After the blockbuster announcement of Ultimaker Cura 5.0, I decided to give it a quick test.

Ultimaker Cura is one of the most-used 3D print slicing system on the planet, if not the most used. It’s open source distribution allows 3D printer manufacturers other than Ultimaker to prepare customized versions of the software for their platforms, making it far more popular than an Ultimaker-only product.

The latest version of Ultimaker Cura, version 5.0, has been released in beta form for the more adventurous 3D printer operators to test. While on the surface it is much the same as prior releases, there are big changes on the inside.

The major change is in the core slicing engine itself, the code that produces the extrusion paths that form the bulk of the generated GCODE that executes on 3D printers.

The major feature is an ability to handle thin walls more correctly. Earlier versions of Ultimaker Cura would stumble when building walls with dimensions that weren’t multiples of the base extrusion width, typically 0.4mm for standard nozzles.

A 1.8mm wall, for example, would end up with four extrusion perimeters of 0.4mm, totaling 1.6mm, and a 0.2mm gap. There are, of course, pathological examples of this effect, which can happen throughout almost any 3D model. It’s particularly apparent on complex and detailed 3D models with plenty of thin parts.

The new slicing engine in v5.0 accounts for this and dynamically adjusts the extrusion width to more properly fill in the gaps. This makes for stronger parts as they are more solid with far fewer gaps.

I put this to the test with a 3D model sliced with both v5.0 and an earlier v4 system.

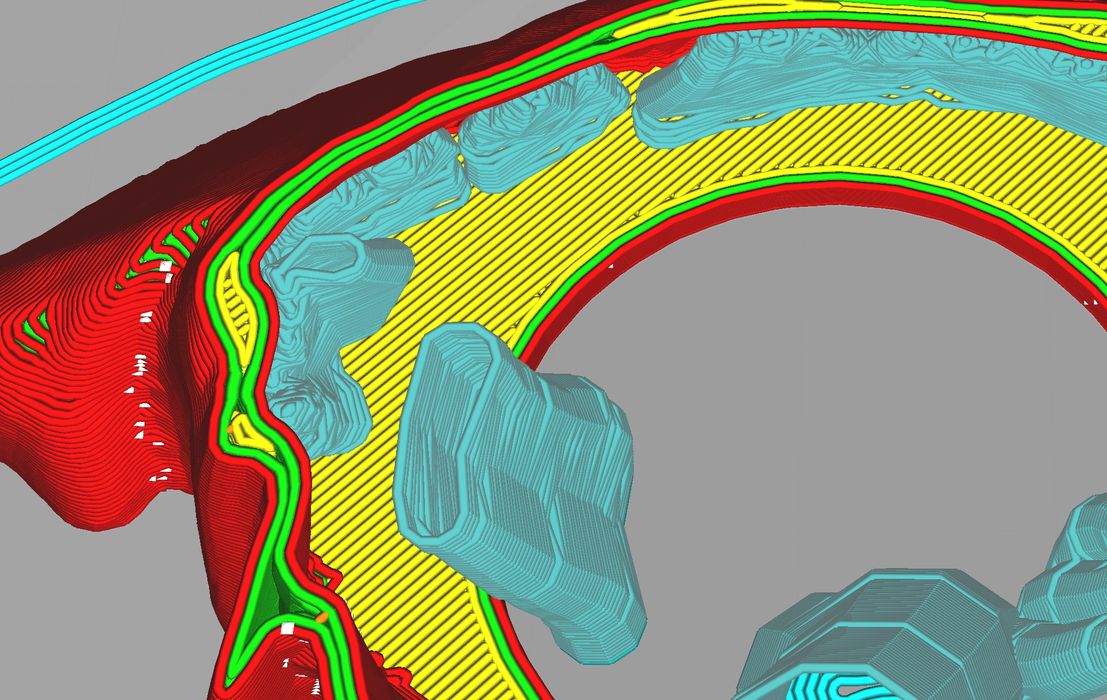

Here’s a portion of a layer’s tool paths as generated by Ultimaker Cura v4:

