Is there an easy way to tell whether a 3D printer is not for you? Yes, there are several.

With hundreds of different desktop 3D printers now available on the market at very low prices, it’s become quite difficult to choose between them. In the price range of US$200-700 you will find some very good devices, but also some not-so-good devices.

With all the new machines coming out there is a tendency for 3D printer operators to upgrade, often when the older machine is still serviceable. These used machines are now flowing around the market as well, and those new to 3D printing may encounter them.

Frequently these machines don’t carry well-known brand names, so it’s hard to know whether a machine is “good” or not. Don’t worry, we’ve put together several tips for you to look for in order to determine whether a given 3D printer is probably not a good bet.

That said, a quick disclaimer: there are always exceptions, so these are not hard and fast rules. Consider them as data points when making a purchase decision.

Further, the increasingly low cost of new and very capable machines poses a good point of comparison for not-quite-new equipment: if you can buy a better new machine at the same price as an older machine, they why do so? Prices continue to drop, and pricier older machines marked at a “discount” may in fact be as expensive as new machines.

Let’s take a look at some signs a 3D printer may be questionable.

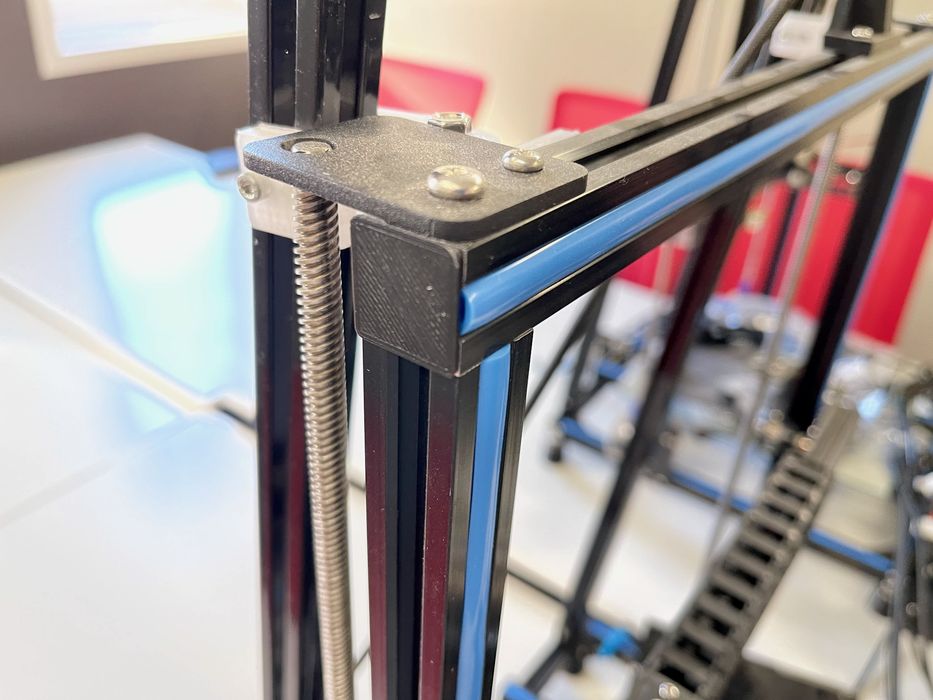

Thin Frame

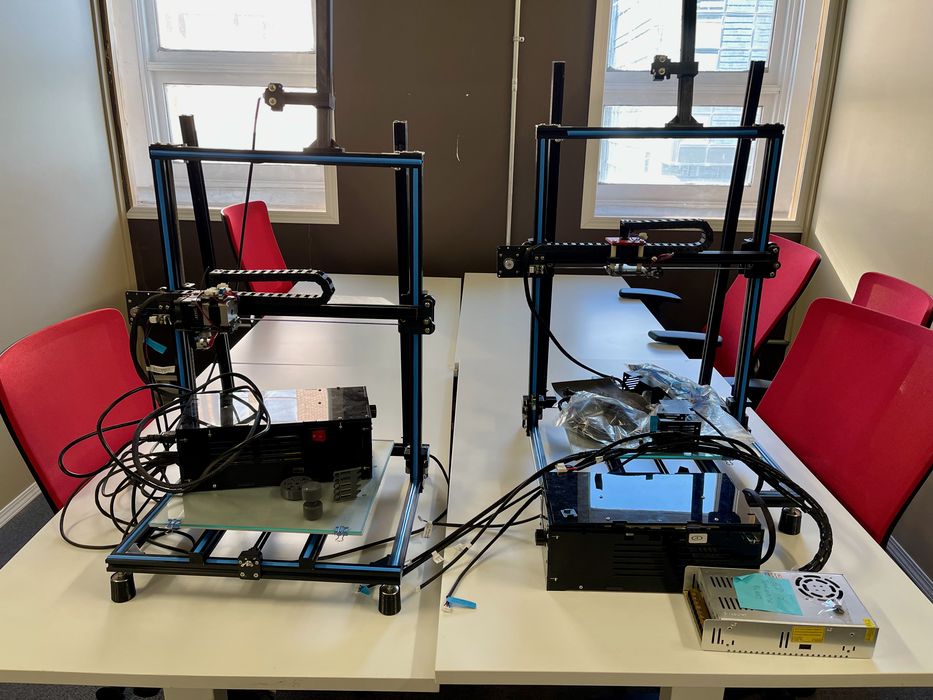

Early desktop 3D printers were made from thin aluminum extrusions in an open gantry form. These slim extrusions supported the motion system, but there were plenty of issues. See the image above for an example.

