ExOne may be the most committed and experienced metal 3D printer company in the world.

Since 1995, ExOne has dedicated itself to creating parts made from powdered metal and sand—and nothing else—using a proprietary binder jetting technology. As metal remains the first choice of engineers in their product designs and the status of plastic suffers from its growing environmental impact, metal 3D printing of parts is sure to be considered more seriously as a manufacturing option.

ExOne was displaying its latest 3D printers at AMUG 2021, recently held in Orlando, Fla. Its biggest competitors were not, playing safe during the pandemic. It was time for ExOne to shoot ahead of the pack.

Metal Heads

Due to its focus on metal, ExOne has had more time to deal with—and fix—the issues of printing in metal—issues that are considerable and potential deal breakers for engineers who staked their reputations on metal parts formed by time-worn traditional methods. Forging, casting and machining have withstood the test of time. They provide precision, confidence, low risk … qualities that engineers hold dear. Those parts can be counted on; they won’t fail. Introducing a new process (3D printing of metal) can introduce doubt in many words (voids, uneven powder distribution, melt pools, porosity, distortion…) and problems you never had.

Engineers demand that any new process be put to the test. Accepting parts made from powder or wire—parts to be thrust into space, and used in military vehicles, automobiles, human bodies … any exacting environment—is not automatic. The concept of producing a part by building it bit by bit—rather chipping away at a block of material—does make sense immediately. The part will cost less in terms of energy, it will use less material, and so on. But expecting that material to turn solid to powder, and then back to solid again, and be the same, is still wishful thinking. We wish we could transport like in Star Trek, too.

ExOne is introducing a printer that can form parts from 6061 aluminum alloy powder. Aluminum alloy 6061-T6 (the suffix designates hardening) is favored by the aerospace industry.

How Much?

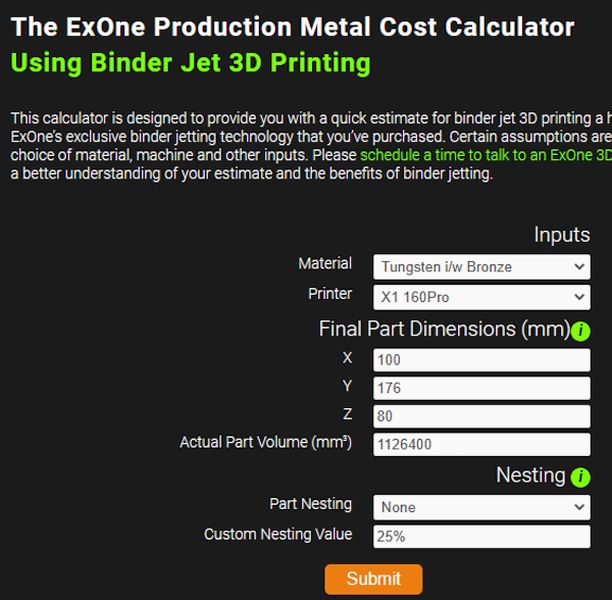

What will it cost to make this part with a metal 3D printer is the burning question for product engineers testing the waters of powdered metal—and one that can be answered quickly with ExOne’s part estimator. The part estimator will instantly estimate how much a 3D-printed metal part will cost for a material. Oh, you don’t have a metal 3D printer available? If $2 million for a metal 3D printer and the space it will need to occupy is too much for you, ExOne can quote you a price to make the part and ship it to you.

Read more at ENGINEERING.com