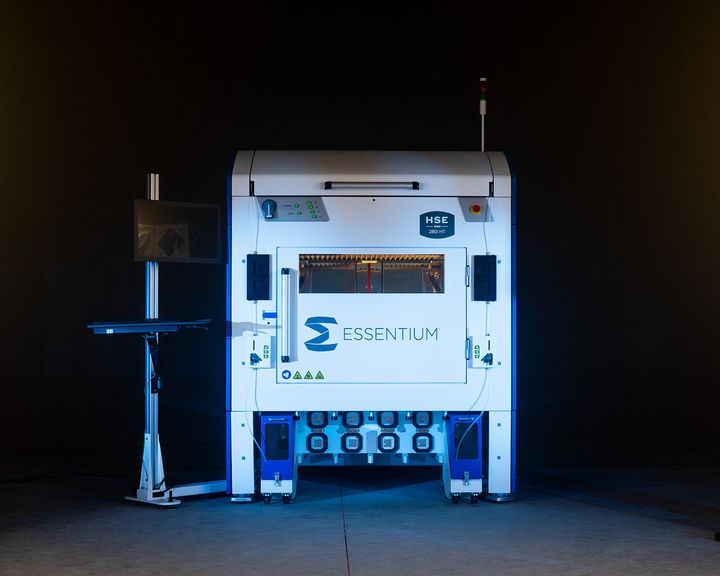

Essentium today announced a new and rather interesting 3D printer, the HSE 280i HT.

This device inherits many of the properties of the previous Essentium equipment, including their very rapid print speeds. Essentium leveraged their knowledge of high-speed electronics manufacturing into the designs of their 3D printers, which allow print speeds of up to an astonishing 500mm/second — which I’ve seen with my own eyes.

The big innovation on the HSE 280i HT is the IDEX feature. “IDEX” is an abbreviation for Independent Dual Extrusion, a way for the 3D printer to use more than one material at a time. It’s the most advanced approach for dual extrusion yet seen.

Earlier methods of dual extrusion involved some of these techniques:

- Bolting a second extruder and hot end to the first toolhead — but that makes the toolhead very heavy to move, and allows drips from the unused nozzle

- Using a single-nozzle, two-filament hot end — which works but requires massive material waste to purge material at each switch

- Swapping toolheads during 3D printing — which is fast but requires a great deal of mechanical elements that could fail, and does not allow more than one stream of material at a time

Eventually, “independent” extruders appeared, but often these were simply second extruders mounted on the X-axis that could move on that axis independently. However, other axes were shared with the rest of the machine.

Essentium says their approach is the first “true” independent dual extrusion system. They explain:

“Unlike other IDEX 3D printers on the market, the HSE 280i HT 3D Printer features true independent dual extruders whereby each head is fully independent on both the X and Y-axis. This enables manufacturers to speed time to industrial-scale production of parts, even for complex geometric shapes, while significantly reducing post-processing costs.”

While these extruders apparently share the Z-axis, they otherwise can operate entirely independently.

This opens up a number of new 3D printing modes. Some examples:

- Duplicate prints: both extruders build identical objects, effectively doubling machine throughput

- Mirror prints: each extruder prints a mirrored version of an object, enabling one to produce two halves of an object in a single print job in half the time

- Dual prints: both extruders print different objects at the same time, doubling machine throughput

What is not yet clear is whether Essentium has achieved the elusive holy grail of dual extrusion 3D printing: the ability for two toolheads to work independently on a single object simultaneously. This would double the print speed, if possible.

That is a complex software problem to solve, but in discussions with Essentium long ago I received some hints that this might have been considered. Could it be that they have figured this out?

The new 3D printer also includes an unusual heating system. Essentium explains:

“Differing from most FFF processes that rely on a heated build chamber, the HSE 280i HT 3D Printer uses a multimodal heating method designed to heat the part, eliminating the need for manufacturers to wait for the chamber to heat up to start printing.”

Essentium is targeting the HSE 280i HT for industrial applications, and has partnered with LEHVOSS Group to develop a new PP-CF material for use in the device. This material seems to open up the use of 3D printing for silicone and urethane casting applications.

Essentium CEO Blake Teipel said:

“The manufacturing industry is increasingly moving toward a leaner and more agile future enabled by AM. This is the beginning of radical change, where billions will be saved through new economic and production models. But this change requires continuous and unrelenting innovation to be able to do things not done before, to make parts that haven’t been made before – and manufacture things that haven’t been manufactured before. This is our goal with the launch of the industry’s first true IDEX machine– we believe the HSE 280i HT 3D Printer is a game-changer giving manufacturers the ultimate machine tool to 3D print at scale.”

I’m quite interested to get a closer look at the new HSE 280i HT’s IDEX system.

Via Essentium