Essentium announced the availability of a new high temperature material for their equipment, PEKK.

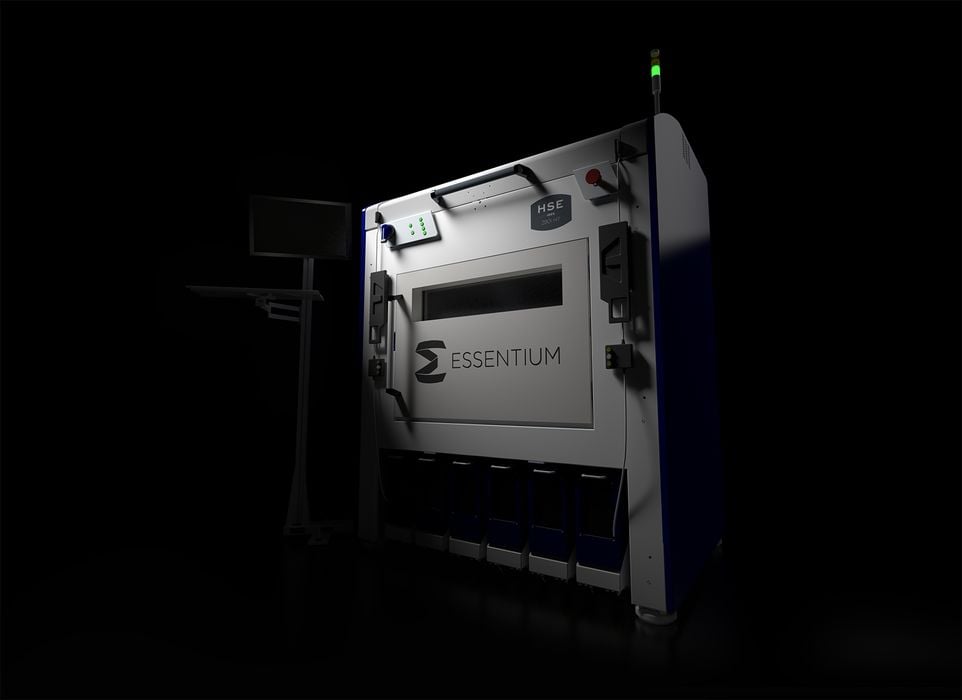

The company is following up on their announcement last week of their new HSE 280 HT 3D printer, which provides what could be the very first commercial implementation of truly independent dual extruders.

While the independent dual extrusion system is of great interest, there’s also that “HT” in the machine name. This, of course, stands for high temperature, and the machine is capable of 3D printing higher temperature materials.

These “HT” materials are of increasing interest to industry for several reasons. First, they tend to be much more chemical resistant than more commonly available 3D printing materials. That allows them to be used in more challenging environments.

More importantly, high temperature materials can sometimes be substituted for metal parts. While this may at first seem a bit crazy, it all depends on the temperatures of the application environment. There are many cases where operating temperatures are high enough to soften lower-temperature 3D print materials, but not so high as to soften the high temperature materials.

This allows a machine designer to swap in a much lighter-weight thermoplastic part and take out a heavyweight metal part. For many applications, the weight saving alone is more than sufficient to justify the cost of the part.

Today Essentium announced the availability of Essentium PEKK, an “ultra polymer” that not only offers high heat resistance, but also increased chemical resistance. Essentium partnered with Arkema to produce the new material, which is based on Arkema’s 6002 Kepstan resin.

Essentium explains some of the advantages of Essentium PEKK:

“PEKK shares most of the performance attributes of PEEK but has a lower crystallization rate and can therefore be treated as an amorphous polymer. This means it is less affected by the cooling process once the part is 3D printed, thereby minimizing warping. PEKK maintains the flame smoke toxicity ratings for FAR (Federal Aviation Regulations) compliance while offering improved resistance to chemical attack compared to PEI materials. PEKK has an extrusion temperature between 340 and 400°C.”

The new material joins previously announced high temperature materials that include ULTEM, PEEK and a high temperature nylon series.

Essentium has long had a strategy of working directly with clients to solve their challenges, and one way of doing that is to provide material flexibility sufficient to meet their application demands. By adding more materials to their catalog, Essentium should enable an increasing number of manufacturing applications on their equipment.

Via Essentium