I follow many 3D printing companies, but there are a few on which I’m keeping a close watch.

Over the years I’ve seen many 3D printing companies emerge, grow and thrive — or die. After a while there seems to be some common characteristics that indicate the potential for future success, and that’s what I look for when speaking with new companies entering the space.

There are plenty of companies in the 3D print space, be they device manufacturers, materials providers, software players, hardware makers or services. New companies seem to appear each week, but by and large most are most likely facing a significant struggle to compete in a market where they are not significantly differentiated.

That’s the key to success in the future: you have to do something very different from others, and make sure it’s something that is truly beneficial. Successful companies should have a large potential market, and be sufficiently funded to attempt reaching it. Finally, good management is also a mandatory requirement, where practical moves lead the venture to growth and success.

Who are the companies I’m watching because they have some or all of these characteristics? Which companies are likely be a lot bigger in the near future? Look no further, my list is below.

Teton Simulation

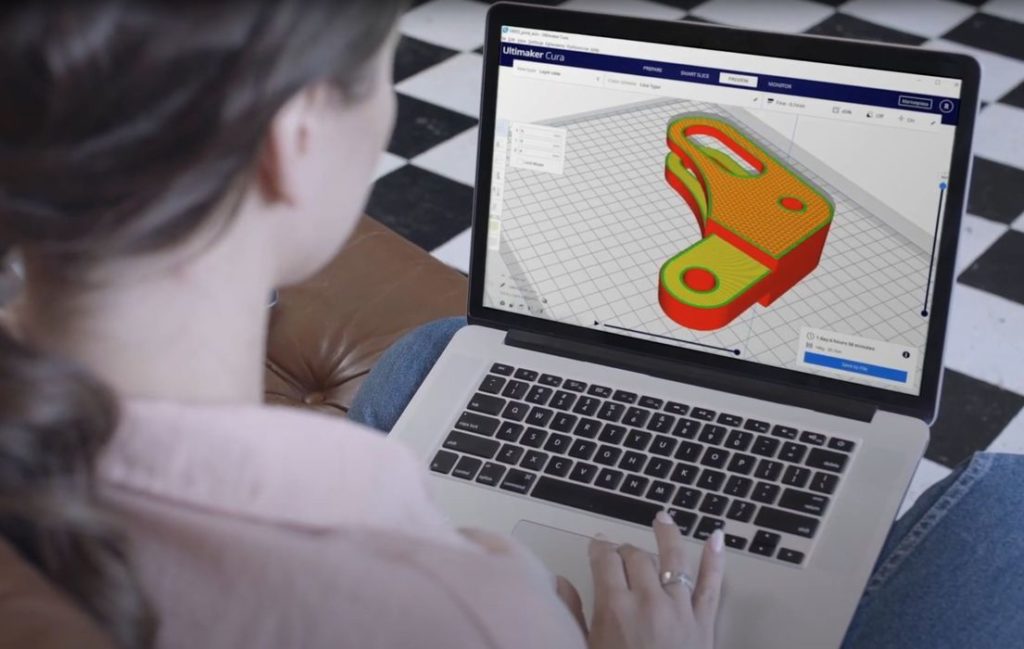

Teton Simulation is a software company that produces an advanced 3D print slicing tool. While there are plenty of slicers available, many for free, the key difference in Teton Simulation’s SmartSlice is that it incorporates FEA approaches into the slicing operation and can create complex extrusion paths that are optimized.

In other words, you’ll get a far, far better part when sliced with SmartSlice than a normal slicer. Even better, the company has been integrating this functionality into existing slicers, so at some point in the future you will automatically get better parts from your existing software — with a SmartSlice subscription.

3DQue

3DQue is a Vancouver-based startup that has developed a powerful system for intelligent bed adhesion. They’ve leveraged this technology into several forms, including upgrade kits for inexpensive desktop 3D printers, essentially transforming them into continuously-operating mini-factories.

