It seems that Essentium could soon join the ranks of companies producing metal 3D printers.

Metal 3D printers are in high demand due to the gradual transformation of certain industries towards additive approaches. In particular, the aerospace and automotive sectors have adopted AM as a standard approach for making certain types of parts for production.

While most 3D printers are used for prototyping purposes, Metal 3D printers tend to be used for the production of end-use parts and products. That’s due to the material: metals are the same whether prototyped or made for end-use, whereas many prototyping materials might not be the same as used in the end product.

As a result of this demand we’ve seen many companies enter the metal 3D printing space with different approaches. Desktop Metal and Markforged are two notables, but there are many more.

Now it appears Essentium may join them.

The company has up to this point focused on polymer solutions using collaborative approaches for production parts with clients.

In a discussion this week with Essentium CEO Blake Teipel I learned that the company is indeed working on a metal 3D printing solution.

They are not at the point where they are ready to announce any details, but it seems that they are well along the way, and a formal announcement could be in the near future.

Teipel could not tell me much about their new metal 3D printing process, but it seems that it is definitely not going to be using the standard LPBF approach. Teipel insisted their process will be safe and much easier to handle because it won’t use powder.

Powder-based metal 3D printing processes can provide high resolution results due to the particle size, but this also creates many challenges. Many metals are toxic when inhaled or even explosive if exposed to oxygen. This means that typical powder-based metal 3D printing systems must take extraordinary measures to isolate the powder as it passes through the system. This is all quite expensive, as you might imagine.

If Essentium’s approach is indeed not using powder, then it could be far less expensive than competing LPBF systems.

It may be that Essentium’s metal process is similar to several “cold” processes where a polymer binder is used to print “green” objects. These undergo subsequent debinding and sintering steps to finalize the part into solid metal, although the dimensions shrink a bit in the process.

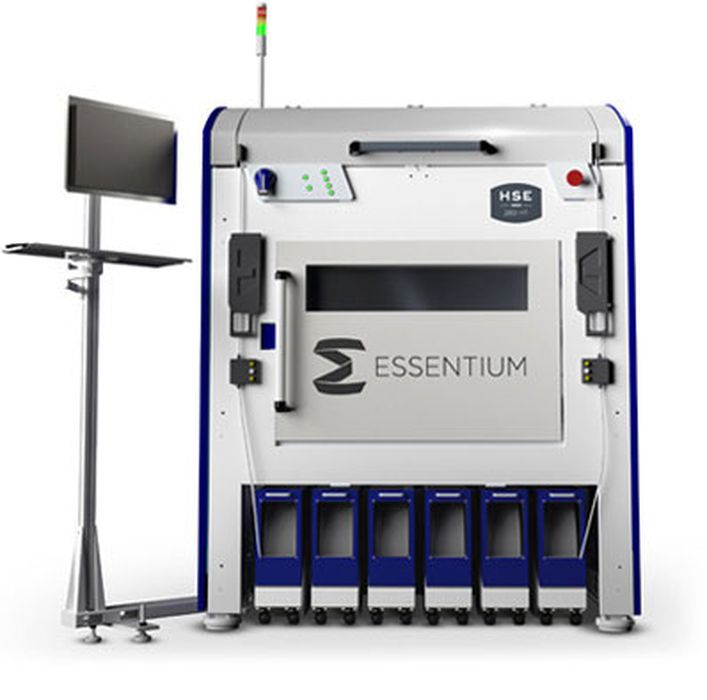

One possibility is a modification to their popular filament-based 3D printers, the HSE series. These devices 3D print filament at very high speed and with great accuracy. It might be possible to 3D print metal-infused filaments to create these green parts by playing with the extrusion system, nozzles and thermal controls.

If so, this would put them in competition with Desktop Metal, Markforged and several others offering this style of metal process.

We do know that Essentium has been working very closely with a number of clients in the US Department of Defense, and it could be that they may have been encouraged to develop this process through those relationships. That might suggest they have some initial clients already in mind, and a possible market to address.

I’ll be looking for further news on this metal 3D printing process.

Via Essentium