E3D-Online announced a resumption of production for their advanced Hemera 3D printer extruder.

The product was first announced in November 2019 and was seen as one of the most advanced solutions for 3D printer extrusion. Hot ends and extruders are by far the most critical elements of any 3D printer, as even subtle issues can cause print failures or lower print quality. E3D has become one of the leaders in the industry for providing high-quality solutions in this area, to the point where they are almost the de facto solution for many 3D printer manufacturers.

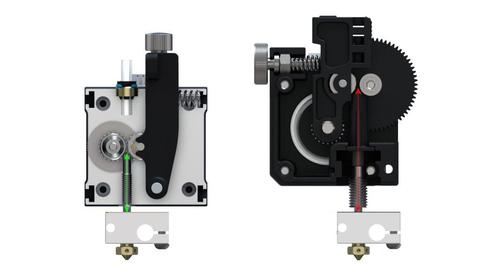

The design of the Hemera is quite interesting as it addresses a number of ongoing issues seen in many competing extruders:

Dual-drive

Like many extruders, the Hemera features dual toothed gears to bite into and push the filament forward. However, the Hemera’s teeth are specially CNC milled to be not only sharper, but also shaped to avoid collecting debris.

Directed Cooling

The heat sink is cooled by fans, but E3D has devised a unique ducting system that not only cools, but directs this airflow away from the print itself. This allows more complete cooling control of extruded materials.

Jam-Proof Filament Path

In most extruders there is a gap of several millimeters between the drive gears and the hot end orifice. This gap is highly problematic as it allows space for a filament to slightly twist and jam. This is particularly challenging for flexible filaments. However, the Hemera design positions the orifice right where the drive gears separate, leaving effectively no space for jams to occur.

Long Service Life

E3D has included a number of very high-quality components in the Hemera to extend its service life. For example, sealed bearings prevent debris from fouling their motion. Drive gear teeth are shaped to self-clean, as are other parts. New lubrications ensure parts move more smoothly. All of these and other improvements will ensure the Hemera lasts a very long time.

Easy Mounting

The mounting system for the Hemera is designed to easily attach to NEMA-17 motors systems on a wide variety of 3D printers. In fact, the company has posted detailed text or video instructions for upgrading over a dozen popular desktop 3D printers.

Here is a video overview of the Hemera system from E3D:

It’s no surprise that the Hemera proved quite popular and E3D was swamped with orders.

Hemera Production

However, two things happened since the product was released.

First, a very few customers had issues with drive gears, requiring replacements.

Secondly, the pandemic happened. This broke E3D’s supply chains, and they were unable to properly fulfill orders and in some cases even ship replacement parts for the first issue. I’m not surprised this happened, as all companies have been subjected to supply chain issues this past year.

But now there’s good news! E3D announced they have restored their supply chains — and improved them to allow for much higher volumes. They say there will be “no delays”.

Secondly, they took the time to rework their production process to become more efficient and also fix the drive gear issues. This ultimately turned out to be the choice of steel used, and required the addition of some new lubricants.

E3D CEO Sanjay Mortimer said:

“We’ve spent months painstakingly unpicking the bottlenecks in our manufacturing process that were preventing us being able to make an incredible extruder consistently at the scale we now operate at. By diving deep into the minutia of heat-treatment atmospheres, automated grease dispensing robots, and multi-axis machining, we’ve been able to fix everything that was holding us back.

I’m so proud of the team for pulling this off in such adverse circumstances, while still ensuring that we got prototyping, testing, and scaling done right. I’m happy to say that I’m now equally as proud of the product after this monumental effort.

My personal apologies go out to all those who have been waiting for what has felt like an age, and to those we’ve had to ship replacement parts to get back up and running. I’m now more confident in this product than anything we’ve ever released, and I’m looking forward to seeing what our customers do with it!”

The result of all this is that everyone should be able to order and receive a fully functional Hemera extruder as of today.

I’m hoping some (or more than some) 3D printer manufacturers adopt the Hemera as a standard feature, as it should dramatically increase the reliability of operations of any 3D printer.

Via E3D-Online