The lack of robustness meant the motion system had a lot of “play”, leading to low quality prints as the toolhead wobbles around due to lack of rigidity. This effect is particularly bad for larger build volume units.

If you see a desktop 3D printer with thin extrusions, it’s probably not going to be a very good machine.

External Power Supply

Today’s desktop FFF 3D printers typically have the power supply integrated into the base, and only a normal power cord is required to plug it in.

However, less sophisticated machine tend to have bulky external power supplies that must sit beside the 3D printer or on the floor. While functional, it shows a notable lack of innovative design: they didn’t bother to accommodate the power supply and just left it outside for you to deal with.

Cabling Circus

There are lots of cables in a 3D printer because the controller board must communicate with:

- X-axis stepper motor

- Y-axis stepper motor

- Z-axis stepper motor(s)

- Extruder

- Hot end heater

- Hot end thermal sensor

And more. Properly designed systems will integrate these cables in a way that is unobtrusive, but poorly designed machines simply ignore the cables and they are loosely draped all over the machine. This can in some cases even cause problems where the cables can tangle with the motion system.

At the very least the cables should be neatly tied down or corralled in some way. If not, you have a machine where the designers didn’t care too much about cables.

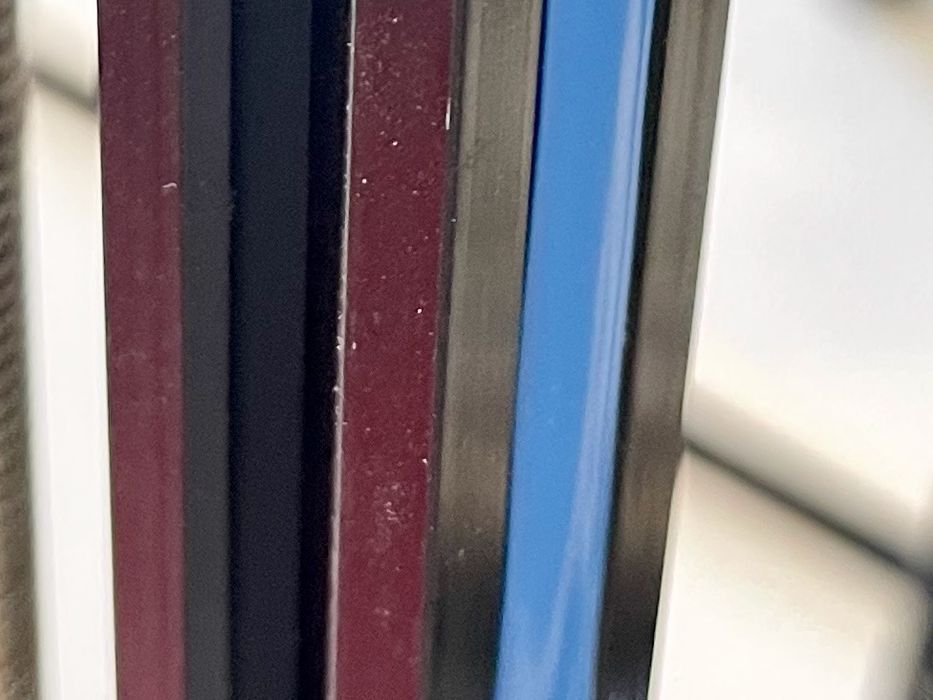

Stripes

I haven’t seen this so much recently, but in past years some 3D printer manufacturers would include lengths of plastic that could be inserted into the (typically thin) aluminum extrusions. This, I guess, provided a bit of color to an otherwise dull machine.

But it also is an indication that this is an old machine where designers focused on easy ways to make the machine supposedly look better instead of making it function better. Generally, machines with stripes are not so good.

Missing Control Panel

How can you not have a control panel? Actually, you don’t need one: the early 3D printers were run directly from a USB-attached PC, which became the “control panel”. This was a way to reduce the cost of manufacturing the machine by eliminating an expensive component, but it’s also an indication that the machine is too old and lacking basic function.

Wood

I haven’t seen one of these in a while (except those in my personal 3D printer museum), but some early 3D printers were actually made of wood. These were typically laser-cut pieces that the operator would assemble. Inexpensive to produce for the manufacturer, but more effort for the operator to assemble.

These wood pieces held the machine up, but really provided little in the way of rigidity, which will result in poor quality prints. If you see a machine made from wood, it’s either a prototype or a machine you probably don’t want to use.

No Spool Holder

The spool holder is now a standard feature on desktop FFF devices, but it didn’t use to be. I recall buying “lazy susan” turntables to hold spools long ago, but now it seems inconceivable not to have a spool holder.

If you see a machine without a spool holder, run away.

No “Advanced” Features

A typical inexpensive desktop FFF device these days includes features like a filament-out detector, power-fail recovery, automated (or at least assisted) leveling and more. At one time in the past these would have been considered “advanced” features, but nowadays they are standard and provide great benefit to the operator.

If you see a machine without these features, it’s probably a machine you should avoid. Even the lowest cost machines of today include at least some of these advanced features, so there’s no reason to buy a 3D printer that doesn’t have them anymore.