We had a chat with the nice folks from Ulendo.

You probably haven’t heard of Ulendo, as they are still a very small startup company. Their focus is to optimize the surface quality of 3D prints using a unique method of momentum compensation.

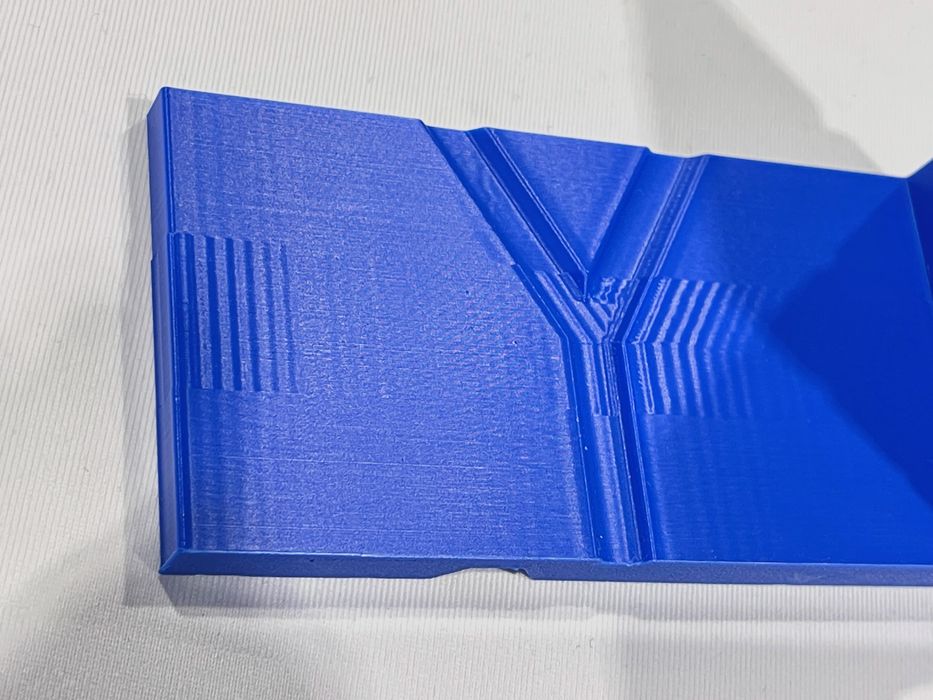

Basically, their software is able to eliminate “ringing”, a good example of which is shown at top. These patterns are generated during a print job as the toolhead wobbles when it changes direction at higher speed. The result is these echo-like patterns that appear like a repeating shadow of a structure. They are particularly evident at corners, and increase as print speed rises.

Ulendo’s software interprets the motion instructions in GCODE and makes adjustments to compensate for the momentum when a directional change is about to happen.

Momentum compensation is fast becoming a requirement for any high speed FFF 3D printer. It’s easy to make a machine run faster, as all you need to do is type a larger number into the print speed box in the slicer. But without proper momentum compensation, you’ll get a lot of ringing.

Ulendo tells us they are now rolling out their software to a variety of unnamed OEMs, which will no doubt include in their upcoming 3D printer designs. These will apparently be announced a bit later, as they must coordinate with the OEMs. We’re told there are five OEMs in play at this time.

One very interesting fact we uncovered was that the Input Shaping feature that suddenly appeared in a recent release of Marlin 3D printer firmware was in fact based on Ulendo’s software! This explains how Marlin was suddenly able to catch up to Klipper with that increasingly critical feature.

It also seems that Ulendo is not content to focus just on the FFF momentum issue. According to their representatives they are now looking at a completely different market: metal 3D printing.

There are plenty of challenges in the highly complex world of LPBF metal 3D printing, including the tendency for prints to warp and crack. These can ruin the expensive prints.

Ulendo believes their compensation approach, at a high level, is sufficiently similar to the metal issues that it may be applied there as well. In other words, we should at some point see a LPBF solution emerge from Ulendo that could dramatically increase the quality and reliability of metal 3D prints.

Meanwhile, their technology is going to be a huge part of the expected wave of high speed FFF 3D printers that will be announced over the next year.

Via Ulendo