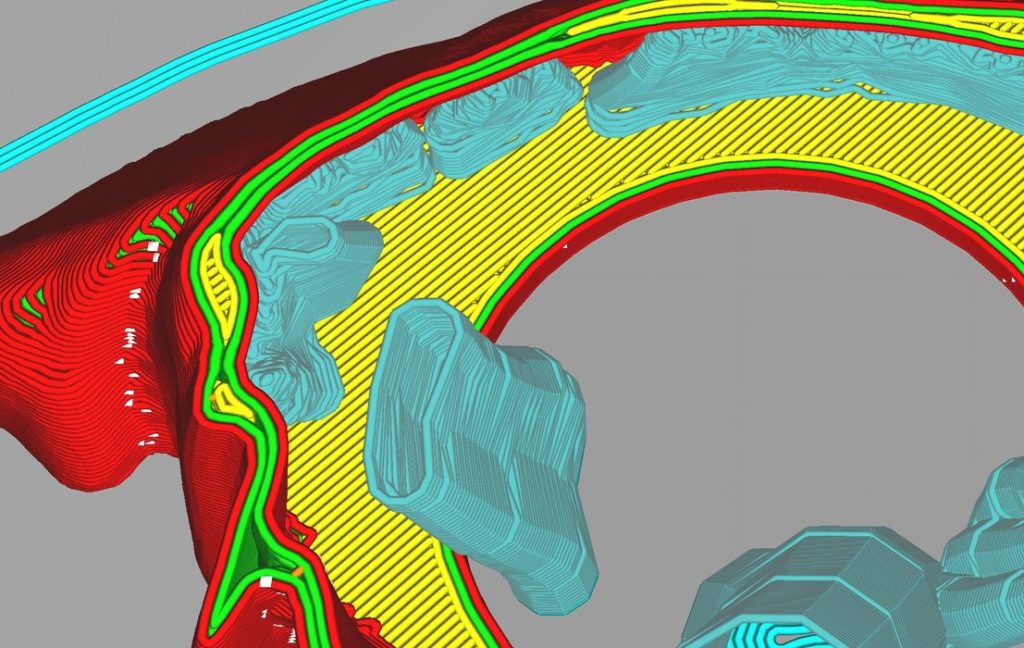

And here is the same 3D model, with the same general print parameters sliced with v5:

