We recently saw a safety demonstration by BOFA that showed the ability to clear dangerous particles away from 3D printers.

The silent danger of desktop 3D printers is their emissions, and this occurs with both resin and filament machines.

Resin equipment usually has a vat of resin that slowly evaporates into the air, releasing potentially toxic particles. I always strongly recommend using exterior ventilation or other filtration solutions whenever operating resin 3D printers.

FFF devices heat the filament, and by doing so tend to begin release of airborne particles. These nanoparticles are composed of the same material as the filament, and can be toxic or irritative. Some materials, like ABS, emit more particles than other materials.

The nanoparticles might be what’s called a “VOC”, or volatile organic compound. These are a long list of substances known to cause biological problems, and it’s important to avoid exposure to them.

The problem is that you can easily breath them into your lungs where they will remain forever and potentially cause problems in the future. Unfortunately you cannot see these particles as they are too small.

This is where BOFA, a manufacturer of filtration solutions, provided a visual demonstration.

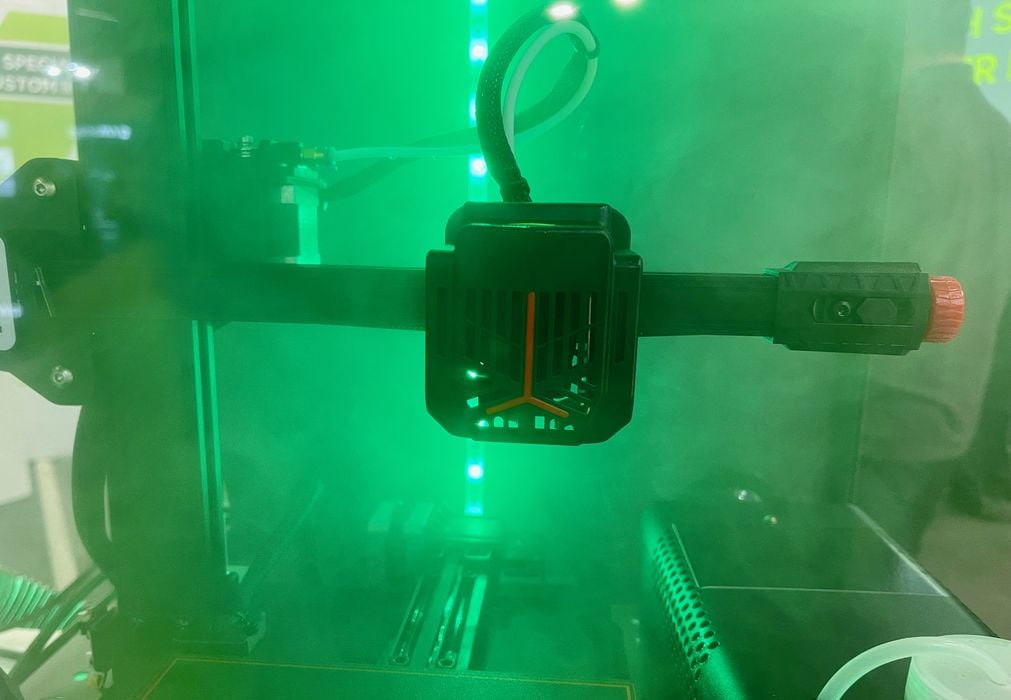

At top you can see the interior of a typical FFF 3D printer with a sealed enclosure. For the demonstration BOFA puffed some fog into the chamber to provide a visual reference for the normally invisible particles. The fog particles vastly outnumber the particles emitted by a normal 3D printer, but demonstrative.

When the enclosure was filled with fog they switched on one of their dedicated 3D printer filtration solutions. Within a moment or two, the chamber was entirely clear and free of fog. One can easily imagine that if there were nanoparticles in the chamber, they’d be gone, too.

That was a powerful demonstration of what’s possible in the world of 3D printer filtration, and a strong reminder that we should all ensure our 3D printers are properly ventilated.

BOFA provides many filtration solutions for industry, but is one of the very few companies that has a specific product line dedicated to 3D printers. Currently they offer four models, mostly focused on filtration capacity:

- 3D PrintPRO 2 – low cost unit

- 3D PrintPRO 3 – tabletop unit

- 3D PrintPRO 4 – for large format 3D printers

- AM 400 – premium solution

These include both HEPA and particulate filters that can remove VOCs and nanoparticles. There are also a series of adapters to enable connection to popular devices.

The AM400 is unique as it has to integrate with metal 3D printers, which must use inert gases in their build chambers to avoid oxygen contamination. The AM400 can securely connect to these systems and operate with inert gases instead of plain air, as their other systems do.

Safety is often a forgotten aspect of 3D printing, where eyes are usually on printer specifications and material properties. Eyes should also be on material safety sheets and ensuring printing is safe for everyone involved.