The company now sets its sights on manufacturing, and has developed a printer-agnostic, AI-powered farm management system that can automatically recognize multiple forms of common 3D print failures through a vision system, and take appropriate action.

Seurat

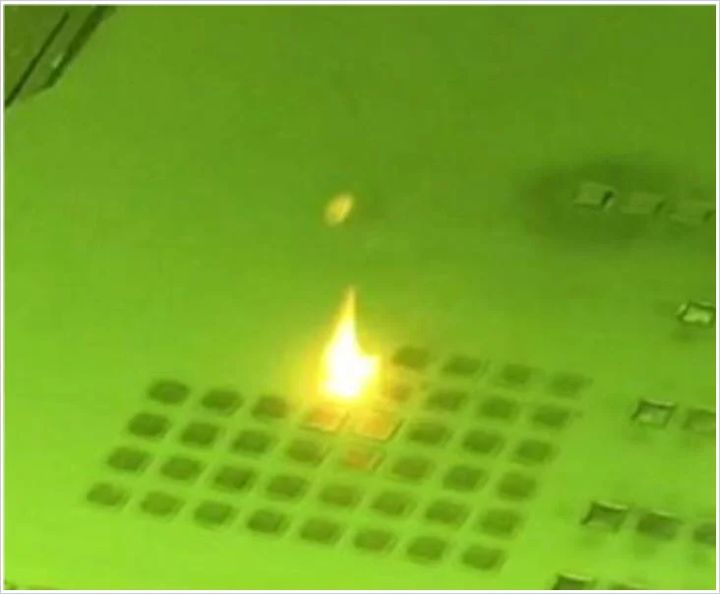

Seurat is a stealth company that’s only recently emerged from secrecy. They have developed a highly advanced form of metal 3D printing they call “Area Printing”. Basically it is a PBF system, except that entire areas are sintered at once, rather than tediously tracing a laser over the powder surface.

Their technology is highly scalable and appears to be able to produce parts far more rapidly than any other metal 3D printing process. Their technology is so powerful it may even compete with all traditional metal-making processes in the very near future.

BCN3D

BCN3D is a Spanish company that makes 3D printers. Starting from simple desktop units years ago, the company has recently been making a number of moves to gain traction and size.

They have added a number of industrial-capable devices to their lineup, enabling their entry into a much more profitable space. In addition, their acquisition of Astroprint has enabled them to almost instantly provide a powerful cloud-based management system for all client devices.

AMT

AMT is a UK-based maker of advanced post processing equipment for 3D printing. Several 3D print processes require notable amounts of post processing, and this must be done with great consistency if being done for end-use production parts. AMT’s intelligent equipment is able to do so, and do so at increasing speeds.

With the shift towards additive approaches by many manufacturers hoping to gain more control over unwieldy supply chains, AMT is in a very good position to capitalize on that transformation.

3DEO

3DEO is a Los Angeles-based company that provides a metal 3D printing service, specializing in smaller parts. Their proprietary technology uses standard metal powder, making it relatively inexpensive to produce parts using their approach, and is ideal for small to medium-sized batches.

3DEO has succeeded in the unusual approach of not selling their own hardware, and simply operating machines themselves in the form of a 3D print service. They have been so successful it is likely other companies developing new 3D print processes may consider doing the same.

nTopology

nTopology is a software company that develops a powerful CAD tool that can handle extraordinarily complex 3D models that would otherwise choke normal 3D software. This is an essential capability for 3D printing, where complex parts are how the technology actually provides significant benefit.

The hardware requires advanced software, and nTopology provides the software half. As competition among those using 3D printing increases, so will the requirement for handling very complex 3D models. nTopology has a solution.

Xolo

Xolo is a startup company developing the highly unusual technology of volumetric 3D printing. This process is much like a “reverse CT scan” process, in which light is projected into a clear cylinder of photopolymer resin. Objects can be created in mere minutes and seconds, literally 100X faster than conventional 3D printing processes.

The rapid volumetric process should eventually take over from many resin approaches, and Xolo has been developing the technology for several years.