Essentium’s in-house 3D print service is up and running.

The company has produced high speed industrial 3D printers for quite a few years now, so this is a different angle on using their equipment. Instead of purchasing a machine, a customer could order parts to be produced by Essentium’s internal service.

They call it “EPOD”, or “Essentium Printing On Demand”, a “polymer to part” service. They say they can provide quotes within 24 hours for most materials, but it could take longer for more complex materials scenarios.

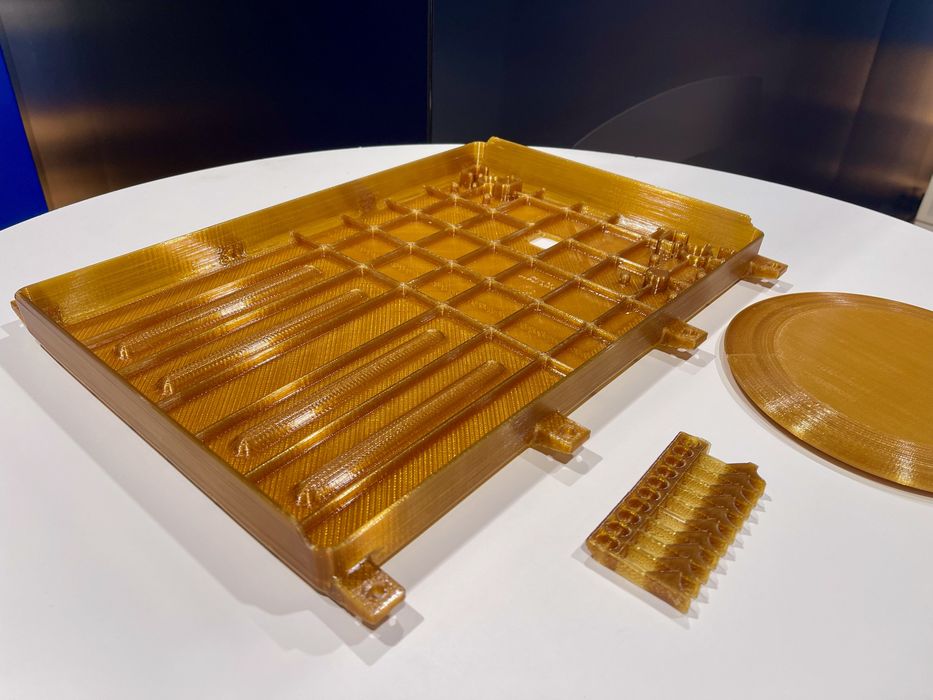

For example, they can even create a unique custom material for clients if required. Above is a unique material I’ve never seen previously: a flexible PEI mix.

EPOD Use Cases

Why establish EPOD? It turns out there are quite a variety of reasons for doing so.

One is “proof”. The idea here is that a company considering purchasing Essentium equipment might require a bit of testing before committing. This could be done by simply ordering parts that are produced on the same equipment and with the same materials through EPOD. This allows the client to examine the parts and ensure they are what is required for their company before purchasing equipment.

Another use case is “overflow”. In this scenario a customer using Essentium equipment and materials finds they have orders that exceed their capacity. They could simply offload excess work to EPOD for production in parallel with their own operations. This effectively makes companies with Essentium equipment “bigger”, as they don’t have to plan for as high a peak capacity.

EPOD Benefits

One more angle to this approach is certification. Many of Essentium’s clients are from the US Department of Defense, and as you can imagine there are a ton of regulations to be dealt with when producing parts. I got the impression that EPOD could provide some of that capability.

This means that an EPOD customer could potentially benefit from at least some aspects of DoD-level operations merely by ordering parts from EPOD. In other words, they might be able to leverage Essentium’s regulatory efforts.

A print service also allows Essentium to upgrade and tune the equipment in the background without causing customers any worries. In a customer-based print operation there could, for example, be downtime while upgrades take place. That scenario wouldn’t occur with EPOD. It also means that the EPOD equipment is more easily kept up to date with the latest models, firmware and other tweaks, and customers don’t have to do them at all.

Finally, there is another benefit, but this time for Essentium. The presence of EPOD means they must have staff running their own equipment in the same way that their clients do. This will almost certainly provide Essentium with new insights into the operation of their machines. They’ll discover issues and inefficiencies, and then be able to rectify them through updated customer procedures, machine design tweaks and other approaches. In other words, it should make Essentium equipment better over time.

There are quite a few benefits for everyone when a 3D print service is used, so I’m surprised more 3D printer manufacturers don’t do this. Some do, and there are even some newer companies that only provide services and never sell equipment directly to customers. Could services be the way of the future?

Via Essentium EPOD