Diamond Age announced a massive US$50M investment, which could have a huge effect on construction 3D printing.

Construction 3D printing has evolved to the state where concrete extrusion is used to rapidly create walls, floors and certain other portions of a structure. It does not, however, do much else.

The majority of the work on a so-called 3D printed building is actually done using conventional trades, materials and techniques. To be clear, there are advantages to producing the concrete portions with construction 3D printers, but that’s really the only part done with 3D printing. This often goes unmentioned by mass media stories claiming a “house was 3D printed in 24 hours.”

If only there was a way to do more of the construction project using 3D printing or other robotic means. If so we could see more construction steps sped up, and more unusual designs taking place that take advantage of automated processes.

Look no further than Diamond Age, a California construction 3D printing startup that has recognized this deficiency in the current state of construction 3D printing. Their approach to solving this dilemma is brilliant.

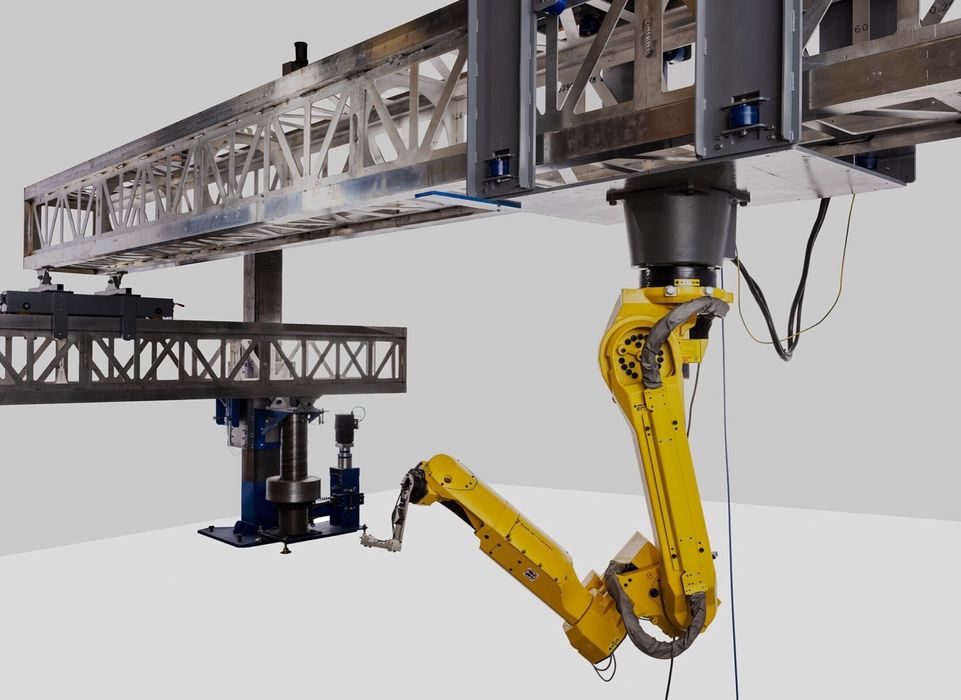

Normally a construction 3D printer will use a large gantry to enclose the build volume, wherein concrete will be extruded to the desired shape. That’s usually the end of the story, but Diamond Age has a different idea.

Instead of tearing down the gantry and allowing trades to complete the work, they simply swap in new toolheads for the motion system on the gantry.

One example is a concrete sawing system that would cut windows in the extruded concrete, which would normally be done with manual intervention on other construction 3D printing systems.

Another example could be to pick and place components that require installation, thereby automating some work normally done by manual labor.

In all, Diamond Age said they can potentially use 26 different toolheads on their system. To me, that sounds like enough to do a huge amount of different jobs on a construction site.

Previously the company had received US$8M in investment, but now they’ve announced a new investment round of US$50M. The investment partners, led by Prime Movers Lab, is mostly a series of VC firms. There are no 3D printing investors as far as I can tell.

For Diamond Age, this amount would certainly provide more than sufficient resources to build out the key portions of their technology. If they are able to demonstrate the utility — which need only be the ability to automate more portions of a construction project — then they are in a position to grow rapidly and receive even more investment.

Construction 3D printing competitor ICON has already received nearly US$500M in investment, and this demonstrates the tremendous interest in this form of 3D printing by the investment market. Diamond Age’s approach seems to allow for additional efficiencies, and thus might eventually attract similar levels of investment.

However, with the money in the bag, the onus is now on Diamond Age to demonstrate their capabilities.

Via Diamond Age and TechCrunch