Researchers have developed an unusual 3D printable gel that is not only metallic, but has 4D properties, too.

Conductive 3D print materials have been around for quite a while, and while they exist, they generally are not the greatest. The most often encountered issue is that the conductivity is relatively low and thus not suitable for many applications. They may be “conductive”, but the real question is “how conductive?”

The new approach is quite unique. Instead of mixing conductive particles in a typical 3D printer material, the researchers simply mixed microscopic copper particles with plain water, and combined that with a “small amount of indium-gallium alloy”.

When this mixture was stirred, the copper particles stuck to each other and effectively created a gel. Researcher Micheal Dickey explains:

”This gel-like consistency is important, because it means you have a fairly uniform distribution of copper particles throughout the material. This does two things. First, it means the network of particles connect to form electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.”

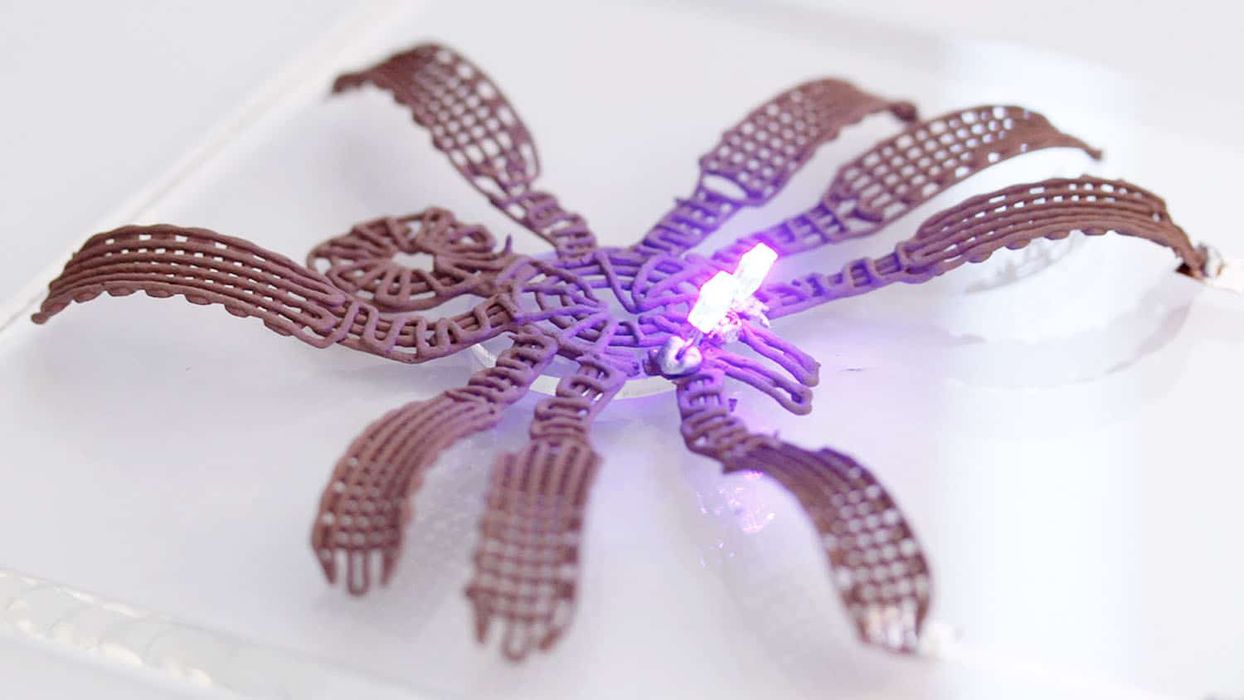

The gel was also of sufficient strength to be 3D printed, and that’s exactly what was done.

The resulting extrusions are wet, as you might imagine. As they dried, they hardened and became conductive paths for electricity.

However, the researchers observed another unusual property of this substance: the extrusions would distort as they dried. Even stranger, the amount of distortion would change as the drying temperature was raised. They found that they could reliably predict the ultimate shape of the dried extrusion based on the applied drying temperature.

You can see how this works in this short video:

How conductive are the extrusions? It turns out they are 97.5% made from copper, so they are extremely conductive, far more than typical conductive 3D print materials.

This conductivity suggests there could be new 3D printable applications enabled by the new gel. What could they be? We don’t know yet, but it seems that the researchers are quite open to discussing possibilities with those in the industry. That will ultimately lead to commercialization of the metallic gel and just perhaps the ability to 3D print fully functional electrical traces embedded within objects.