Charles R. Goulding and Preeti Sulibhavi look at two US companies at the forefront of construction 3D printing.

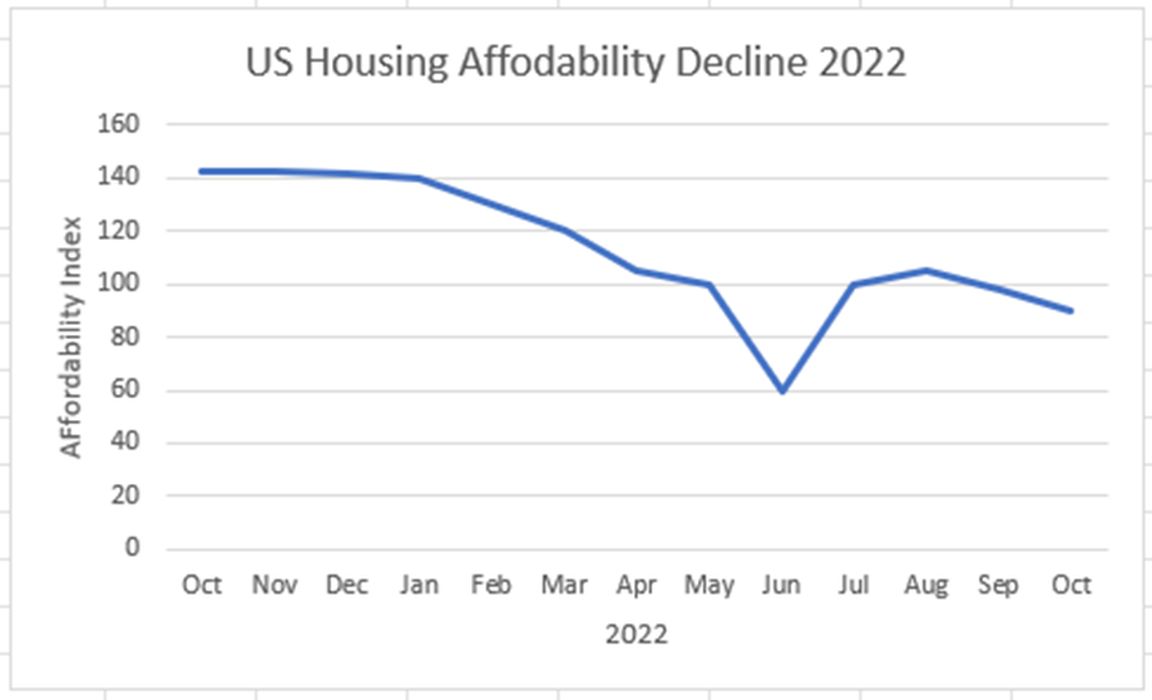

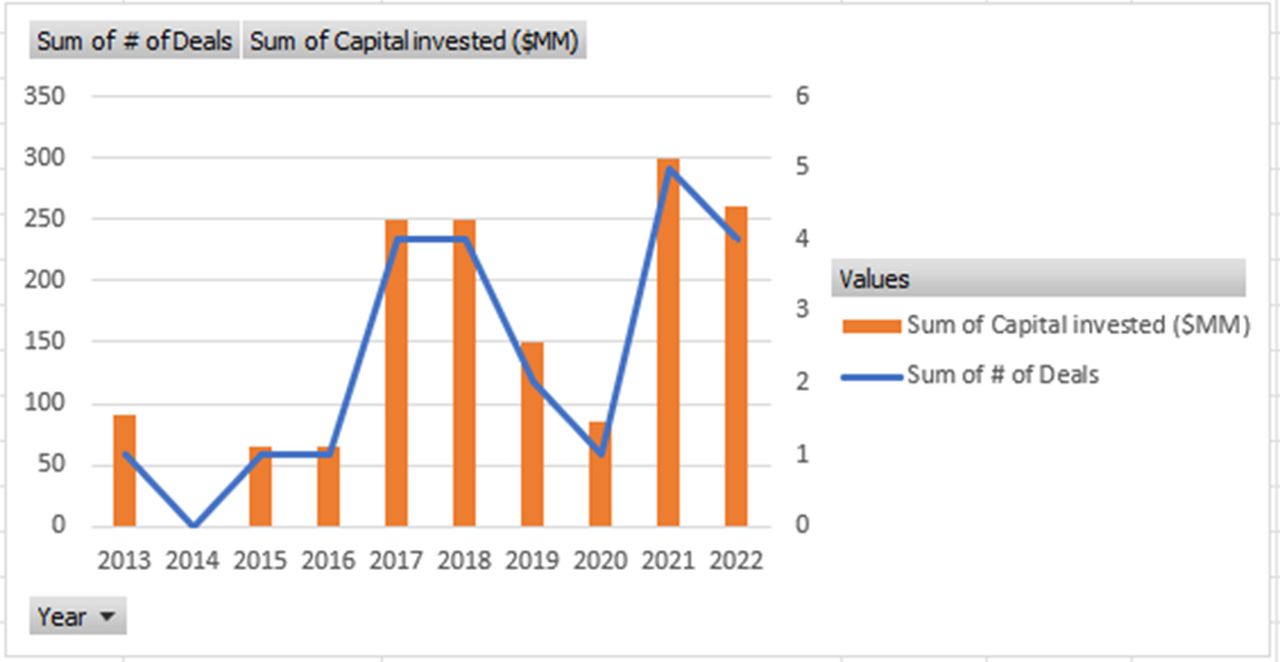

Affording a new home today is not the same as it was ten years ago, or even a year ago for that matter. The Financial Times’ Lex column, a highly respected financial source, had an interesting piece on the technical advancements of 3D printed homes, in its January 30th, 2023, edition. The column included two separate graphs showing the decline of US home affordability and the increase in venture capital in 3D printed homes.

The article covered two leading 3D home builders including Mighty Buildings and ICON, which together have completed over 100 3D printed homes.

The decline in US housing affordability (illustrated by the chart above) has spurred venture capital interest in 3D printing construction start-ups (depicted in the second chart). The indirect relationship between housing unaffordability and investment in 3D printed homes should not be a startling surprise. 3D printers can use a myriad of materials to create complex geometries and designs that create flexible yet durable structures. Homes, structurally require the same qualities.

Mighty Buildings and 3D Printing

Mighty Buildings prefabricates 3D printed homes, which enhances quality while minimizing raw material use and waste. Mighty Building homes are designed with versatility in mind and 3D printed, which is both cost and labor – effective.

Traditional, non-3D printed homes take an average of eight months to construct, whereas Mighty Buildings 3D printed single-family homes take half the time to assemble on-site. The pre-fabrication process is made possible because of their proprietary 60% recycled composite stone 3D printing material and the flat parametric walls maximize flexibility since they way 30% less than concrete and are 4 times more tensile and durable.

ICON and 3D Printing

As we have covered previously in a Fabbaloo story, ICON is helping to build 3D printed communities in Austin, Texas. In building the 3D printed home community, ICON found the advantages of using 3D printing to be like what Mighty Buildings discovered. Advantages of 3D printed homes include flexibility in design (particularly of walls) as well as less of a carbon footprint and wastage. ICON went one step further and is integrating robots to automate the process of home-building to reduce labor costs as well as injuries, to create a higher level of quality for homes that are “better in every way.”

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

While 3D printed homes can help start a conversation about US home affordability in recent years and what we can do to improve it, there is still much work to be done. Land prices often drive development cost and that is a fixed commodity.

We believe, that as 3D printers advance, particularly concrete 3D printing, that the structure of 3D printed homes can accommodate more complex designs to add levels to homes and possibly more enhancements. This is just the beginning.

Fascinating and interesting stuff.

I am interested in following developments and progress in this area