Charles R. Goulding and Christopher Lee share their thoughts on one of Formlabs’ sample parts.

Formlabs, a titan in the realm of 3D printing, is shaping the future of manufacturing through its trailblazing innovations. Their commitment to excellence isn’t just limited to their advanced machinery; it extends to their unique approach of engaging stakeholders. By providing a complimentary 3D printed sample, Formlabs invites potential clients to witness firsthand the prowess of their technology. In this article, we’ll embark on a comprehensive exploration of the Formlabs experience—from the seamless ordering process and their forward-thinking marketing strategy to the remarkable quality of the 3D printed samples.

Order to Delivery

Formlabs has designed an intuitive and efficient ordering process, aligning with the demands of a fast-paced business world. Via their dedicated webpage, users can seamlessly navigate through an array of model options tailored to a wide array of business applications. After making a selection, the magic begins: the sample undergoes meticulous printing and quality checks, before being dispatched. The swift delivery not only attests to Formlabs’ operational efficiency but also serves as a tangible testament to their state-of-the-art 3D printing capabilities.

Strategic Marketing In today’s saturated market, Formlabs’ proactive and innovative marketing strategy sets them apart. Recognizing that businesses are more likely to invest in a product they’ve physically interacted with, Formlabs offers tangible samples. This genius move drastically reduces hesitation and skepticism, paving the way for businesses to make informed decisions. This tangible approach not only bolsters the potential of their 3D printers in the eyes of potential clients but also solidifies trust, laying the foundation for lasting partnerships.

Sample Quality Insights

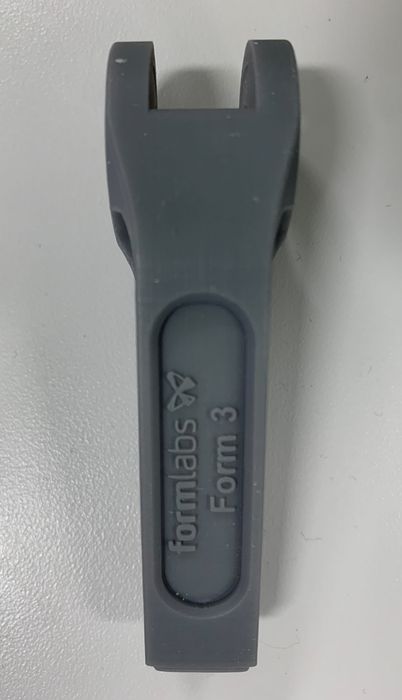

The provided sample is a testament to Formlabs’ commitment to advanced 3D printing solutions. Demonstrated in each precise curvature, edge, and detail, it showcases the consistent quality Formlabs delivers to its business partners. Notably, the “Rotating Arm” model was produced using the Form 3+ printer with Grey Resin. This resin is favored in the industry due to its adaptability for both standard prototyping and detailed design applications.

Beyond its visual attributes, the part exhibits a smooth tactile feel, combined with a lightness that doesn’t compromise its inherent strength. It offers high-resolution output, a smooth surface finish, and a refined matte appearance. The elimination of post-curing requirements further enhances workflow efficiency, marking it as a preferred choice for enterprises focused on both product excellence and operational efficacy. These characteristics, paired with Formlabs’ renowned print fidelity, position them as leaders in the 3D printing sector.

Conclusion

Formlabs has consistently demonstrated its dedication to advancing the field of 3D printing. Their strategic approach, which combines both marketing outreach and an emphasis on hands-on user experience, showcases their commitment to customer satisfaction and technological innovation.

By providing tangible samples of their capabilities, they not only highlight the remarkable quality and precision of their products, but they also build trust and confidence with potential clients and stakeholders. The complimentary 3D printed sample serves as both an effective marketing tool and a testament to the company’s leadership in the industry. As the realm of 3D printing continues to evolve, Formlabs remains positioned at its forefront, setting standards and pushing boundaries.