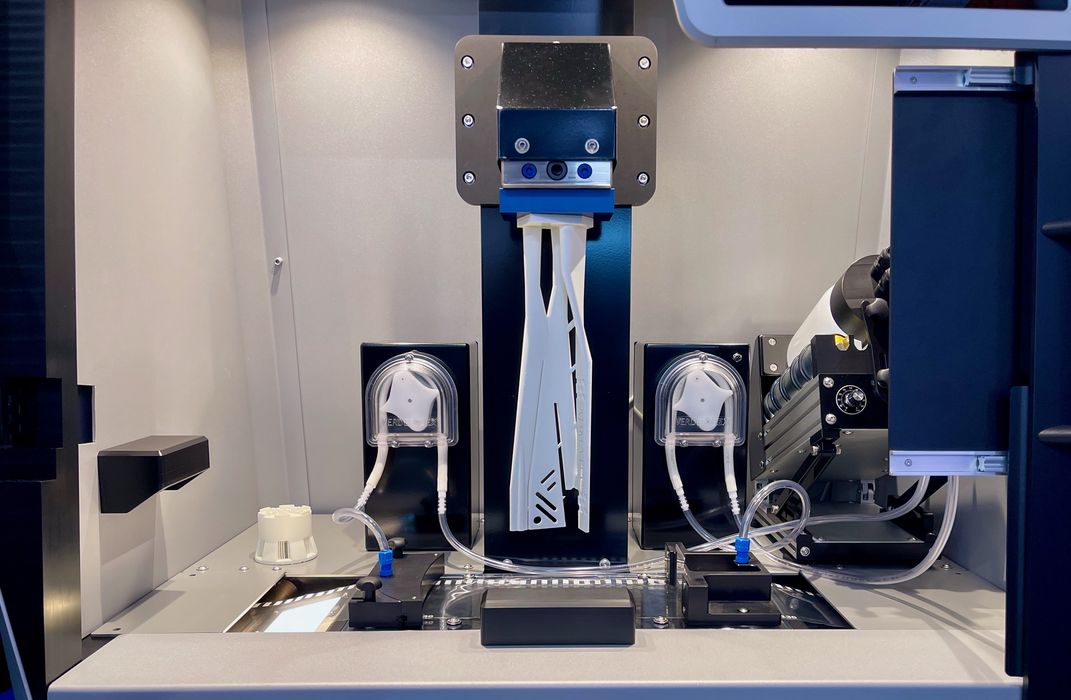

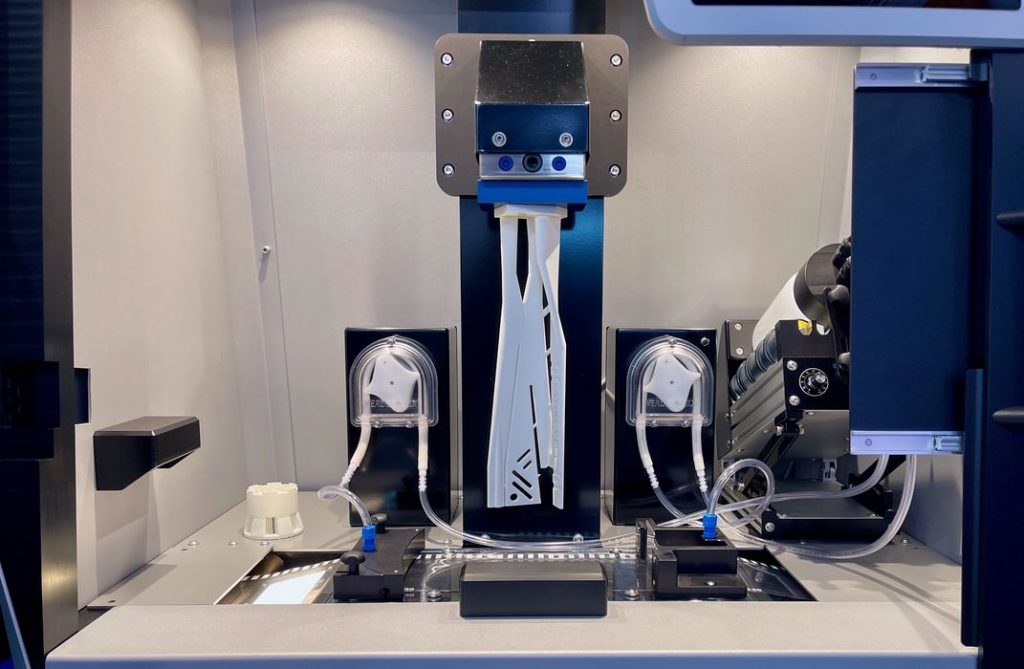

Their 3D printing process is unique: it involves a rolling belt on which is deposited a thick fluid layer of ceramic material. The belt stops under the print head, which uses the photopolymer process to “pick up” some thick resin from the belt. The belt then rotates a bit to bring a fresh layer of resin under the print head once again. This process repeats until the object is complete.

At that point you’ve created a green part that will require debinding and sintering to form the final ceramic object. Admatec’s process can produce extremely detailed and precise ceramic objects that can be used for industrial purposes.

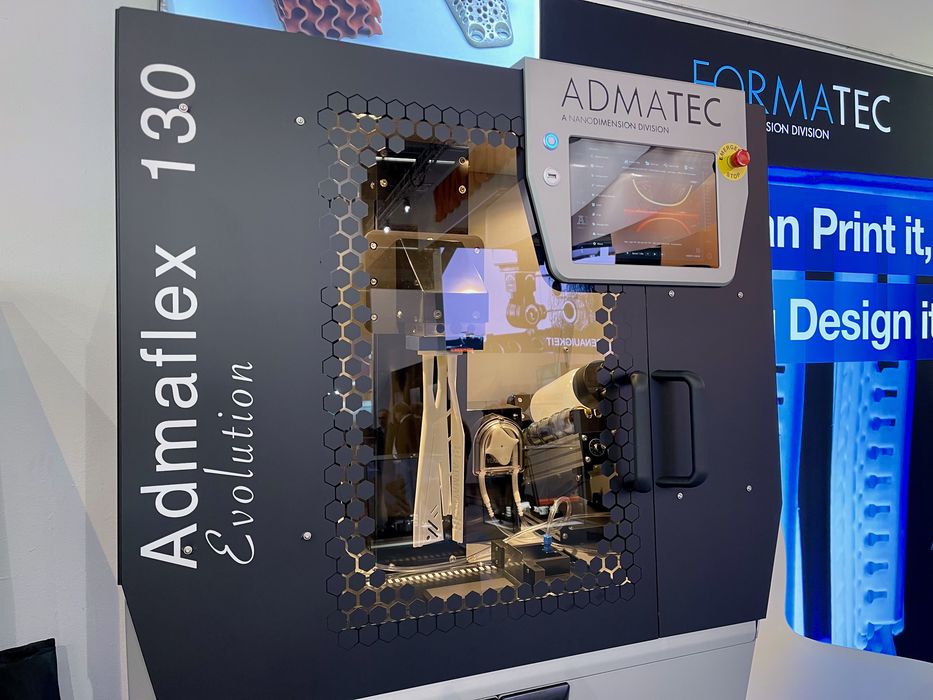

What’s new in the Admaflex 130? We were told that it’s basically the same as previous models, but there are few interesting improvements.

One is the styling. The 130 now has a lot less glass than its predecessors, although there is still a window to see into the build chamber.

The reasoning for this is actually economic: apparently the glass was “expensive”, and it turned out customers didn’t really care whether there was more or less attractive glass coverings. They’re mostly interested in just getting the part done properly.

Another improvement is in the pumps that deposit the thick resin on the belt. The new pumps are more powerful and can handle more viscous slurries.

This is quite important because resins are always a mix of photoinitiators and the “real” material. Strong materials require stronger — and thus thicker — resins. SLA, MSLA and similar processes cannot handle such thick resins, but Admatec can.

In fact, the new 130 model can handle even thicker resins.

Even better, the entire system is also “open materials”, meaning customers are able to experiment with their own resin combos to develop unique and powerful ceramic materials. Of course, it’s easier if you use Admatec’s materials that have pre-set print parameters, but they’ll help you figure out the parameters for new experimental materials, too.

Another improvement in the 130 model is the addition of more onboard cameras. These record the print process and make it easier to follow back to see what happened in failed prints. It’s also possible for operators to intervene if necessary by viewing the print in progress.

If you’re interested in a high-performance ceramic 3D printer, the Admaflex 130 is one to consider.

Via Admatec