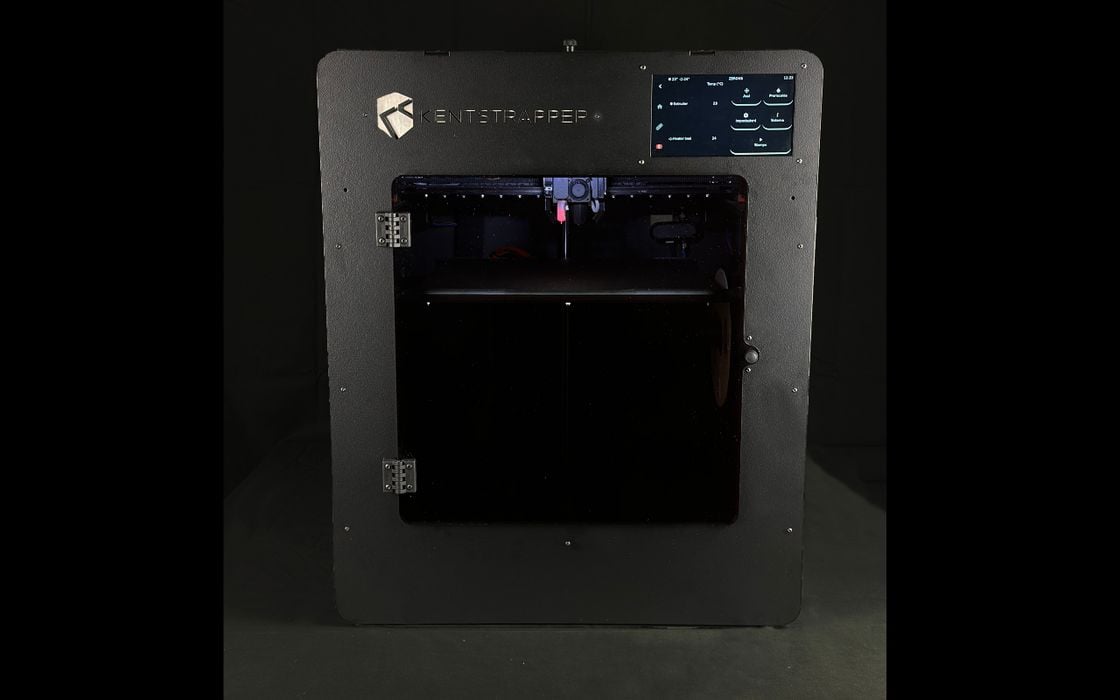

Kentstrapper introduced a new high-speed 3D printer, the ZeroHS.

Kentstrapper is an Italian company that’s been manufacturing desktop 3D printers for almost a decade. Currently they offer five different models, all using the FFF process. Their flagship model has been the “Zero”, but now it’s been made even better.

The company has developed new extrusion and motion systems for the ZeroHS that enable it to 3D print at extremely rapid speed, up to 400mm/second. The extrusion system is able to output 50mm3 of material each second, which is significant.

The ZeroHS is also equipped with a removable, flexible magnetic build plate that should provide for easy adhesion and print removal. The plate can be heated to 120C to enable use of a number of engineering materials.

The new motion system is based on the CoreXY design, where the build plate does not move in the X or Y axes, and the X & Y motors remain fixed. This enables very rapid movement, even when sharp directional changes occur.

The build volume of the ZeroHS is a healthy 320 x 320 x 320 mm, able to fit most parts. The build volume is not actively heated, but because it is enclosed it will capture stray heat from the heated print surface.

There’s only a single hot end and extruder on this machine, so you will not be able to 3D print with a different support material. Usually dual extrusion machines offer the ability to use soluble support to print highly complex objects, but that’s not the case on the ZeroHS. That said, Kentstrapper has implemented independent dual extrusion systems in the past, and perhaps a future version of the zero will use dual extrusion.

Meanwhile, Kentstrapper said the ZeroHS is able to 3D print these materials: PLA, PLA TOUGH, PETG, ABS, TPU, ASA, PC, and Carbon Fiber reinforced filaments.

The ZeroHS uses a 32-bit controller board, with a Raspberry Pi driving a 7” control panel for easy use.

As you might expect, the ZeroHS includes automated calibration. However, there is an interesting feature I hadn’t seen before: “Adaptive Calibration”. Apparently you can calibrate a specific zone on the print surface, perhaps for extra precision.

There are a number of sensors and encoders on the ZeroHS, and this allows for several automated procedures, including:

- Out of filament detection and recovery

- Detection of nozzle clogging

- Detection of under-extrusion

- Detection of no-flow

- Detection of power loss and recovery

The system is set up to be completely managed remotely through a web interface, which should assist its use in production environments. In addition to the WiFi interface, you can also operate the machine locally using USB sticks or SD cards.

Kentstrapper is to unveil the device publicly next week, but has not yet announced a retail price for the high speed 3D printer.

The ZeroHS joins an increasing number of high speed devices now hitting the desktop market. Perhaps soon devices of this speed will become a standard, but for now there are not many options and the ZeroHS is one of them.

Via Kentstrapper