Epson announced a new 3D printer with an unusual extrusion mechanism.

The new as-yet-unnamed device is intended for small batch industrial use and leverages technology from the company’s well established 2D operations.

The company is well known for their consumer products, most notably 2D printers. But in fact Seiko Epson Corporation is a massive conglomerate providing many other consumer and industrial products, including projectors, robots, wearables and other devices to healthcare, manufacturing, and information technologies.

I am not aware that the company has produced previous 3D printers, but it’s not surprising that they have done so. Many other large companies producing related technology equipment have added 3D printers to their product mix, with examples being Xerox, HP, and Canon. Epson has merely joined that group.

Smartly, they’ve chosen to go the industrial route where the majority of the money is to be made as companies gradually shift their equipment towards additive processes.

We don’t know a lot about the new machine, as Epson declined to even provide it a name, nor the unusual 3D printing process it uses. There were no specifications provided, but it appears they will show the machine this week at a trade show in Japan. But we do know some things.

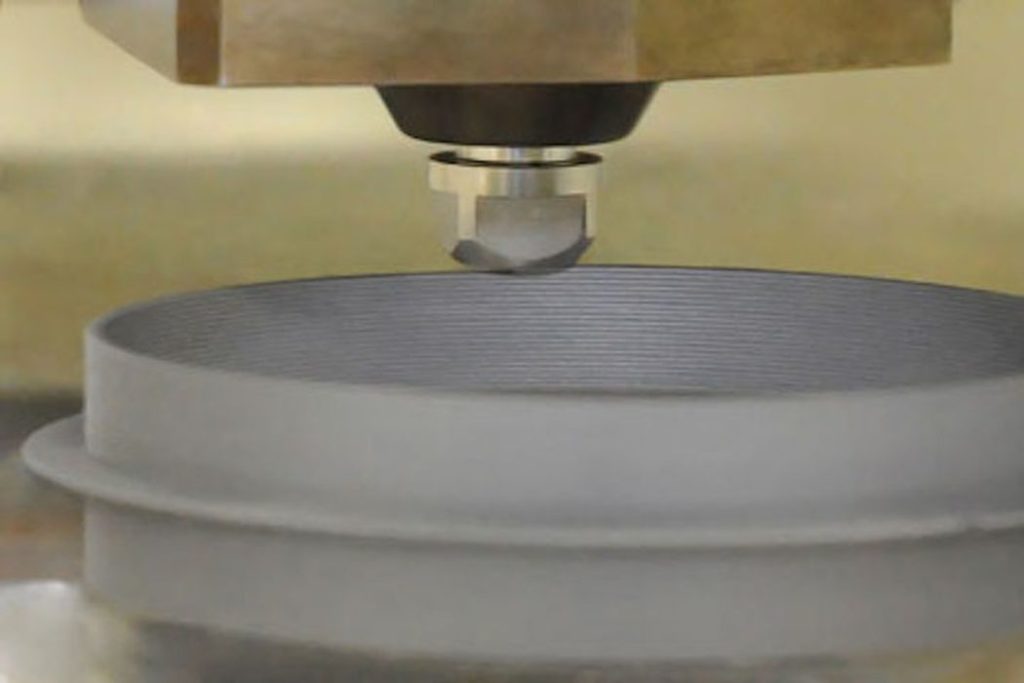

The machine uses a “flat screw” extrusion process. They explain:

“Epson’s newly developed 3D printer employs a unique material extrusion method that is achieved using a flat screw (an inline screw with a flattened configuration) like that found in Epson’s precision injection molding machines. This extrusion method enables the printer to be used with a variety of common third-party materials, such as resin or metal pellets, which are generally available at lower cost than other materials, environmentally considerate biomass pellets, and PEEK materials, which can provide high heat resistance.”

In addition, they seem to have developed an interesting thermal system that could provide far stronger bonds between extrusion layers, which is the unusual knock against additive parts. They explain their thermal approach:

“The amount of material injected is precisely controlled by regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed. The temperature at the surface of a piece being printed must also be controlled in order to obtain the required strength. Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy. This 3D printer is thus engineered to manufacture strong, accurate objects with commonly available materials, facilitating printer use in the production of industrial parts for final products.”

Epson intends on using the device internally to work out the bugs before they officially launch the machine for manufacturing use.

The entry of Epson to the industrial 3D printing market is interesting, but as they are a new player on the scene they will have a great deal of work to catch up to the existing players. They’ll have to set up relationships with manufacturers, demonstrate the feasibility of their technology and prepare a compelling offer for buyers.

It will be a challenge for them, but they have plenty of resources and another option is always welcome.

Via Epson