Digital Metal launched a new metal 3D printer, and there’s some interesting implications.

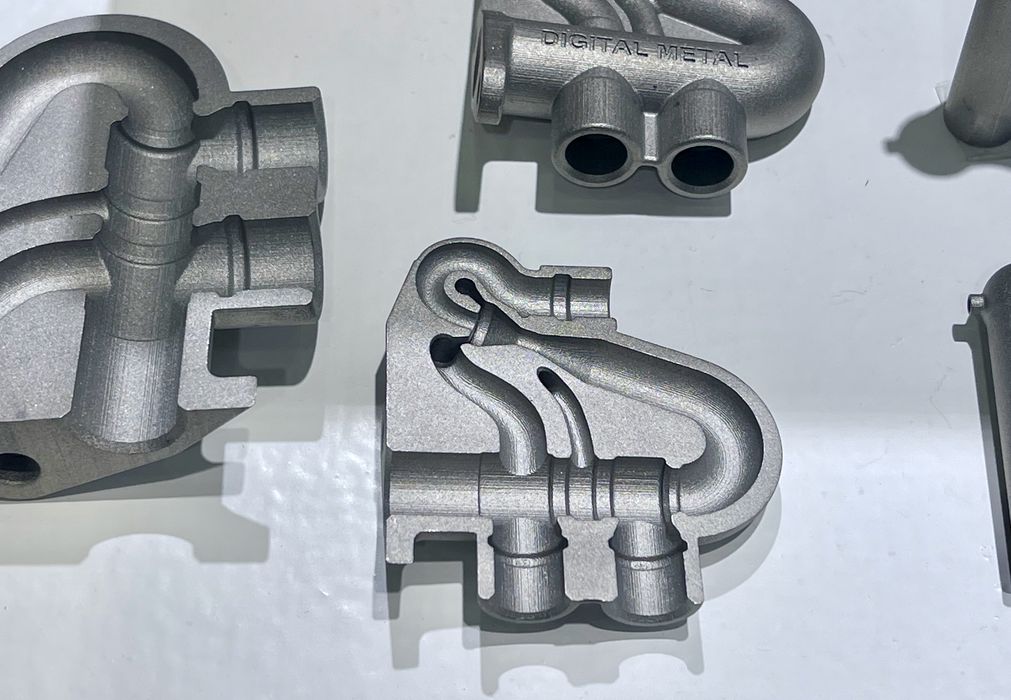

The result as the DM P2500, a rather unusual 3D printer. It uses a cold binder jet approach to printing, and produces green parts that require sintering in the post processing sequence. The most notable aspect of their technology is its ability to produce extremely fine details, far more than any other metal 3D printing system I’ve yet seen.

If you’re not familiar with Digital Metal, they are the 3D printer manufacturer arm of Höganäs, a long-time Swedish producer of fine metal powders for industry. After observing their powder clients grow significantly as metal 3D printing was increasingly adopted, they decided to make a metal 3D printer of their own.

For example, this detailed copper part is only 10mm across. Also note that copper is a metal that is not 3D printable on most metal devices, but Digital Metal can handle it easily. The company is currently able to print in 316L, 17-4PH, Ti6AI4V, DM 625, DM 247, DM D2, DM 718, DM 4140 and DM Cu, some of which are custom designed alloys by Digital Metal themselves.

This item, a component for a watch is also very interesting. It is a highly detailed object, but let’s zoom in on an alignment pin at the top of the print:

That pin, which is basically invisible to the eye, is only 0.3mm tall. You can barely feel it with a finger, but otherwise it’s not noticeable.

Anyhow, you get the idea: Digital Metal 3D printers can produce metal objects with the most resolution I’ve yet seen.

Recently the company announced a new 3D printer, the 70kp84, part of their new DM/PRO line.

The machine features a 160mm thick granite stone as the print base, which should provide extreme rigidity. They’ve also developed a new print head that includes 70,400 nozzles, whereas their old print head had “only” 1200.

The massive increase in nozzles means they can print an entire layer in a single pass, rather than requiring multiple passes in previous equipment. This should mean much faster printing.

The new nozzle system enables the device to despot 2pl droplets and achieve 8000 x 1600 dpi.

Indeed that is true, as they say the new device can 3D print between 500 to 1000 cubic centimeters of metal each hour.

With the increased resolution on the 70kp84 and the increased speed, one wonders what possible application areas could be opened up by this machine. The parts produced by Digital Metal equipment have extremely good surface quality right out of the machine, and those produced by the new equipment should be even better.

I suspect the new gear may find its role producing small but extremely intricate heat exchangers, where there are plenty of internal heat cavities that cannot be easily polished with post processing equipment. These surfaces might be smooth enough to allow for proper operation, even without surface processing.

I also wonder if Digital Metal is contemplating building a machine with a larger build volume. If so, they could quickly compete with other larger-sized metal production systems that require more post processing.

Via Digital Metal