Charles R. Goulding and Mwansa Chabala discuss the advantages of friction stir welding technology as it applies to additive manufacturing.

Friction stir welding (FSW) is a welding technology that was invented and patented in the UK by researchers at The Welding Institute (TWI) in 1991. Revered as one of the most groundbreaking discoveries in its industry in recent decades, its advent has seen large corporations such as Boeing and Hitachi creating their own patents related to the process.

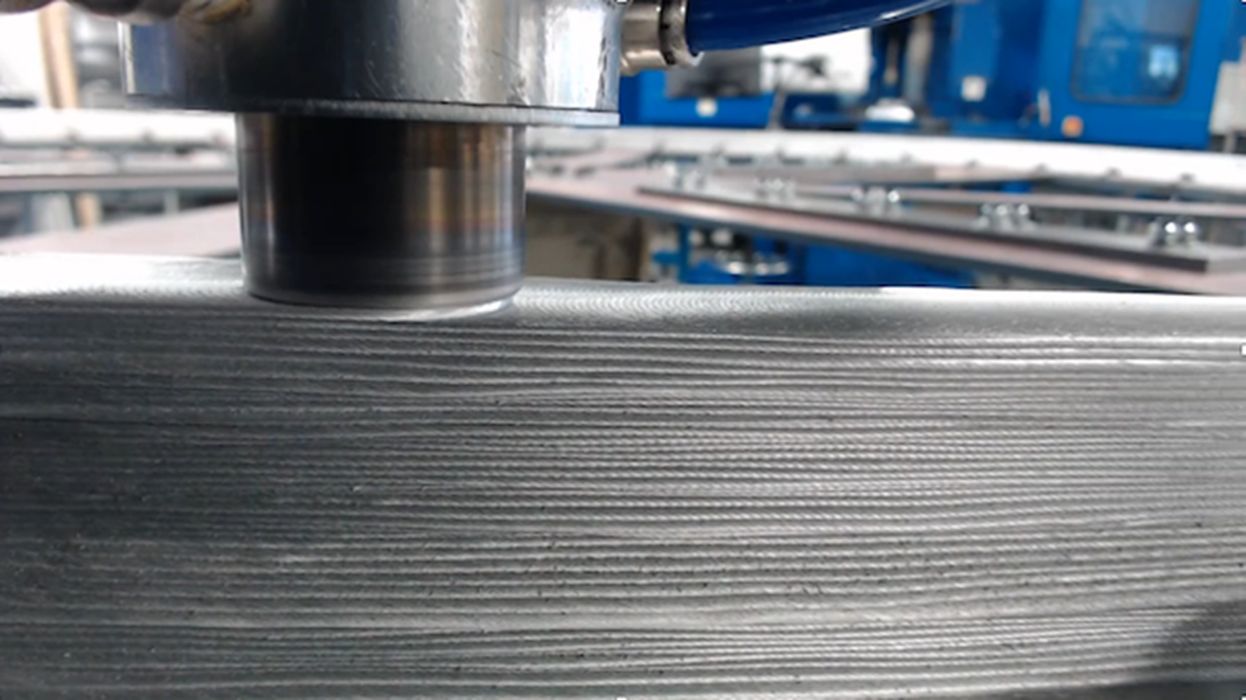

FSW is a solid-state welding process that utilizes heat from friction between a non-consumable rotating tool and the workpieces to be welded. The friction heat, coupled with adiabatic heat within the material and that from the mechanical mixing process, allows the workpieces to soften without melting. This technique has made it possible to weld such pieces as alloys of aluminum, titanium, steel, magnesium, and nickel-base superalloy, among other nonferrous metals. Unlike conventional welding methods, FSW allows for welding dissimilar materials, while maintaining a precise and clean weld with a significant reduction in porosity, defects, or distortion. In more recent years, the welding technology has been successful in welding polymers.

To explore and advance the science and technology of friction stir processing (FSP), the University of North Texas (UNT) has a dedicated Center for Friction Stir Processing (CFSP) that has grown to become an internationally recognized center for FSW and FSP, among their other variants. Several publications have been published, detailing such applications as methods of manufacturing alloys and rare earth metals.

Friction Stir Additive Manufacturing

FSW has also seen applications in additive manufacturing in a process called Friction Stir Additive Manufacturing (FSAM). The process combines the concept of friction stir welding to develop objects by joining them layer by layer. In research conducted by UNT’S CFSP, the process overcomes challenges that have plagued the additive manufacturing industry regarding metal-based additive manufacturing. FSAM has allowed for the welding of thinner metal alloy sheets, while still producing high-performance parts with improved mechanical properties and reduced welding defects. The emerging additive manufacturing technique is further highlighted in a publication by Hassan et. al.

The advantages awarded by FSW have seen its application in aerospace and other industries, as its strong weld properties supersede the need for fasteners. The solid-state nature of the process eliminates the need for melting, minimizing thermal distortion and residual stresses in the weld. The technology’s ability to weld dissimilar materials makes it possible to create multi-material and functionally graded structures. Additionally, the absence of high-temperature melt pools results in reduced energy consumption and fewer emissions, enhancing the process’ environmental sustainability.

The Research and Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

As advancements in material science, process improvement and tooling continue, FSAM has opened up a new frontier in manufacturing technology. As researchers and engineers continue to explore its capabilities and address its challenges, it is expected to play a significant role in shaping the future of advanced manufacturing.