New research shows a potential path to significantly reduce petrochemical-based plastic use, possibly including in 3D printing.

The majority of today’s common plastics are derived from petrochemical sources. This is known to be detrimental to the environment during production, and the resulting plastics tend to be near-indestructible. The vast majority of plastic produced ends up in landfills or the ocean, where it breaks up into microplastic bits that ultimately pollute our food supply. We are all slowly absorbing random chemicals from these plastics.

The answer would be to stop using these materials, but that’s effectively impossible due to widespread use and dependence on them. If only there were another approach for creating plastics.

That could be the case with new research from the University of Konstanz in Germany have developed a new form of mineral plastic that’s both biodegradable and self-healing.

Hold on, what’s a “mineral plastic”?

Conventional plastics are typically derived from petrochemicals (i.e., petroleum and natural gas). They consist of polymers, long chains of repeating molecular units, which give the material its plastic properties. Common examples of such plastics include polyethylene, polypropylene, polyvinyl chloride (PVC), and polystyrene. These materials are not biodegradable, meaning they do not break down naturally in the environment. This leads to significant environmental issues, such as pollution and harm to wildlife.

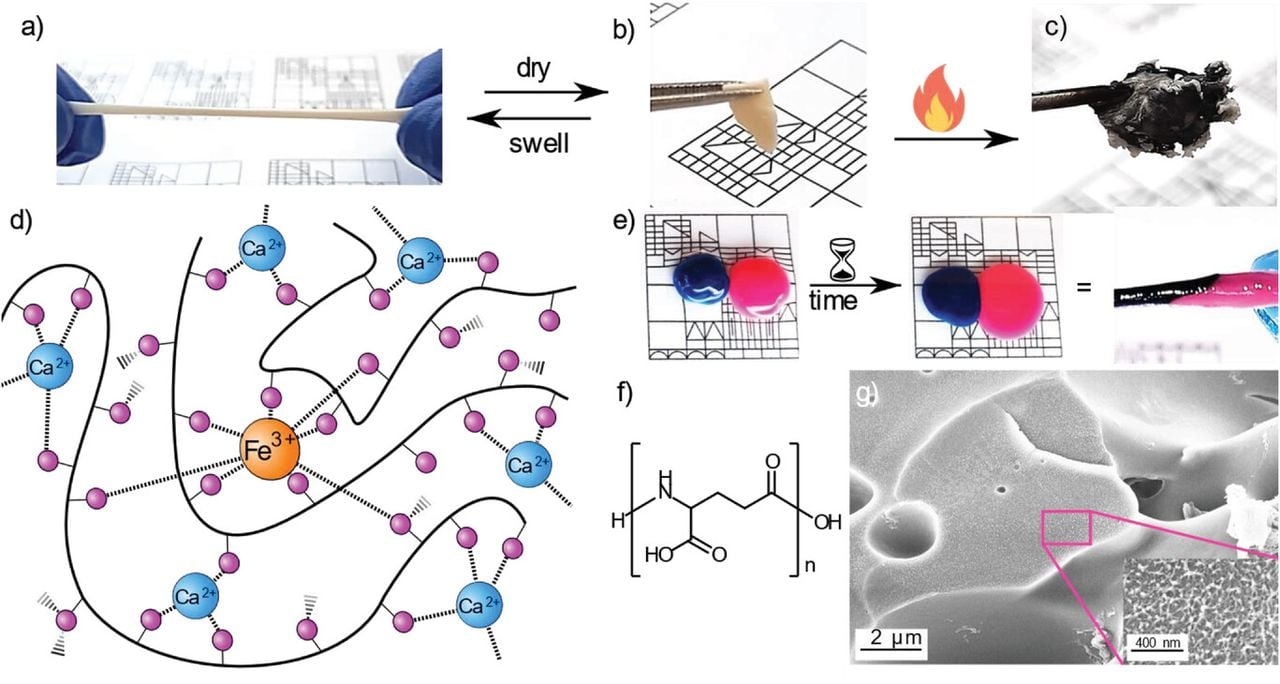

On the other hand, mineral plastics are a relatively new class of materials that are bio-inspired. They are made by combining minerals with polymers, which can give them exceptional properties, such as self-healability, stretchability in the hydrogel state, high hardness, toughness, transparency, and non-flammability in the dry state. Furthermore, they can be transformed reversibly into a hydrogel by adding water, making them easy to reshape and recycle.

The new material is a physically cross-linked (poly)glutamic-acid (PGlu)-based mineral plastic. The researchers synthesized these plastics using various alcohol-water mixtures and metal ion ratios, thus providing a more sustainable and environmentally friendly alternative to conventional mineral plastics.

At this point, this is simply a new class of plastics that has not yet been considered for use in 3D printing. Should interest in the material grow, this could change.

Could this material be used in 3D printers? It would seem that self-healing plastic would be extremely desirable for printing objects. That property alone might increase print quality by automatically sealing holes occurring in poor print jobs.

The specifics of whether and how these materials could be used in 3D printing would likely depend on various factors, such as the exact properties of the mineral plastic, the type of 3D printing technology used (e.g., fused deposition modeling, stereolithography, selective laser sintering, etc.), and the requirements of the object being printed.

Based on the description of how the material can be reshaped, it is highly unlikely it could be used on today’s 3D printers, either as a new filament type or powder. It would seem that a new type of 3D printing process might be required to properly use this unusual material.

That could be a lot of effort to do, but on the other hand the world must move away from petrochemical-based materials and to do so major changes will be required.

Via Wiley