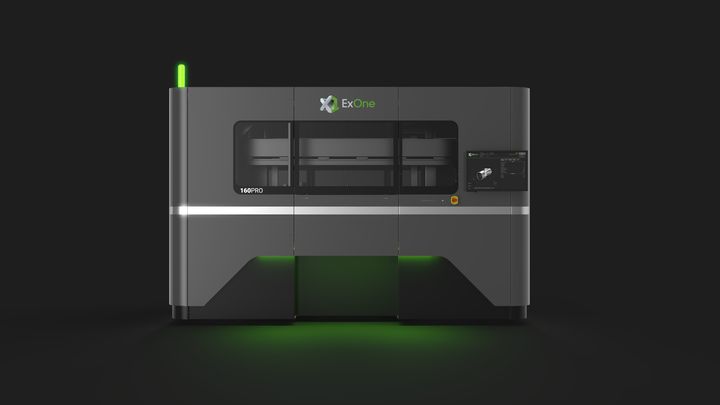

ExOne announced a new atmosphere-controlled version of their massive X1 160Pro metal 3D printer, opening up the possibility of using many different metals.

ExOne’s speciality is in binder jet 3D printing, in which materials are deposited from ink-jet like toolheads. They’ve parlayed this technology into various forms of 3D printing, including five different models of metal 3D printers, and three large sand 3D printers, which can produce molds for casting.

Now they’ve announced an atmosphere-controlled version. But why is that a big deal?

The answer is in the nature of metal materials.

It turns out that many metals are toxic, oxidizable and even explosive in fine powder form. These are obviously undesirable conditions, and thus systems using powdered metals must take steps to avoid disaster.

LPBF systems typically overcome the problems by using a completely sealed powder workflow, where the powder never is exposed to the air. Inside an LPBF 3D printer, the build chamber is usually filled with an inert gas like argon or nitrogen to displace oxygen. The oxygen could react with the metal powder particles to corrupt print quality, or worse, when exposed to the heat of a powerful laser, could cause an explosion.

Binder jet systems are somewhat less risky, as there are no sources of major heat, like lasers. Instead the material is deposited quietly and solidified later using various techniques.

They’ve even gained a patent for this process, “Apparatus for three-dimensional printing of reactive materials.” (PDF)

So why would ExOne want to sell an atmosphere-controlled 3D printer?

They seek the same result: displacing the oxygen. The oxygen could quickly “rust” some metal particles and that would surely reduce print quality. Print quality is of the utmost importance when using a 3D printer for industrial production, where each part must have the same high quality.

A useful side effect is that the controlled atmosphere also allows more directly control of chamber humidity, which can also corrupt prints. ExOne explains:

“A controlled atmosphere is essential for 3D printing of reactive fine metal powders, but it also offers other benefits, such as reduction of powder oxidation and enhanced powder dispensing and spreading through control of humidity. This update will smooth the way for high-volume production of aluminum, titanium, copper, and several other materials using binder jet 3D printing technology.”

And this is their real goal: certifying use of more types of metals in the X1 160Pro. Of particular note is copper, which is a metal that cannot easily be 3D printed by traditional LPBF systems due to its rapid heat conductivity. Fortunately, ExOne’s binder jet process does not involve significant heat, so copper should work pretty well.

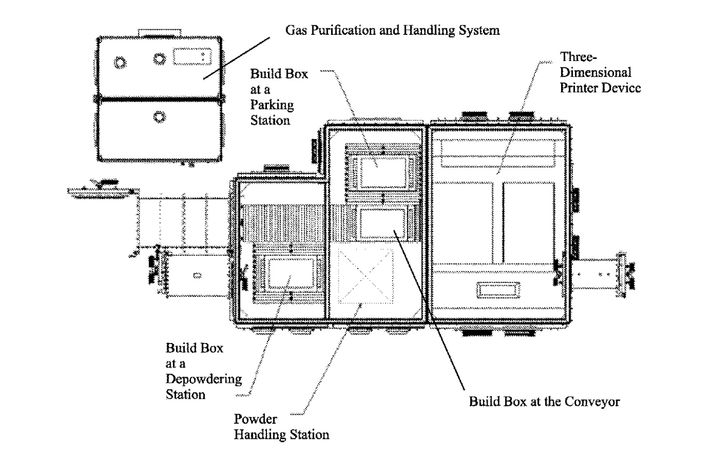

ExOne is also considering the entire workflow for using the X1 160Pro to produce metal parts:

“ExOne’s controlled-atmosphere X1 160Pro can be used with nitrogen or argon and will be paired with accessories and ancillary equipment also equipped with inert atmosphere features. These include a curing oven, powder conditioning system, depowdering station, and transport device for moving the build-box between process stages to ensure complete atmosphere control throughout the process.”

And:

“ExOne binder jet 3D printing technology is capable of processing 23 metal, ceramic, and composite materials, including a dozen single-alloy metals such as aluminum and titanium.”

This makes ExOne’s material portfolio among the largest in today’s 3D printer manufacturers.

Via BusinessWire and ExOne