Researchers have found a way to decompose PET material.

PET, (or its more common relative PET-G) is one of the more popular 3D print materials, along with PLA, ABS, and ASA. It is relatively easy to print, and doesn’t warp too much. It also offers a shiny texture that can be quite attractive.

It’s also one of the world’s worst materials for microplastic pollution. PET is commonly used in drink bottles due to its durability, safety and clear appearance. These bottles are littered everywhere, in spite of recycling programs. The bottles mechanically break down into small bits that add to the microplastic problem.

Researchers have been looking for ways to decompose PET and other microplastics for many years, and have identified a number of natural bacterial enzymes that can degrade the material. However, most of them act very slowly and thus are not particularly useful for widespread action.

They investigated a particular enzyme produced by a deep-sea bacteria and amazingly found that it was able to hydrolyze PET material.

If you have visions of scientists at the bottom of the ocean with microscopes studying muck for bacteria, that’s not how it works. Instead they performed a data search. There are huge databases of genetic information collected from living environments, which can be searched for specific attributes.

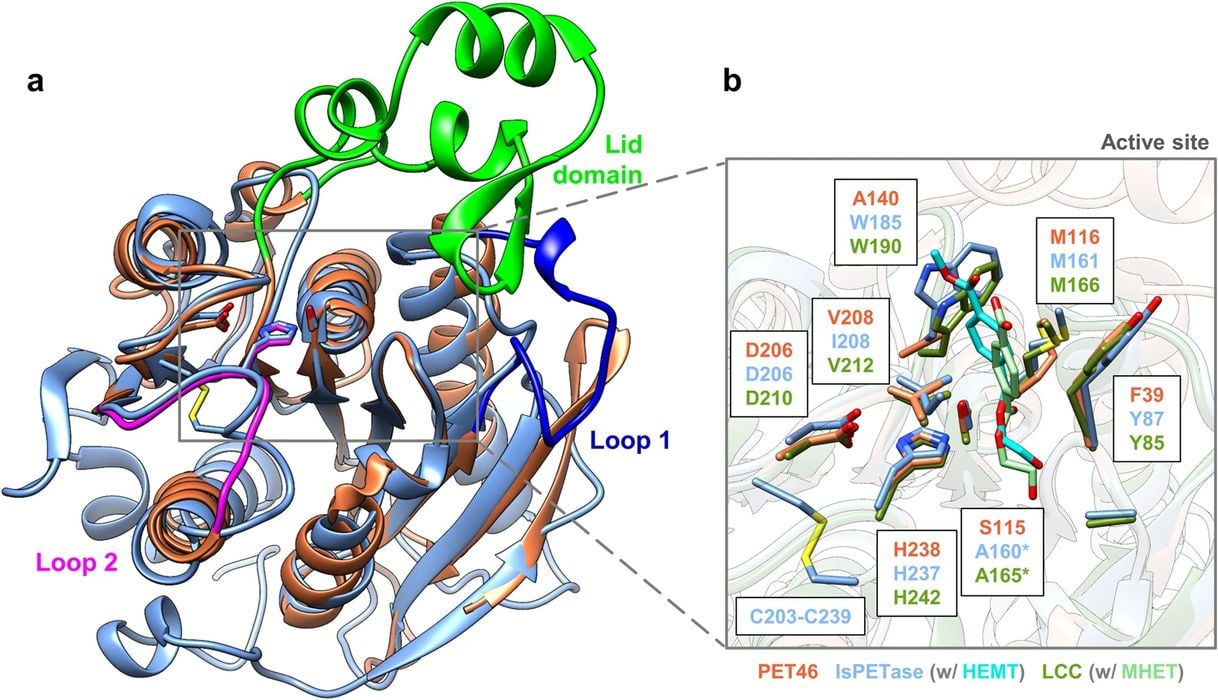

The researchers performed a 3D model analysis to find genetic sequences that might be suitable for PET hydrolization (note image at top). Eventually, they identified a sequence in strain Candidatus Bathyarchaeota archaeon from the Guaymas Basin.

They tested a variety of PET polymers, and found that hydrolization did occur with modest environmental conditions.

They write that they believe there are more enzymes that can perform this effect, beyond data and on site inspections. That suggests it may be possible to engineer substances that can hydrolyze PET and possibly other plastics.

This is good news for 3D printing because it may ultimately lead to a method of properly disposing of PET prints. Today they are simply sent to the landfill, where they add to the microplastic problem. However, if new enzymes are used in bioreactors to process PET at recycling centers, then we might have a way forward.

This isn’t just for 3D printing. Recall those drink bottles? I can imagine recycling centers set up specifically for them, but as a side effect being able to handle PET 3D prints as well.

Via Nature