We had a look at one of Farsoon’s biggest metal 3D printers, the FS621-M.

How big is this machine? Just look at the image above: it’s so big it requires a walkway just to operate the device. It’s 6m long and 4m tall, and weights 8 tonnes!

What counts most, however, is the build volume. In this case the FS621-M’s build volume is a whopping 620 × 620 × 1100 mm. This makes it ideal to 3D print large metal objects for industry.

The FS621-M uses the familiar LPBF process, and uses a single 1kW laser. There is a variant machine, the FS621-M4, which uses four 500W lasers. This allows for greatly increased throughput as the lasers operate in parallel. The lasers can scan as fast as 15.2m/s, although the speeds must be moderated per job and material.

The FS621-M is accompanied by a powder handling unit, which provides the ability to sieve used powder and generate recycled powder for subsequent print jobs.

We took a close look at a couple of sample prints from the FS621-M, and were quite impressed with not only the size of the metal prints, but also the print quality.

Here is a cooling chamber for a rocket engine, printed in 316L stainless steel. While you can’t see it from the outside, this part includes a massive number of tiny millimeter-sized cooling channels inside the structure.

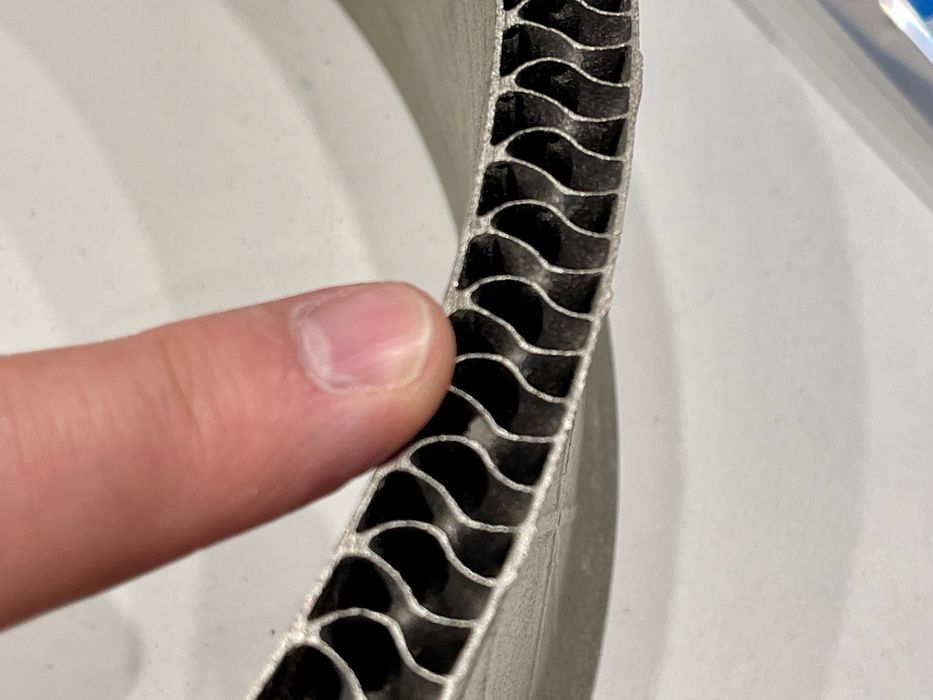

Here you can see the inside of a heat exchanger. The exchanger uses a “triply periodic minimal surface” approach.

Both of these complex parts were produced in a single print each, eliminating the need for part assembly. The single part approach also dramatically increases part reliability because there are no seams through which failures can propagate. In addition, there are no bolts and nuts to hold subcomponents together, greatly lightening the part’s weight.

Parts such as the above are possible to produce only in large build volumes, and that’s precisely what is offered by the FS621-M.

Via Farsoon