E3D has been making progress with their updated product set.

I spoke with an E3D representative recently to find out more about their fascinating Revo hot end system.

The Revo system is a greatly simplified design for hot ends that enables great performance and significantly easier operations than typical hot ends. For example, you can swap out a nozzle with one hand without the requirement for heating the nozzle.

The system is definitely innovative, but there are some challenges, albeit not technical in nature. E3D’s prior products were open sourced, in particular the very popular E3D-v6 hot end design, which has subsequently become a standard among most 3D printer manufacturers.

However, the uniqueness of the Revo system caused E3D to tweak their licensing terms. Basically they’ve set it up so that the cold side of the hot end is open source, while the hot side remains their intellectual property. This was done as a matter of survival for the company, as it is a near certainty that the Revo’s unique design would be mass produced and sold by others, cutting out much business for E3D.

That said, E3D is proceeding well with the Revo. The company announced a couple of new versions of the Revo recently.

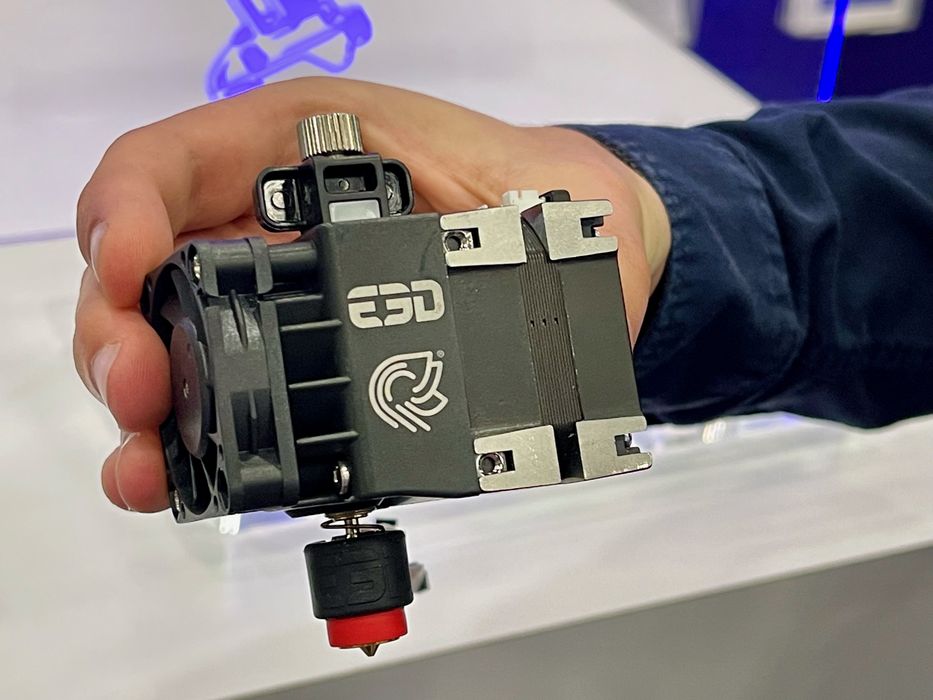

One is the Revo Hemera XS, a Revo version of their popular Hemera extrusion system. Seen at top, the system is almost 100g lighter than the previous Hemera. This should allow operators to raise the speed of the printer’s motion system a bit, as there is less inertia to overcome during directional changes. Of course, all the normal benefits of the Revo system are also present.

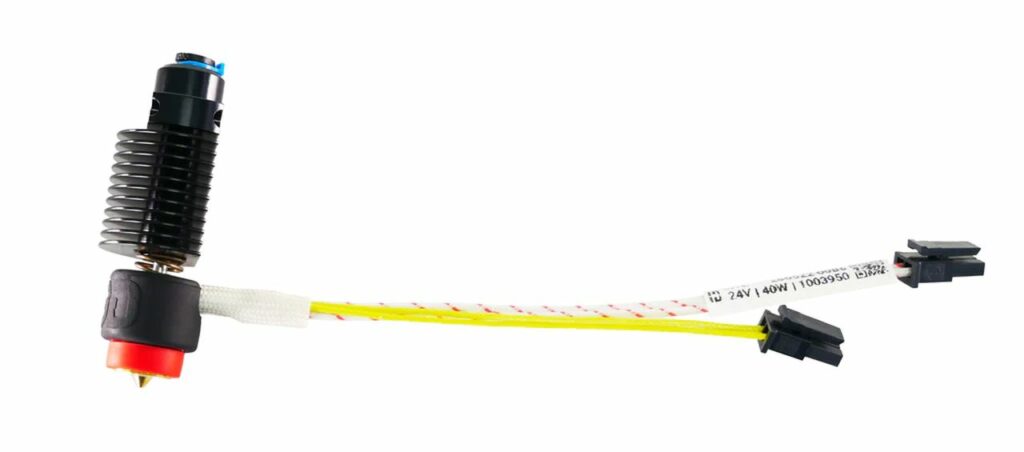

A very intriguing recent development is the release of the Revo CR, a hot end replacement for Creality 3D printers. Creality is likely the manufacturer producing the most units these days, and many of them could potentially be used in Creality Enders, CR-10s, etc. E3D explains:

“Thanks to this Creality-specific Heatercore and the inclusion of butt splice connectors, to install Revo CR you don’t need to touch any firmware or even open your wiring loom. In fact, the upgrade can be done in as little as 5 to 10 minutes.”

E3D also has similar offerings for BIQU equipment and the popular Voron kit 3D printer.

One of the most interesting entries in the Revo series is the Revo Micro, which might be the lightest hot end ever at only 30g. With this component, operators might be able to achieve considerable speed advantages and still produce quality prints.

For the future, there are plenty of plans for E3D. One is the intent to make a Revo version of their ObXidian nozzle, which is much harder than standard brass nozzles. This will permit longer usage when printing abrasive materials like carbon-fiber reinforced filament.

Finally, I asked E3D whether they’ve changed their company name. The actual name of the company is “E3D-Online”, but in recent times I’ve increasingly seen them officially branded as the much-easier-to-type “E3D”. Evidently they have been officially rebranding, but in a quiet manner. But we noticed, and think it’s a good thing and henceforth we shall call them “E3D”.

Via E3D