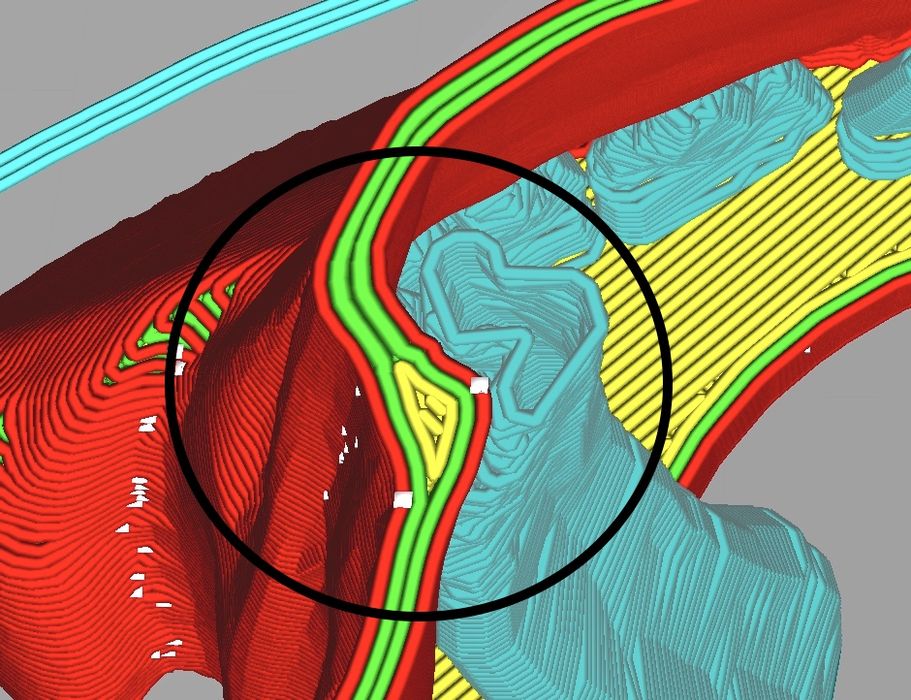

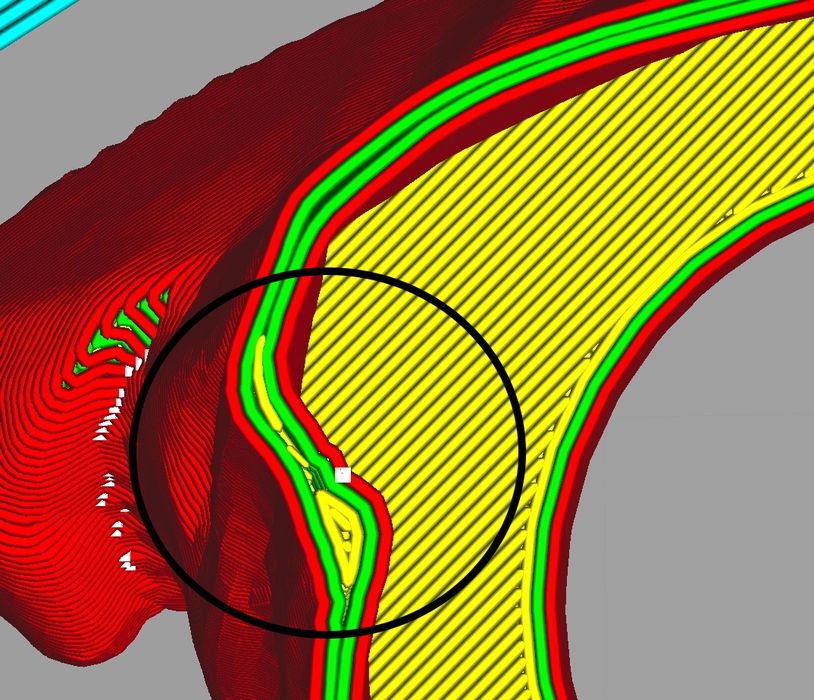

There’s several things to note here. I draw your attention to the black circled area in each image.

In the v4 image, we can see there is a yellow area that requires some extra perimeters, and some green extrusions above it. However, you can see that between the green extrusions there is a bit of a dark area, indicating a slight gap.

In the same area on the v5 image, we can see those dark gaps have been filled with an extra bit of extrusion, making that part of the model more solid.

Similarly, in the yellow triangular area, you can see gaps in the v4 image, but they’re better filled in on the v5 image.

Ultimaker Cura v5 definitely prepares better GCODE for stronger parts.

There’s another interesting effect that can be attempted with v5. Normally any structure smaller than the minimum extrusion width simply cannot be 3D printed. In our above example, if we had a wall less than 0.4mm, the width of the nozzle, it would be sliced as a gap by v4.

But v5 can make smaller extrusions, as you can see in the lower image. It does this by a combination of movement and filament flow.

The ability to make smaller extrusions means you can print with far more detail than otherwise achievable.

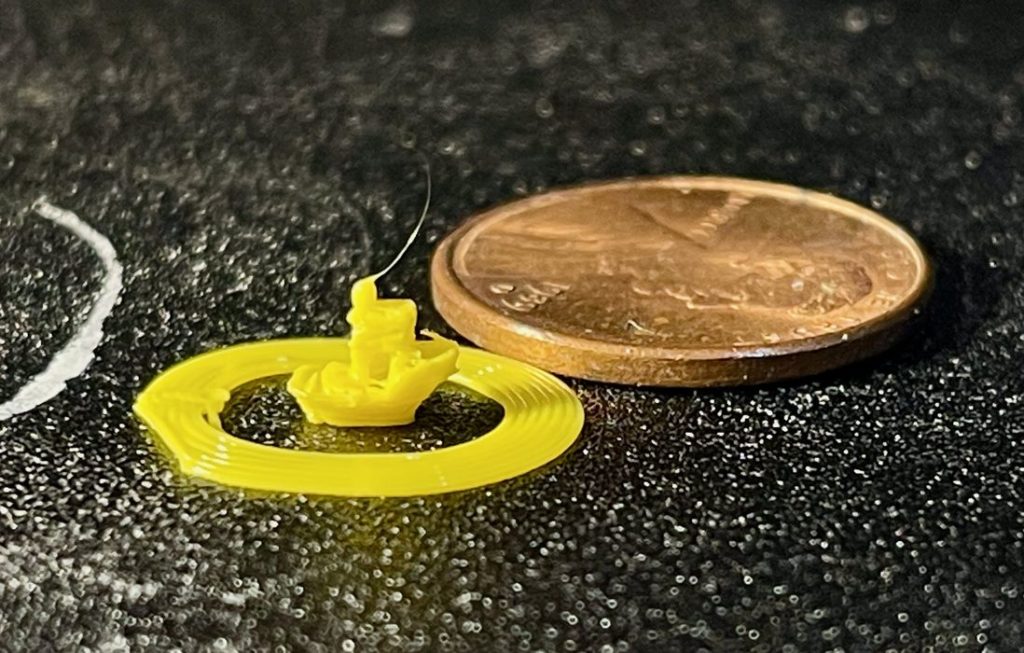

And you can also 3D print objects far smaller than ever before. To put this to the test I decided to 3D print a #3DBenchy, the standard test object. But at only 10% of its normal size. This meant the little boat would be only 6mm in length, and only 3mm wide, with many details even smaller.

Could Ultimaker Cura v5 successfully slice this object?

It did, and I printed it with 0.06mm layers on a Creality Ender 3D printer. The result:

That is by far the smallest #3DBenchy I’ve ever 3D printed on a FFF device. It’s not the greatest print, but it is definitely a little boat.

Please give Ultimaker Cura v5 a test yourself, and see what tiny things you can 3D print.

Via Ultimaker